Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

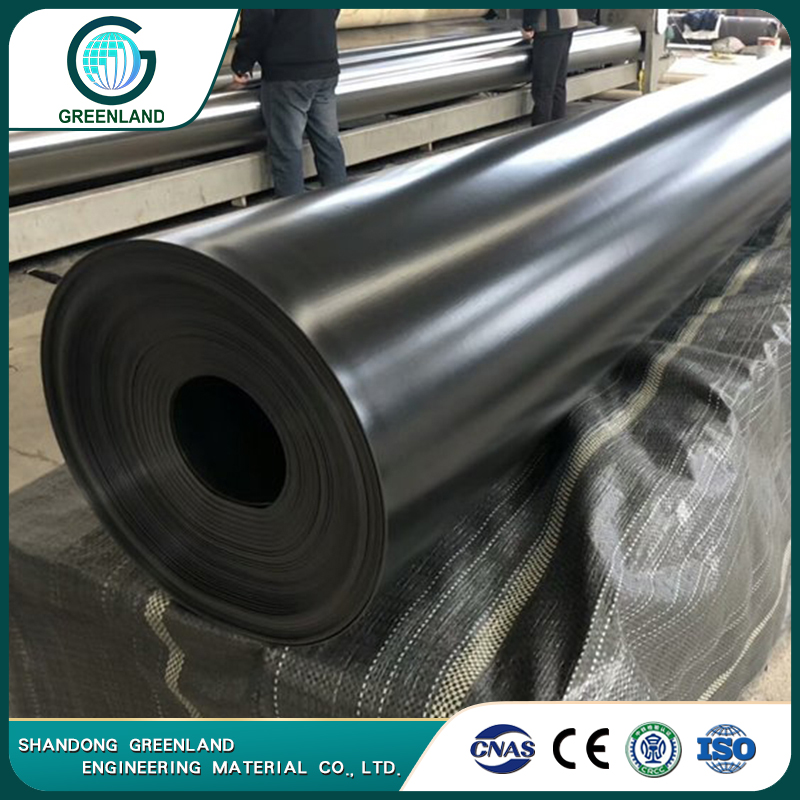

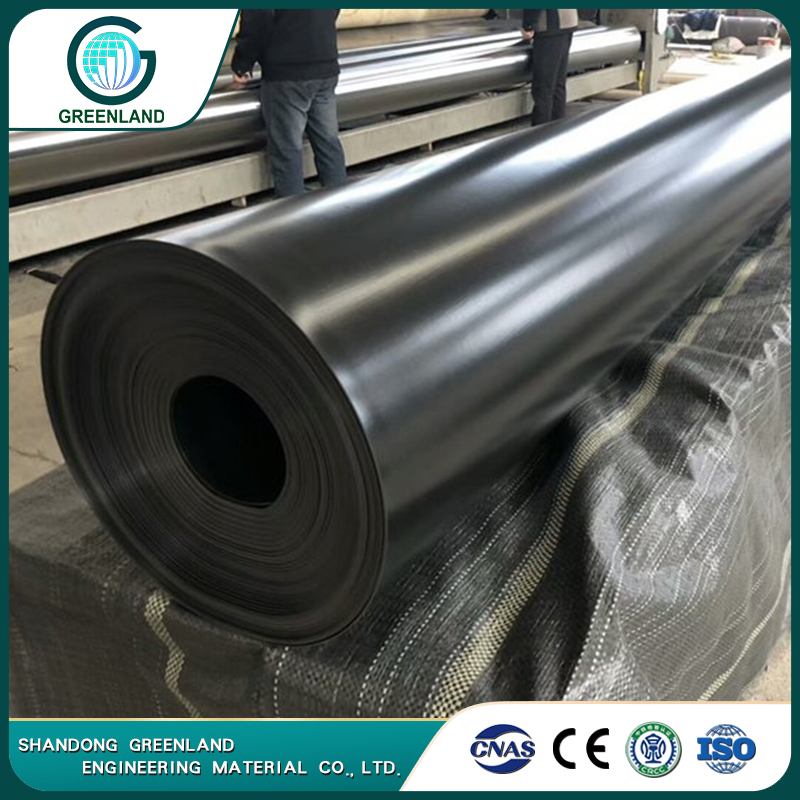

Geomembrane Liner

-

- 1.Thickness: 0.2-4.0mm(20 mils-120 mils)

- 2.Width: Max. 8M

- 3.Raw Material: HDPE, MDPE, LDPE, LLDPE, ECB, EPDM, BGM, EVA, PP, GCLS, GSPE, EPDM…

- 4.Standard: ASTM, GRI, ISO, GH-1, GB/T17643

- 5.Delivery: Stock for regular item, 5-10 Days for Production

- 6.Packing: 50-100m length/roll, Customized

- 7.MOQ: Trial order is acceptable

- 8.Free Sample Available

Geomembranes are commonly used to control seepage from water canals. There are many types of geomembranes available for this application including PVC, HDPE, LDPE, LDPE, LLDPE, MDPE, ECB, EVB, EVA, CSPE, and EPDM geomembranes.

