Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

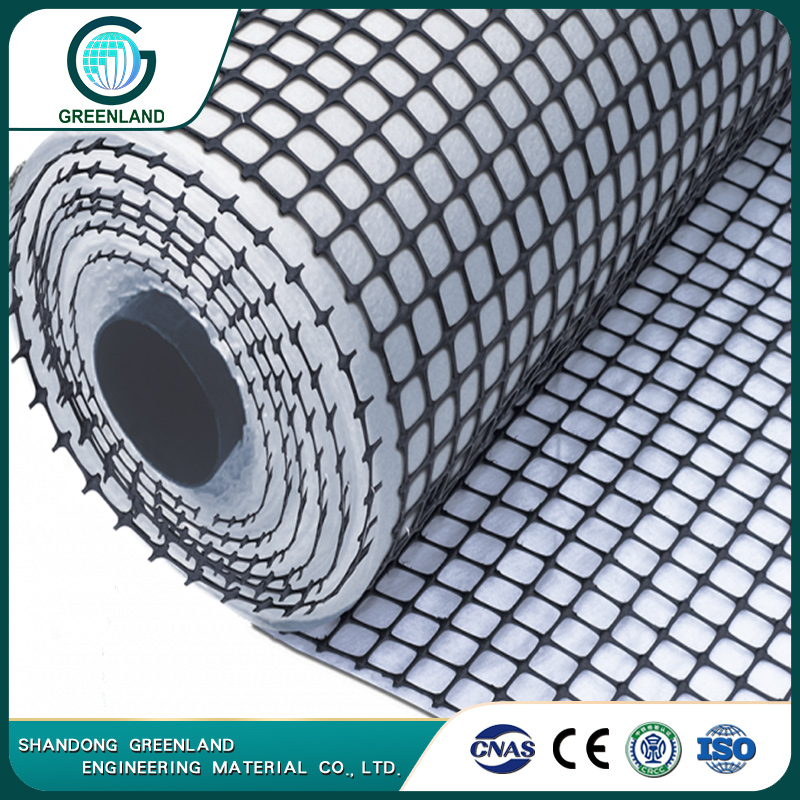

Geocomposite

- 1.Thickness: Customized

- 2.Width: Max. 8M

- 3.Raw Material: Geotextile-Geonet, Multi-Linear Drainage Composites, Geotextile-Geomembrane, Geomembrane-Geogrid, Geotextile-Geogrid, Geomat, etcs…

- 4.Standard: ASTM, GRI, ISO, GB-T

- 5.Delivery: Stock for regular item, 5-10 Days for Production

- 6.Packing: 50-100m length/roll, Customized

- 7.MOQ: Trial order is acceptable

- 8.Free Sample Available

Geocomposites are combinations of two or more geosynthetic materials for civil engineering applications that perform multiple geosynthetic functions, the five basic functions are: separation, reinforcement, filtration, drainage, and containment. Such composite materials may enhance technical properties of the soil or the geotechnical structure and minimize application costs.

Quick Details of Geocomposite

Quick Details of Geocomposite

| Products details information | |

| Product name | Geocomposite |

| Brand | Greenland (OEM is available) |

| Thickness | 0.2-4.0mm(20 mils-120 mils) |

| Raw material | Geotextile-Geonet, Multi-Linear Drainage Composites, Geotextile-Geomembrane, Geomembrane-Geogrid, Geotextile-Geogrid, Geomat, etcs... |

| Application | Separation, filtration, reinforcement, and drainage |

| Color | Black, White, other colors |

| Standards | ASTM, GRI, ISO, GB/T |

| Welding Tools | Hot air welding gun, geomembrane welding machine, etc |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

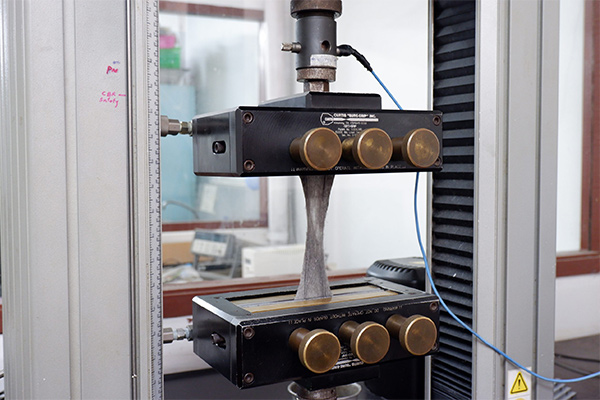

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

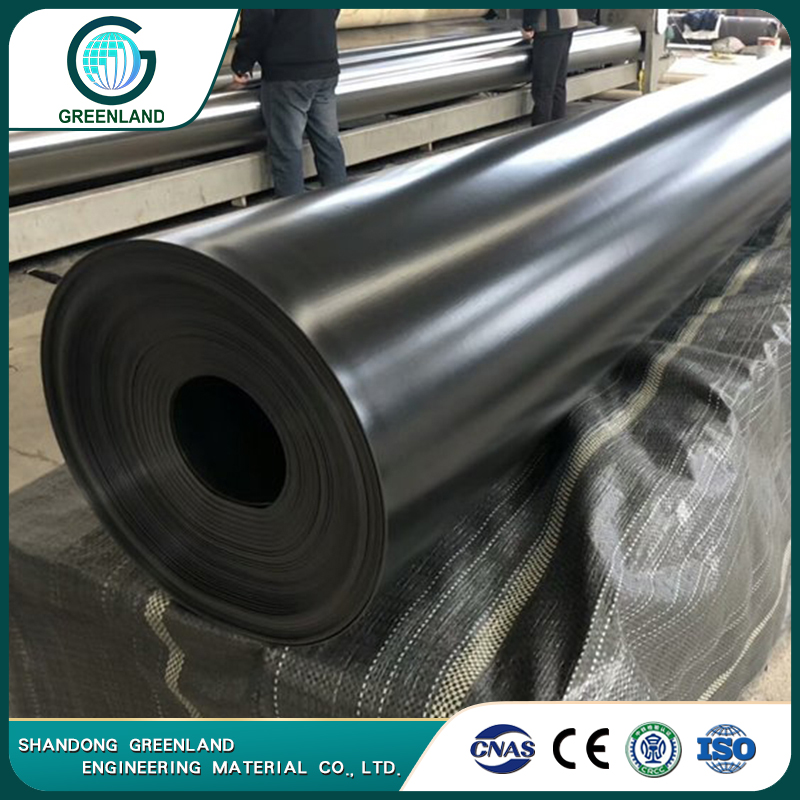

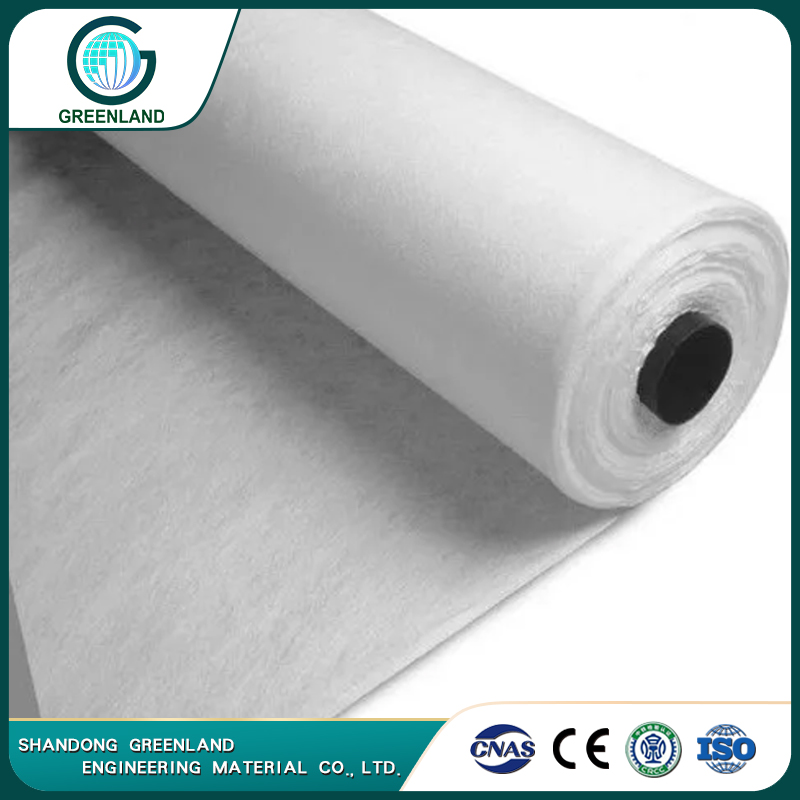

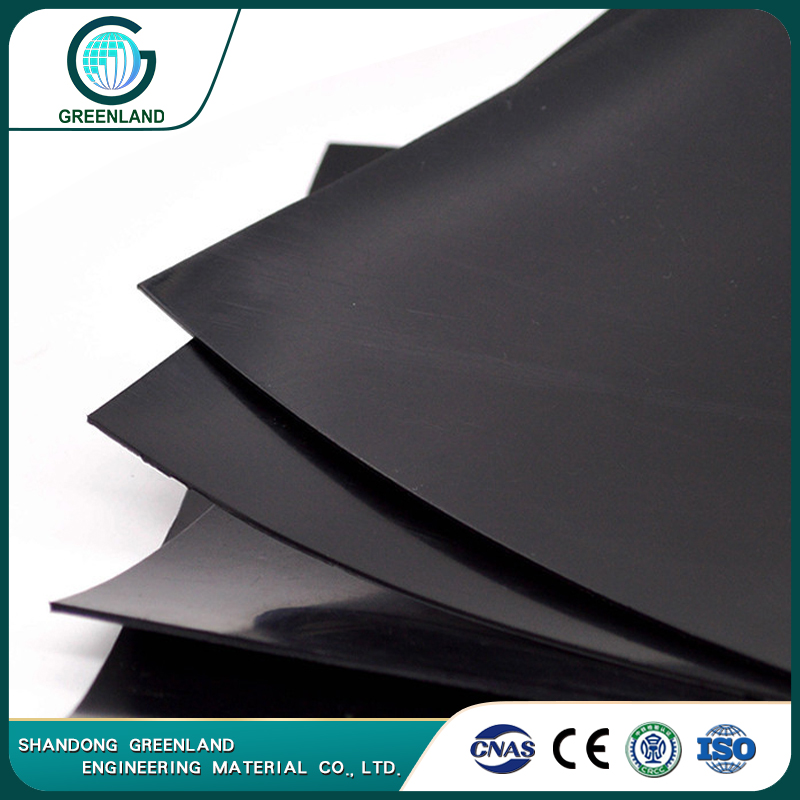

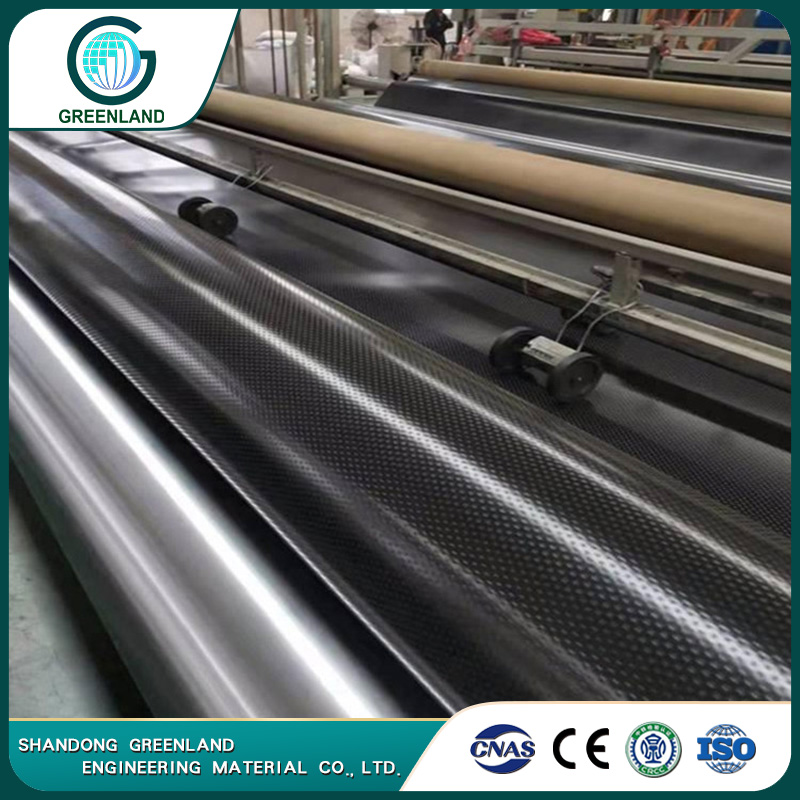

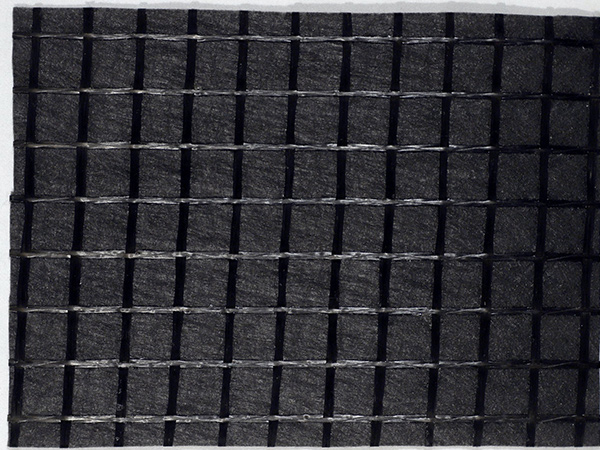

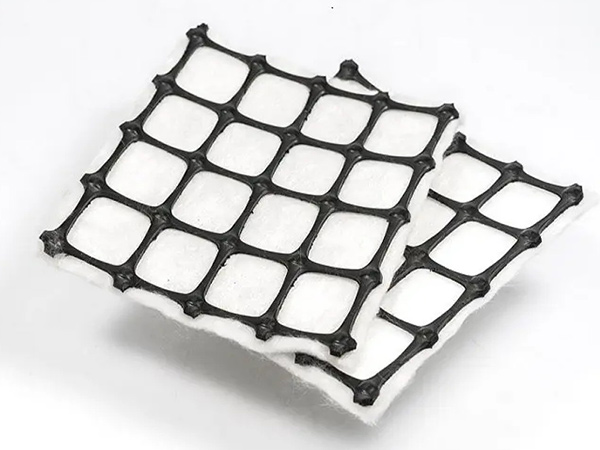

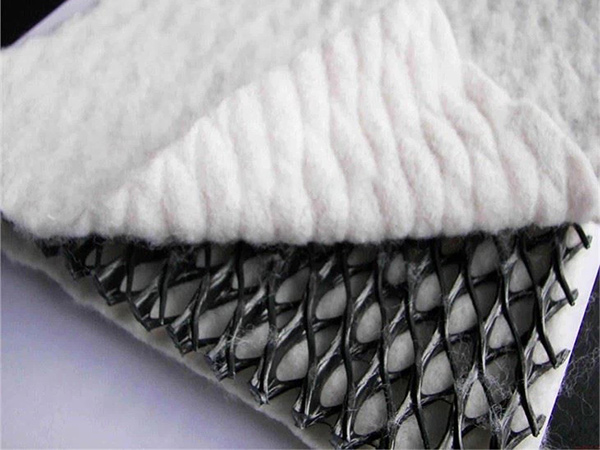

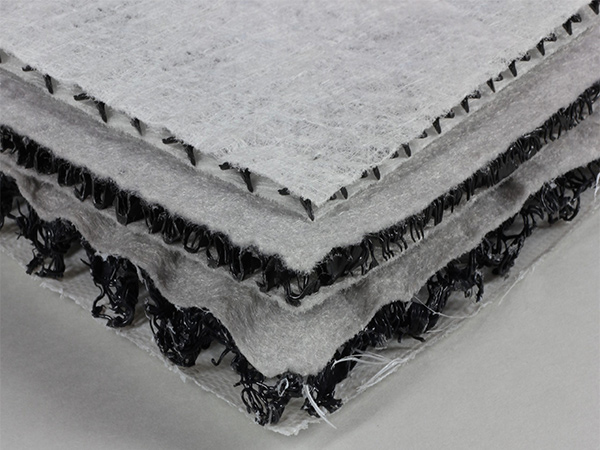

Different Materials for Geocomposite

Different Materials for Geocomposite

Geocomposite is the union of two or more geosynthetics by lamination, mechanical process (like needle punching) or by using adhesives, combining their characteristics in a single end product to produce multifunctional materials.

The Most Commonly Used Type Of Geocomposite

The Most Commonly Used Type Of Geocomposite

| ❖Geotextile-Geonet Composites | ❖Geomembrane-Geogrid Composites | ||

| ❖Multi-Linear Drainage Composites |

❖Geotextile-Geogrid Composites |

||

| ❖Geotextile-Geomembrane Composites |

❖Geotextile-Polymer Core Composites |

||

| ❖Geocomposite Drain Mat |

❖Other Customized Composites |

❖The membrane could be Smooth Geomembrane, Textured Geomembrane, and the geotextile will be non-woven or woven geotextiles, so many options for your chioces.

The Geocomposite is the union of two or more geosynthetics by lamination, mechanical process (like needle punching) or by using adhesives, combining their characteristics in a single end product to produce multifunctional materials.