Geomembranes have been used as water canal liners to control seepage since the 1950’s and are an effective alternative to more traditional lining methods, such as concrete and compacted soil.

Quick Details of Geomembrane Liner

Quick Details of Geomembrane Liner

| Products details information | |

| Product name | Geomembrane Liner |

| Brand | Greenland (OEM is available) |

| Thickness | 0.2-4.0mm(20 mils-120 mils) |

| Raw material | HDPE, LDPE, LLDPE, EVA, ECB, PVC, PP, GCLS, GSPE, EPDM... |

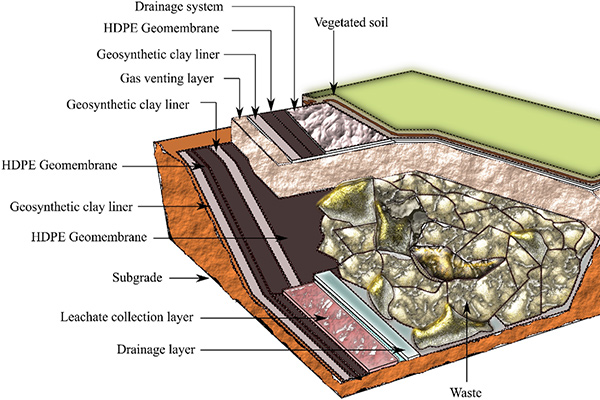

| Application | Anti-seepage projects such as domestic waste landfill anti-seepage, solid waste landfill anti-seepage, sewage treatment plant anti-seepage, artificial lake anti-seepage, tailings treatment and other anti-seepage projects. |

| Color | Black, White, other colors |

| Standards | ASTM, GRI, ISO, GH-1, GB/T17643, ects |

| Welding Tools | Hot air welding gun, geomembrane welding machine, etc |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

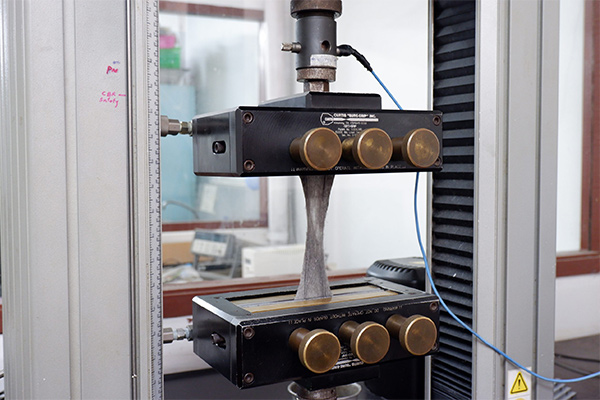

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

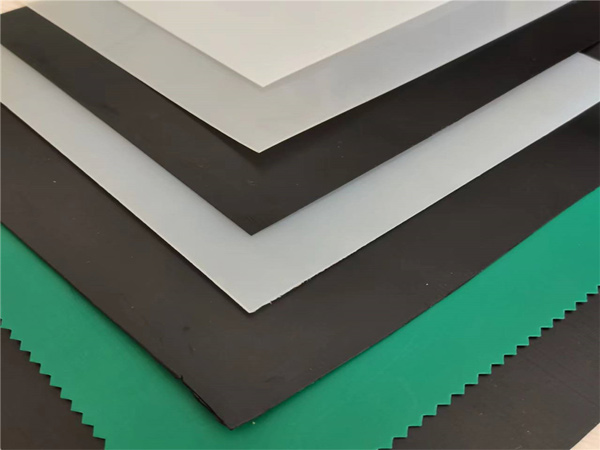

Different Materials for Geomembrans (HDPE, LDPE, LLDPE, EVA, ECB, PVC, PP, GCLS, GSPE, EPDM...)

Different Materials for Geomembrans (HDPE, LDPE, LLDPE, EVA, ECB, PVC, PP, GCLS, GSPE, EPDM...)

Traditionally, PVC geomembranes have been the geomembrane used for canal-lining projects. However, recently polyethylene (PE) based geomembranes (HDPE, LDPE, CSPE and VLDPE) as well as several other types of geomembranes (e.g. EDPM and polypropylene) have been used as canal liners.