Different Kinds of Geocomposite

Different Kinds of Geocomposite

Sometimes different functions of various product groups are needed simultaneously in a single application. In these and many other cases, complex, multi-layered challenges arise. Earthworks for road and traffic route construction require multiple products for separation, filtration, draining, reinforcement, protection and sealing. Geocomposites combine several individual geosyntheses. It also arises by combining geosynthesis with other materials. The result is a high-performance product that combines two or more functions in a single product.

|

|

|

| Geotextile-Geonet Composites | Geotextils-Geogrid Composites | Multi-Linear Drainage Composites |

|

|

|

| Geotextile-Geomembrane Composites | Geomembrane-Geogrid Composites | Geotextile-Polymer Core Composites |

|

|

|

| Geotextile-Geonet Composites | Geotextile-Geogrid Composites | Multi-Linear Drainage Composites |

|

|

|

| Geotextile-Geogrid Composites | Geotextile-Geonet Composites | Geocomposite Drain Mat |

❖Please Contact US and Get a Solutions of the Composte Geomembrane Liner Now.

Benefits of Geocomposite

Benefits of Geocomposite

The use of composite geotextiles provides several benefits. They enhance functionality, increase interface friction angles, speed up installation, and provide superior separation, cushioning, reinforcement, and drainage capabilities. They affectively control pollution during dredging operations by using floating silt curtains. Additionally, they offer a reliable solution for dewatering applications, ensuring efficient desludging of wastewater ponds. Prefabricated vertical drains made from composite geotextiles are also available for dewatering purposes.

❖Cost-Effective

Geocomposites reduce the amount of aggregate needed in construction and speed up installation, so they are a very economical solution.

❖Quick And Easy Installation

Installation of geocomposites do not require heavy equipment. The installation can be done in a wide variety of weather conditions.

❖Very Rigid

Our geocomposite reinforcements are very rigid, which is important in terms of the lateral support that supports the structure and thus the formation of a reinforcing effect. Thanks to their load distributing properties, geogrids reduce uneven settlements and road rutting, even in extremely unfavorable soil conditions.

❖Good Durability

Geocomposite reinforcements have a lifespan of up to 120 years in natural soil and do not require special maintenance, when properly designed, installed and maintained.

❖Environmentally Friendly

The materials of geocomposites do not dissolve dangerous substances into the environment. The carbon footprint of reinforcements is smaller compared to traditional methods. In addition, it reduces emissions caused by transportation and the need for maintenance and repair of surfaces in the future.

Overall, composite geotextiles are a versatile and reliable solution for various geotechnical applications. Their combination of different materials enables them to provide enhanced performance compared to traditional methods. The use of composite geotextiles not only improves functionality but also offers cost-effective solutions for projects that require drainage, reinforcement, or pollution control.

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

![]() Packing of Composite Geomembrane Liner

Packing of Composite Geomembrane Liner

|

|

|

Packaged by the Woven bag |

Width: 2-8m, Lenght: 50-100m/Roll |

Width 1.0-8.0 meters; Length 50.0 – 200 meters

*We can manufacture the products in accordance with custom specifications or specific design criteria.

Please Contact us to Get More Details and Composite Geomembrane Liner Solutions, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

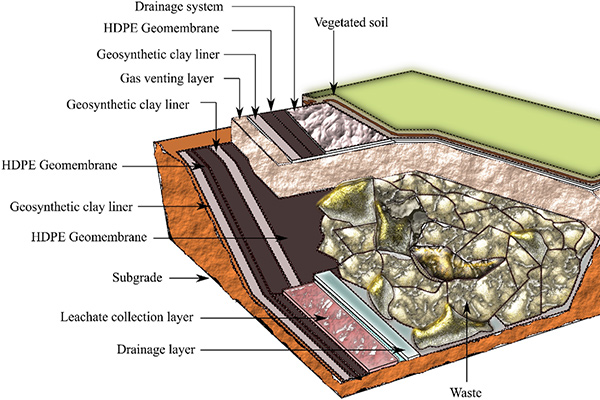

Geosynthetics are manufactured synthetic materials (i.e., made from polymers or hydrocarbon chains) that are used for a wide range of engineering applications. Seven categories of geosynthetic materials are manufactured: geocomposites, geogrids, geomembranes, geonets, geopipes, geotextiles, and geosynthetic clay liners. The geocomposite consists of a combination of one or more geosynthetics, specifically a geogrid, a geotextile, a geomembrane, and/or a geonet, with another material. Geotextiles are used primarily for applications requiring separation, filtration, reinforcement, and drainage. Geogrids are used as reinforcement to improve the strength of soil or other materials. Geonets are relatively thin, planar geosynthetics used for drainage applications, whereas geopipes are buried plastic pipes used for drainage. Geomembranes and geosynthetic clay liners are thin (≤ 10 mm), relatively impervious geosynthetics that are used as barriers in containment applications for waste disposal and in situ remediation. Geosynthetics have gained widespread use only since about 1990, but their use in geoenvironmental engineering applications involving liquid and waste containment has grown substantially in the last decade. A detailed description of the properties, characteristics, and uses of each of these types of geosynthetic can be found in our wibsite.

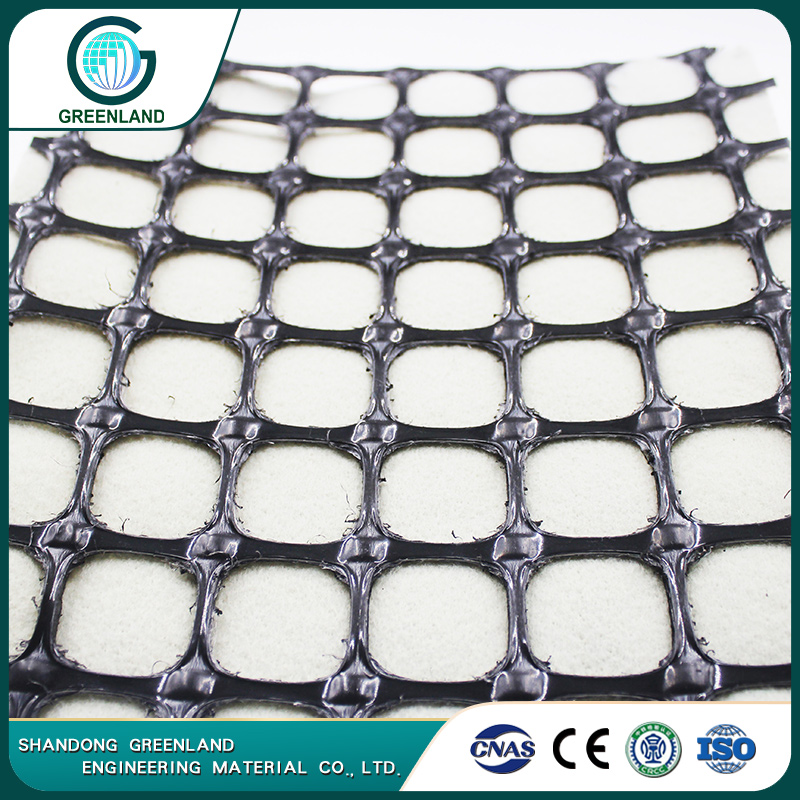

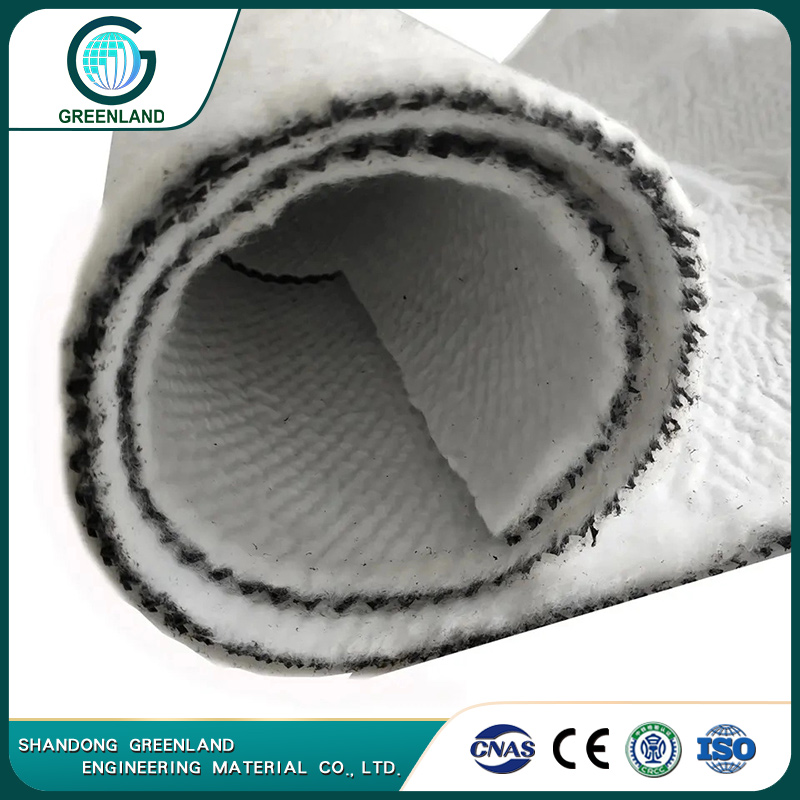

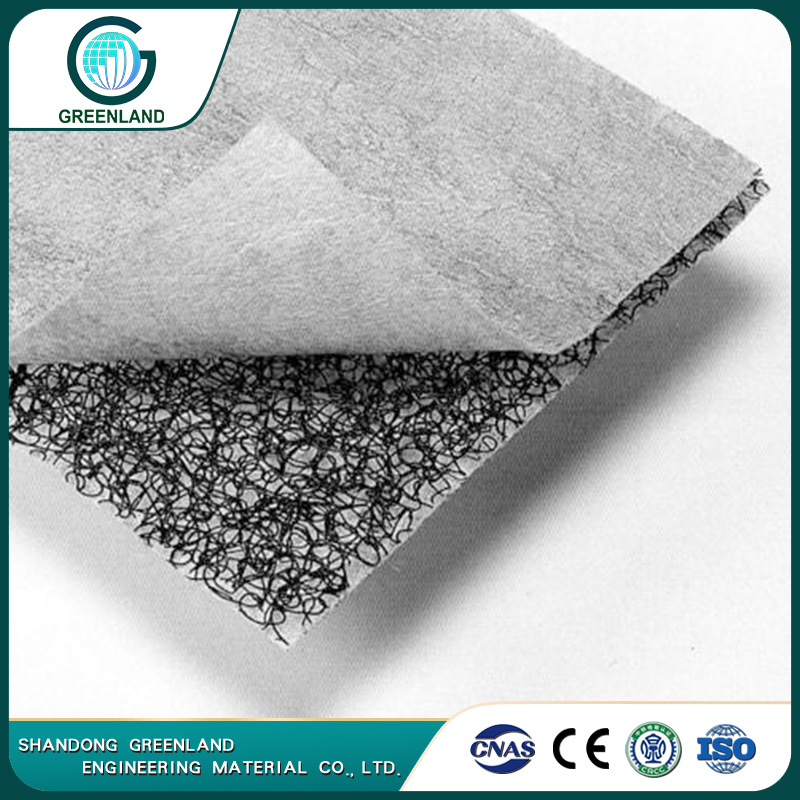

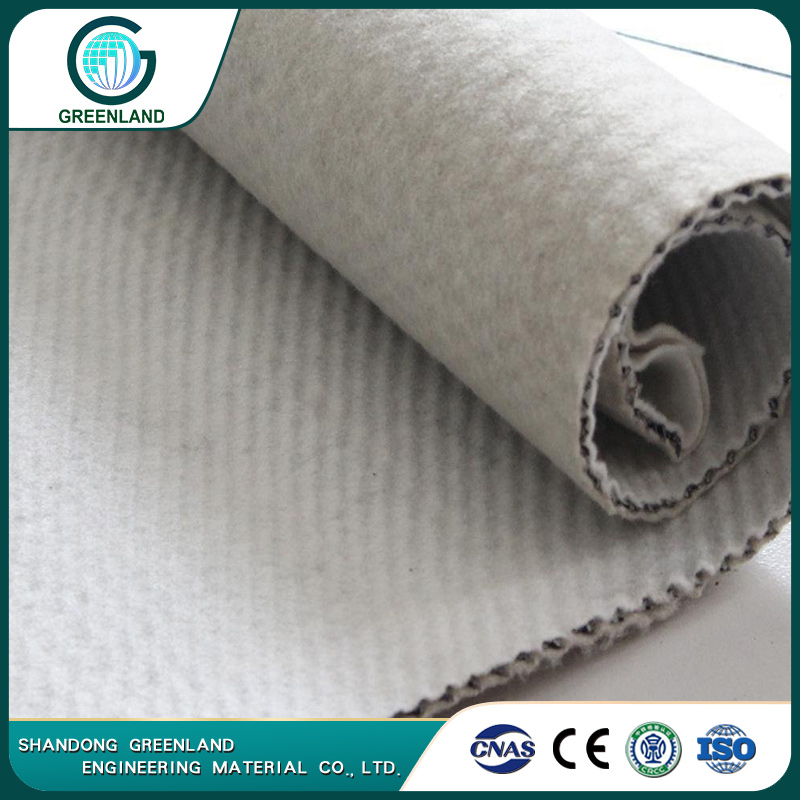

❖Geotextile-geonet composites

When a geotextile is used on one or both sides of a geonet, the separation and filtration functions are always satisfied, but the drainage function is vastly improved in comparison to geotextiles by themselves. Such geocomposites are regularly used in intercepting and conveying leachate in landfill liner and cover systems and for conducting vapor or water beneath pond liners of various types. These drainage geocomposites also make effective drains to intercept water in a capillary zone where frost heave or salt migration is a problem.[citation needed] In all cases, the liquid enters through the geotextile and then travels horizontally within the geonet to a suitable exit.