The Most Commonly Used Type Of Geomembrane

The Most Commonly Used Type Of Geomembrane

| ❖HDPE Geomembranes | ❖PVC Geomembranes | ||

| ❖LLDPE Geomembranes | ❖Polypropylene(PP) Geomembranes | ||

| ❖EPDM Geomembranes | ❖TRP Geomembranes | ||

| ❖ECB Geomembranes | ❖EVA Geomembranes |

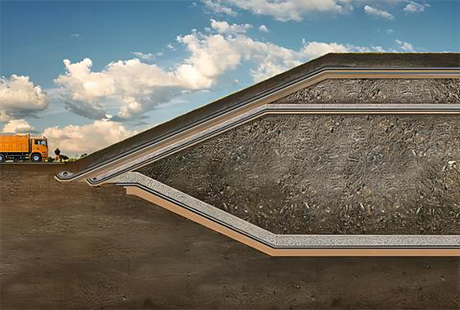

All geomembranes are susceptible to damage from sun, wind, wave action, vegetation roots, and animal traffic, and thus must be protected. The most traditional method of protecting a geomembrane is to cover it with compacted soil. Another method is to cover the liner with concrete or shotcrete. The last option is to not protect the geomembrane and leave it exposed. Such exposed geomembranes may require special treatment and consideration to prevent damage.

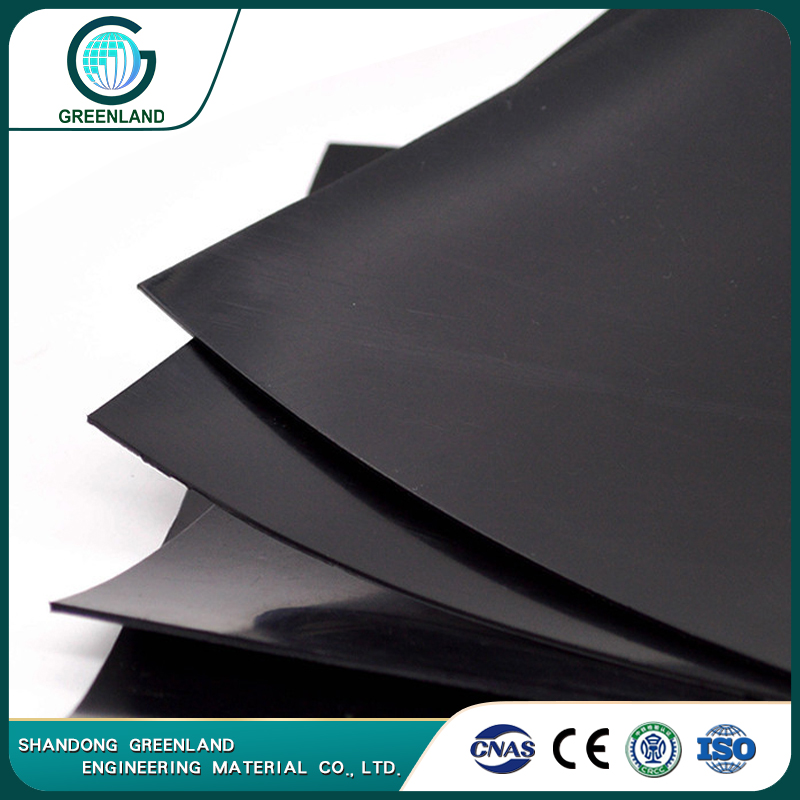

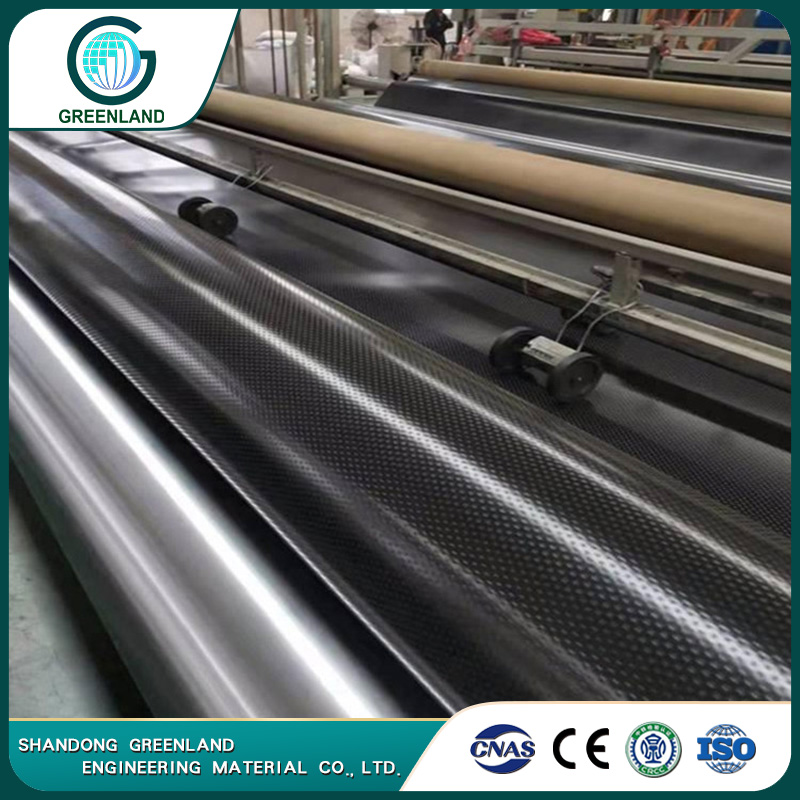

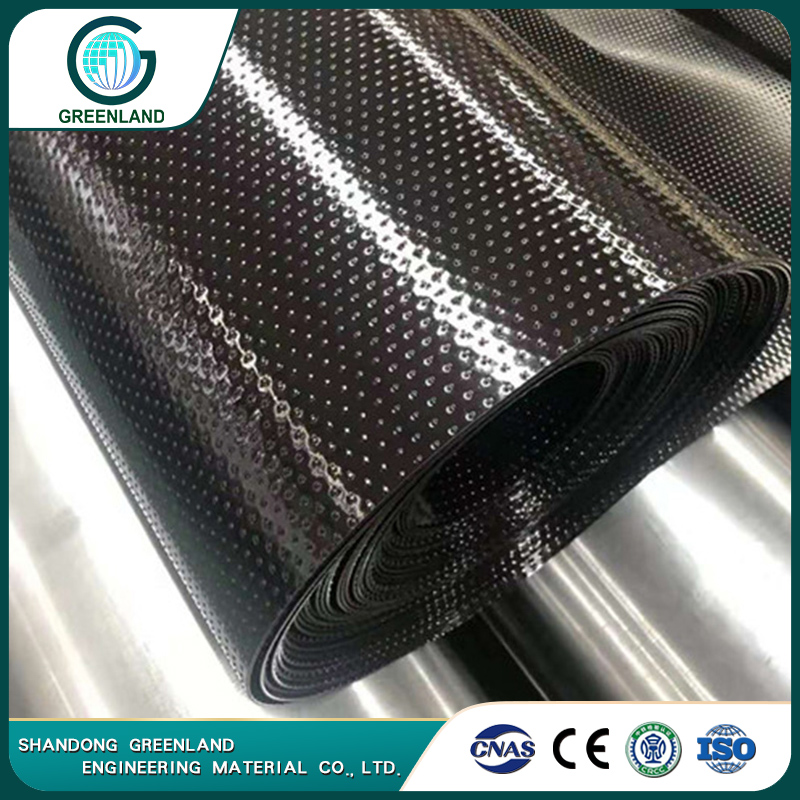

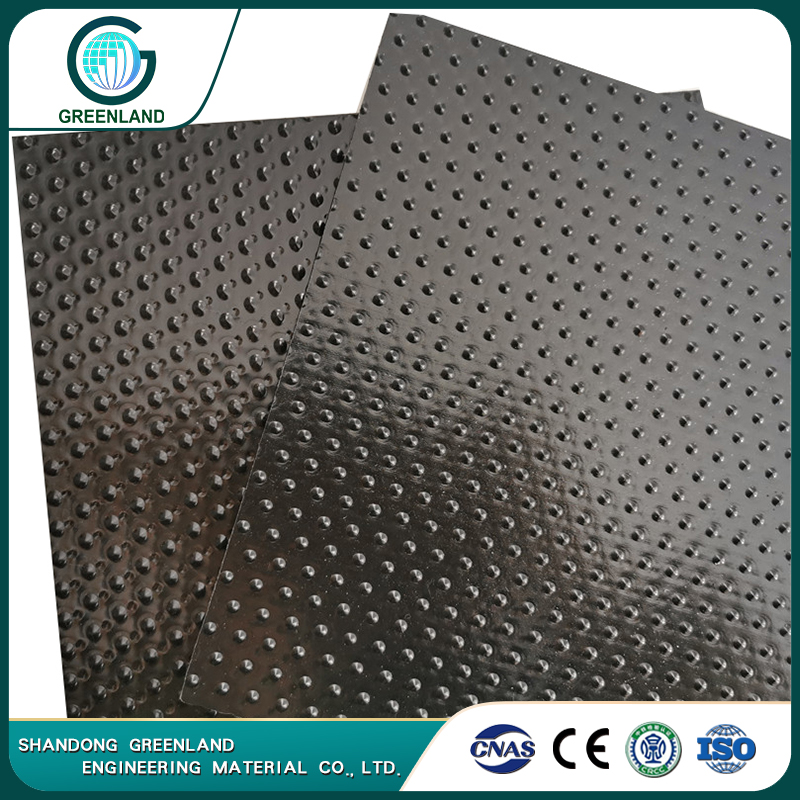

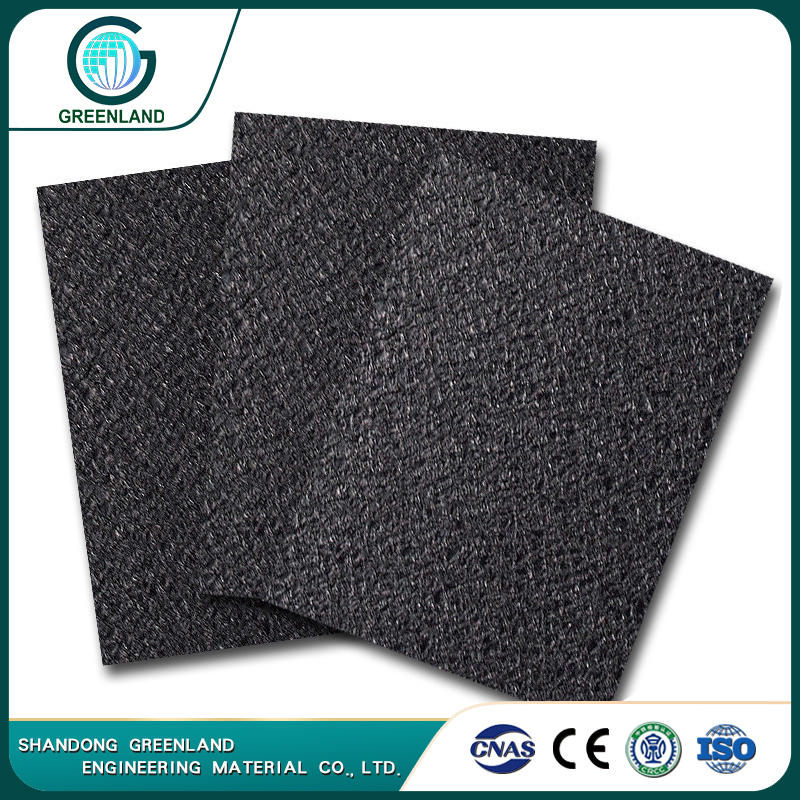

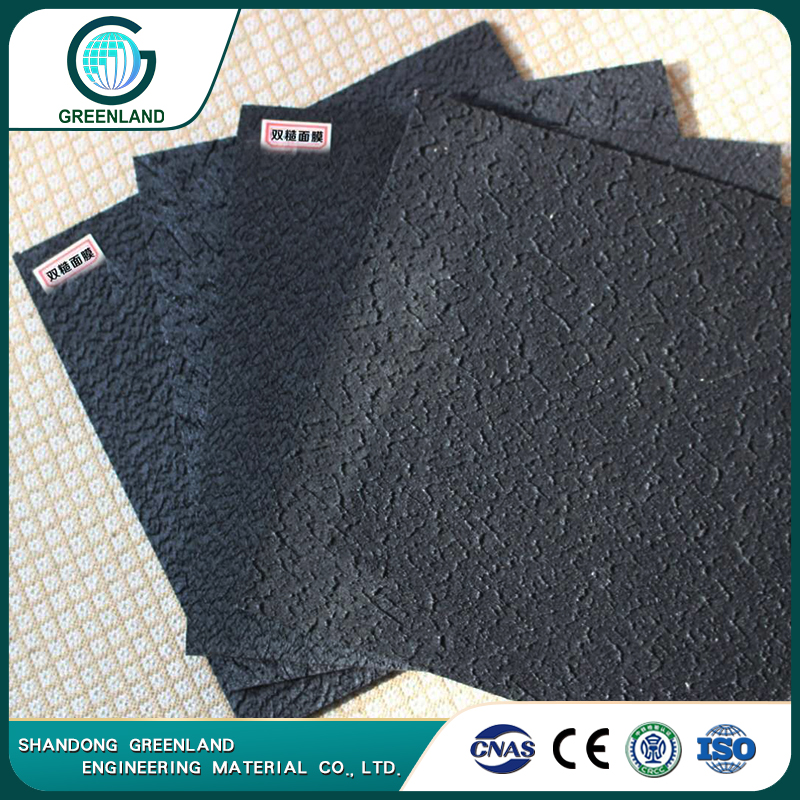

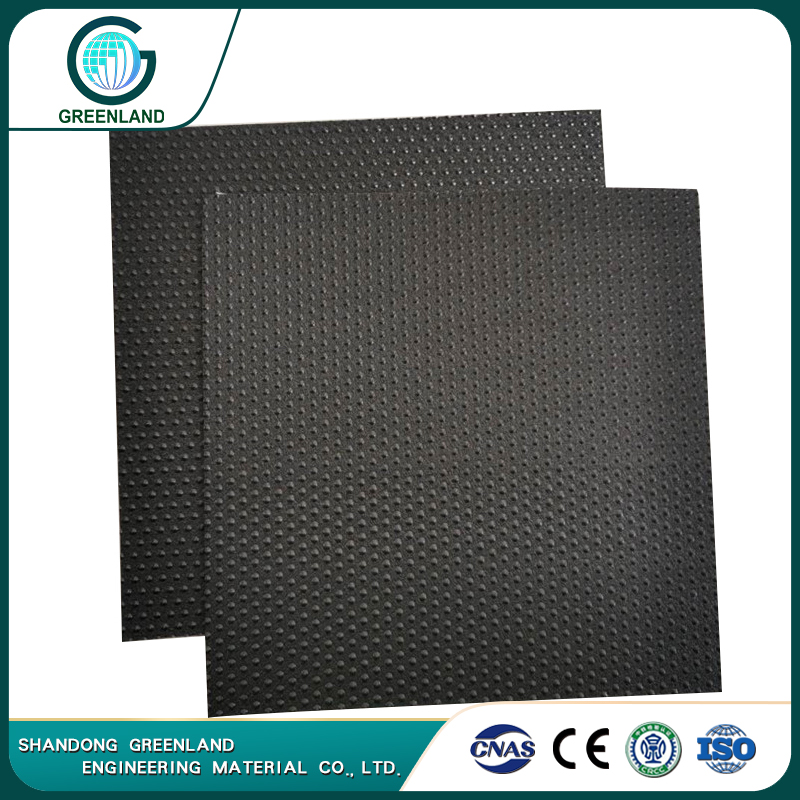

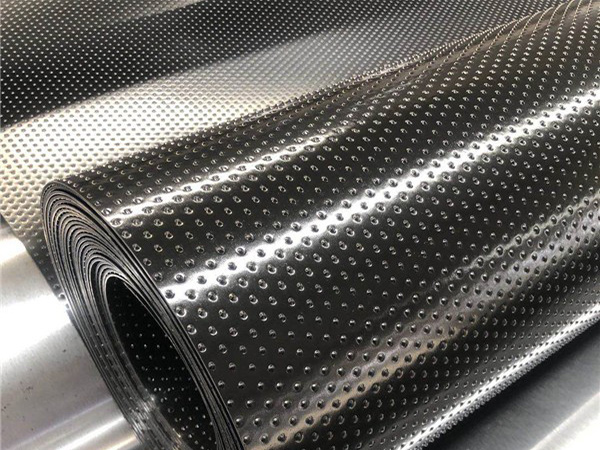

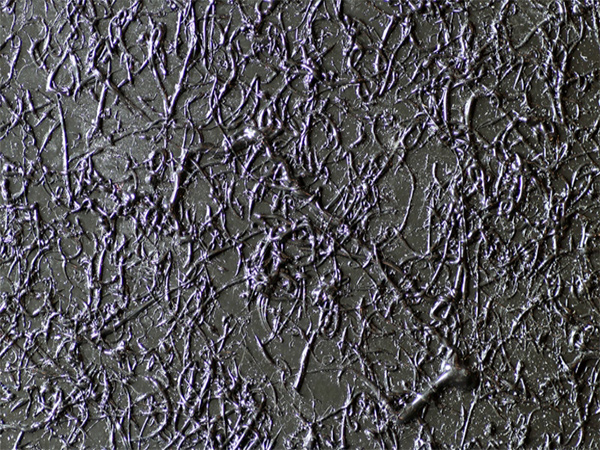

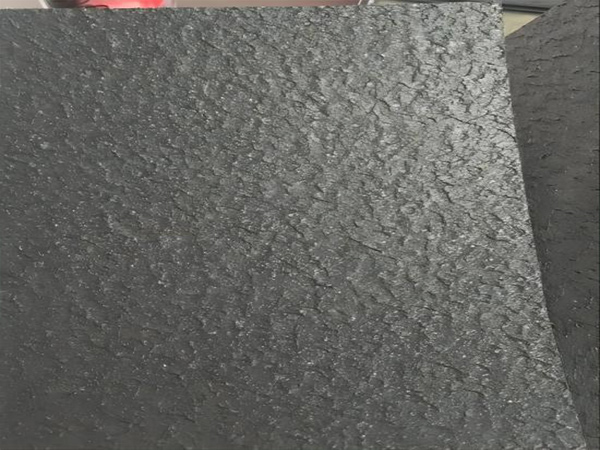

Geomembranes are essentially impermeable polymeric lining materials used as fluid barriers in geotechnical engineering applications. Geomembranes can have a smoother or textured surface. The textured