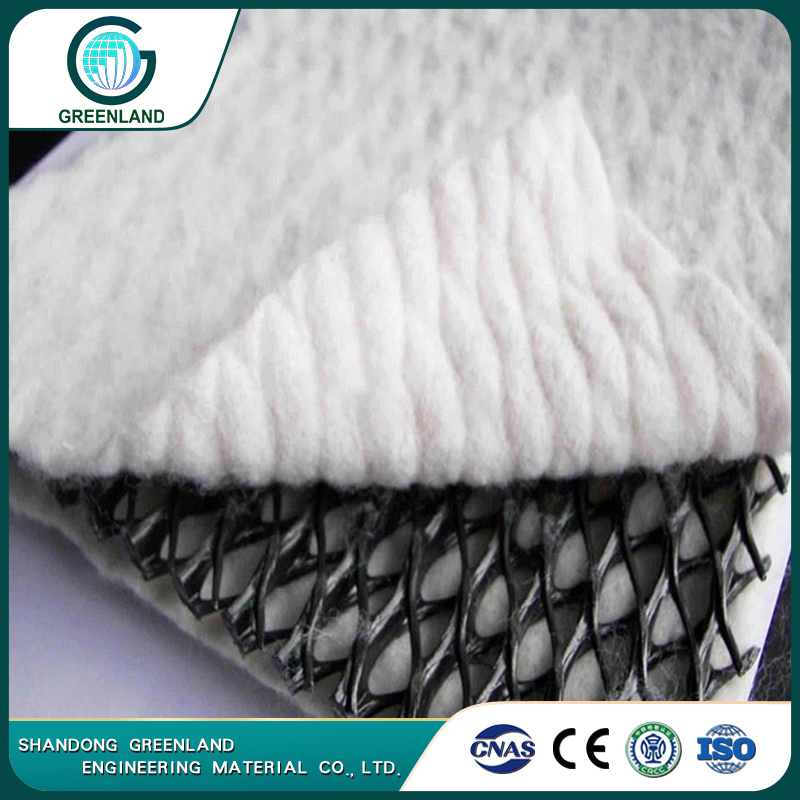

❖Multi-linear drainage composites

A manufactured product composed of a series of parallel single drainage conduits (like perforated mini-pipes) regularly spaced across the width of the product and sandwiched between two or more geosynthetics (more often geotextiles). They are used for liquid drainage or gas collection while providing a separation and filtration function. Such multi-linear drainage composites are not susceptible to creep in compression or geotextile intrusion when confined in the soil, which means that they maintain their flow capacity over time, even under heavy loads.These drainage geocomposites are regularly used in landfill applications for leachate collection layers and cover systems, and in buildings for sub-slab depressurization systems to collect toxic gases (Radon, VOCs, etc.) and prevent their migration into the building.