surface provides enhanced friction characteristics which can be important in certain applications.

Different Kinds of Geomembrane

Different Kinds of Geomembrane

|

|

|

| Smooth Geomembranes | Smooth Geomembranes | Smooth Geomembranes in different color |

|

|

|

| Column Points Geomembrane | Spraying Textured Geomembrane | Textured Geomembranes |

❖Please Contact US and Get a Solutions of the Geomembrane Now.

Benefits of Geomembrane

Benefits of Geomembrane

Geomembrane is regularly used for the containment of hazardous liquids that can contaminate the ground or surrounding structures if not correctly contained.

Provide Positive Water Containment

Help Sustain Water Quality

Establish Erosion Control

Reduce Maintenance Cost

Lower Disease Risk

Manage Waste Removal

Prevent The Loss Of Dissolved Oxygen

Increase The Turn-Around Time Between Corps

Improve Work Environment

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

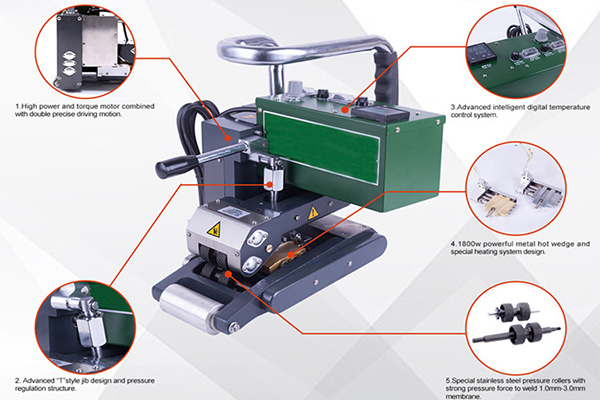

Installation Tools for the Geomembranes Liners Greenland Provide

Installation Tools for the Geomembranes Liners Greenland Provide

|

|

|

|

Gromembranes Welding Machine |

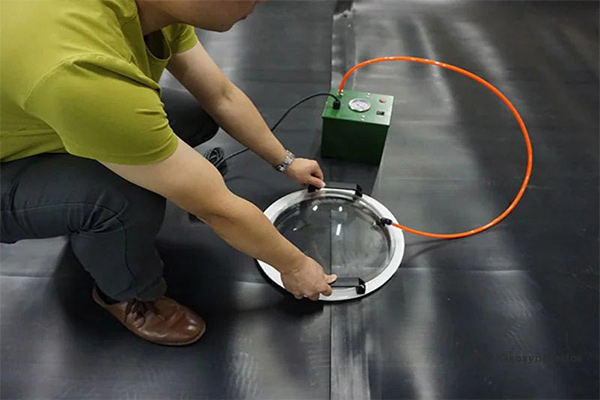

Air Pressure Testing Equipment |

Geomembrane Liner Leakage Detectors |

For the welding quality control of geomembrane, we usually use geomembrane liner leakage detectors, vacuum boxes, air pressure testing equipment and other equipment to perform quality control on the surface and welds of the geomembrane.

Packing of HDPE/LDPE/LLDPE Geomembranes Liners

Packing of HDPE/LDPE/LLDPE Geomembranes Liners

|

|

|

Packaged by the Woven bag |

Width: 2-8m, Lenght: 50-100m/Roll |

Please Contact us to Get More Details and Geomembrane Solutions, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Specifications of Different Standard Geomembranes