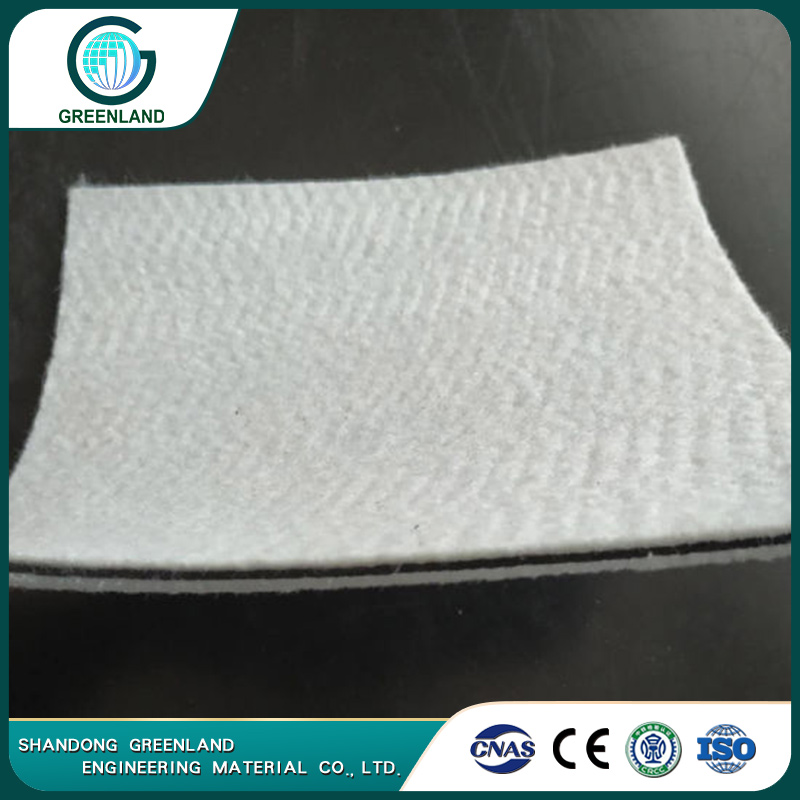

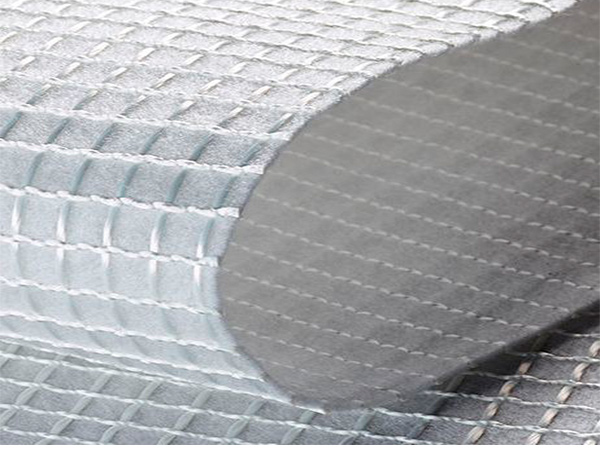

❖Geotextile-geomembrane composites

Geotextiles can be laminated on one or both sides of a geomembrane for a number of purposes. The geotextiles provide increased resistance to puncture, tear propagation, and friction related to sliding, as well as providing tensile strength in and of themselves. Geotextiles are of heavy and are of the nonwoven, needle-punched variety. In such cases the geotextile component acts as a drainage medium, since it can conduct water, leachate or gases away from direct contact with the geomembrane.

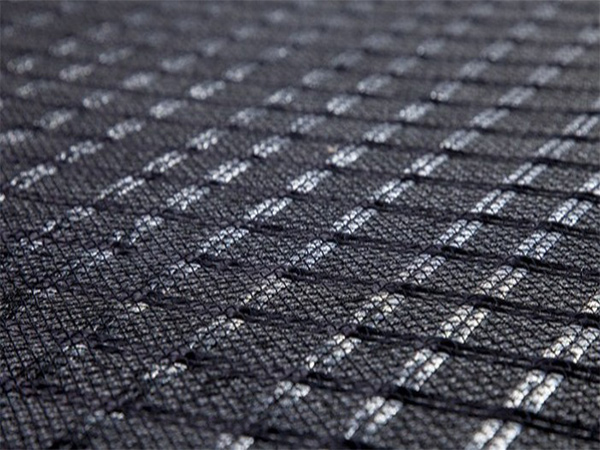

❖Geomembrane-geogrid composites

Since some types of geomembranes and geogrids can be made from the same material (e.g., high-density polyethylene), they can be bonded together to form an impervious membrane barrier with enhanced strength and friction capabilities.

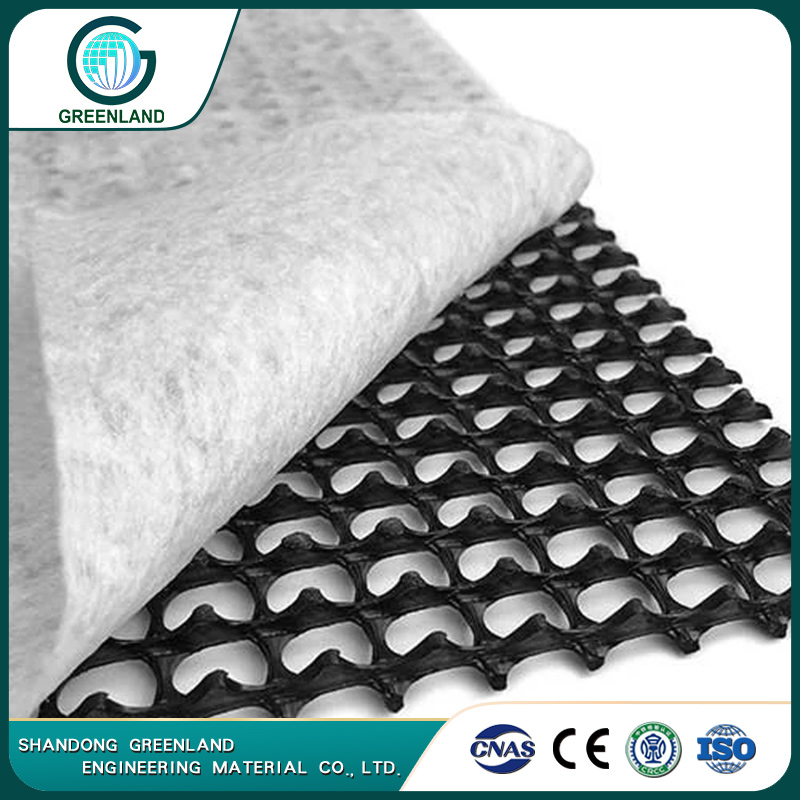

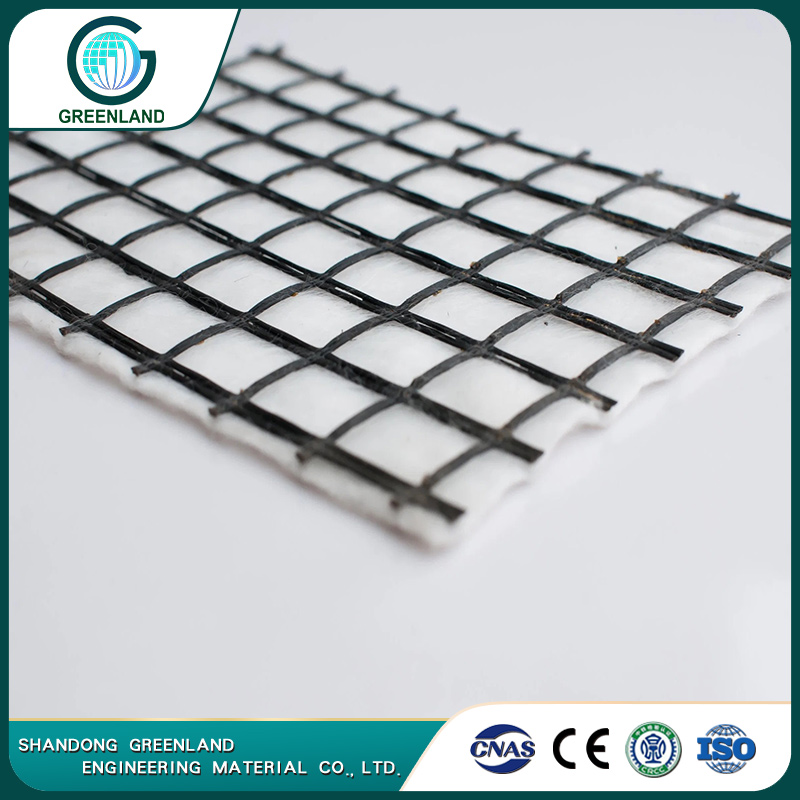

❖Geotextile-geogrid composites

A needle-punched nonwoven geotextile bonded to a geogrid provides in-plane drainage while the geogrid provides tensile reinforcement. Such geotextile-geogrid composites are used for internal drainage of low-permeability backfill soils for reinforced walls and slopes. The synergistic properties of each component enhance the characteristics of the final product.

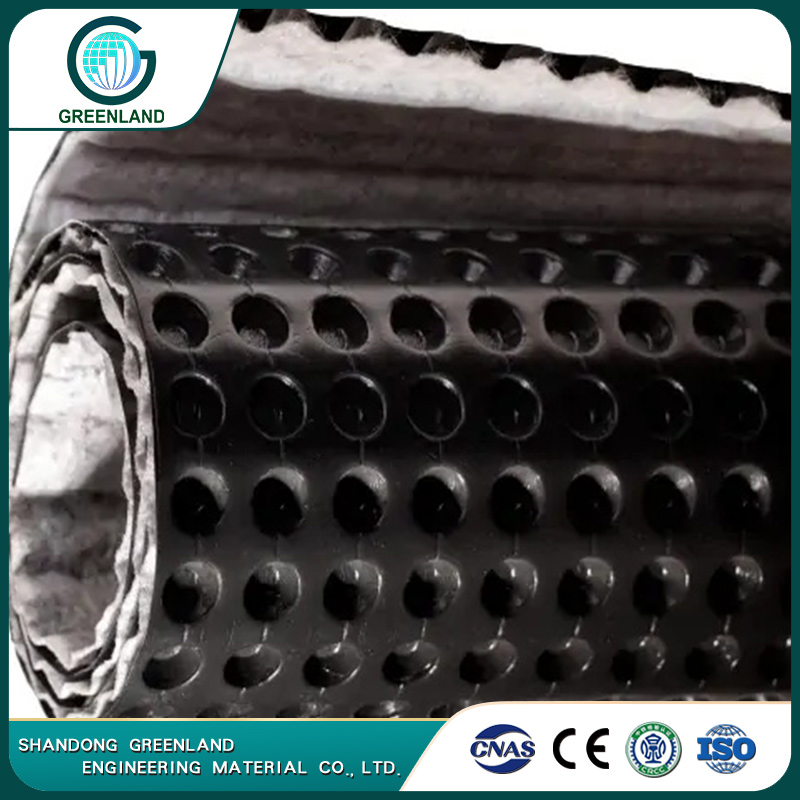

❖Geotextile-polymer core composites

A core in the form of a quasi-rigid plastic sheet, it can be extruded or deformed in such a way as to allow very large quantities of liquid to flow within its structure; it thus acts as a drainage core. The core must be protected by a geotextile, acting as a filter and separator, on one or both sides. Various systems are available, each focused on a particular application.

As known; Geocomposites generally consist of various combinations of geosynthetic materials. So the specifications are customized according to the different geosynthetic material, please CONTACT US for more information

☎Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Applications of Composite Geomembrane

Applications of Composite Geomembrane

Geocomposites formed in this way have application areas in many areas.

In the construction of foundation drainage system in airport projects

In railway new line construction applications

In high-speed railway construction applications

In applications to be made on weak ground on highways

In the filling works of highway projects,

In ground pile applications,

In container storage areas,

It is used in the foundations of ports and industrial structures.

|

|

|

Geocomposites for Road Construction |

Composite Geomembrane Liner Liners for Dam |

|

|

|

Geocomposites for Road Construction |

Geocomposites for Environmental Protection |

|

|

|

Geocomposite for Railway |

Composite Geomembrane Liner for Agriculture And Farming Pond |

Please Contact us to Get More Geocomposites Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Geocomposites

-

- Below are the detailed information of Geocomposites for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST of Data Sheet now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- Woven Geotextile Composite Geomembrane

DownLoad

- Short Fiber Geotextile Composite Geomembrane

DownLoad

- Filament Geotextile Composite Geomembrane

DownLoad - Composite High Efficiency Suction And Drainage Geomembrane

DownLoad

Documents Download of Geocomposites

Documents Download of Geocomposites

Other CUSTOMIZED Geocompositeshave not been shown on above chart, please CONTACT US for more information

Please Contact us to Get More Geocomposites Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.