Specifications of Different Standard Geomembranes

1. HDPE Smooth Surface Geomembrane (GB/T17643-2011 standard)

| Number | Item | Indicators | ||||||||

| Thickness(mm) | 0.3 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |

| 1 | Density(g/m³) | ≥0.940 | ||||||||

| 2 | Longitudinal and transverse tensile yield strength( N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

| 3 | Longitudinal and transverse tensile fracture strength(N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

| 4 | Longitudinal and transverse yield elongation( %) | - | - | ≥11 | ||||||

| 5 | Longitudinal and transverse elongation at break( %) | ≥600 | ||||||||

| 6 | Vertical and horizontal right angle tear load(N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

| 7 | Puncture resistance strength(N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

| 8 | Carbon black content(%) | 2.0~3.0 | ||||||||

| 9 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||||

| 10 | Induction time of atmospheric pressure oxidation(OIT)(min) | ≥60 | ||||||||

| 11 | Low temperature impact embrittlement performance | Pass | ||||||||

| 12 | Water vapor permeability coefficient(g·cm/(cm·s.Pa) | ≤1.0×10-13 | ||||||||

| 13 | Dimensional stability(%) | ±2.0 | ||||||||

| Note: The technical performance indicators for thickness specifications not listed in the table are required to be executed using interpolation method. | ||||||||||

2. Environmentally Friendly HDPE Smooth Surface Geomembrane (GB/T17643-2011 GH-2S standard)

| Number | Item | Indicators | ||||||

| 1 | Thickness(mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 |

| 2 | Density(g/cm³) | ≥0.940 | ||||||

| 3 | Tensile yield strength (woven, transverse)N /mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (woven, transverse) N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse) % | ≥700 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

| 8 | Puncture resistance strength(N) | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 |

| 9 | Tensile load stress cracking (notch constant load tensile method) h | ≥300 | ||||||

| 10 | Carbon black content(%) | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | Atmospheric pressure oxidation induction time (OIT) (min) | Induction time of atmospheric pressure oxidation ≥100 | ||||||

| Induction time of high-pressure oxidation ≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

3. HDPE Smooth Surface Geomembrane for Landfill Sites-Technical Specifications CJ/T 234-2006 (equivalent to US GRI-GM13 standard)

| Number | Item | Indicators | ||||||

| 1 | Thickness(mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 |

| 2 | Density(g/cm³) | ≥0.939 | ||||||

| 3 | Tensile yield strength (woven, transverse)N /mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (woven, transverse) N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse) % | ≥700 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥156 | ≥187 | ≥249 | ≥311 | ≥374 |

| 8 | Puncture resistance strength(N) | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 |

| 9 | Resistance to environmental stress cracking | ≥300 | ||||||

| 10 | Carbon black content(%) | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | Atmospheric pressure oxidation induction time (OIT) (min) | Induction time of atmospheric pressure oxidation ≥100 | ||||||

| Induction time of high-pressure oxidation ≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

4. HDPE Rough Surface Geomembrane/Column Point Textured Geomembrane<GB/T17643-2011 GH-2T1 And GH-2T2 Technical Specifications>

| Number | Item | Indicators | ||||||

| Thickness (mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |

| 1 | Density (g/m³) | ≥0.940 | ||||||

| 2 | Roughness height (mm) | ≥0.25 | ||||||

| 3 | Tensile yield strength (longitudinal and transverse) N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (longitudinal and transverse) N/mm | ≥8 | ≥10 | ≥13 | ≥16 | ≥21 | ≥26 | ≥32 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse)% | ≥100 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

| 8 | Puncture resistance strength N | ≥200 | ≥270 | ≥335 | ≥400 | ≥535 | ≥670 | ≥800 |

| 9 | Tensile load stress cracking (notch constant load tensile method) h | ≥300 | ||||||

| 10 | Carbon black content % | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | oxidation induction time(OIT)(min) | Induction time of atmospheric pressure oxidation≥100 | ||||||

| Induction time of high-pressure oxidation≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

| Note: The technical performance indicators for thickness specifications not listed in the table are required to be executed using interpolation method. | ||||||||

❖The Other Specifications and Standards of the Geomembrane are not listed here, please contact to get it now.

Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Applications of Geomembrane Liners

Applications of Geomembrane Liners

Frozen, pooling, flowing, wastewater, and standing liquids can be hazardous if not properly managed. Hence, geomembranes are used to prevent the loss of material.

Geomembranes liners for various waste conveyance canals

Geomembranes liners used in tunnels and pipelines

Geomembranes liners for the agriculture industry

Geomembranes liners for potable or reserve water (for example, safe shutdown of nuclear facilities)

To contain and transport potable water and other liquids in the ocean

Geomembranes liners for the agriculture industry

Geomembranes liners used for fish pond liners

Geomembranes liners used for highways to prevent pollution from deicing salts

Geomembranes liners for primary, secondary, or/and tertiary waste piles and solid-waste landfills

Adjacent and beneath highways to capture hazardous liquid spills

Geomembranes liners for sewage sludge, radioactive or hazardous waste liquid

Geomembranes liners for emergency spillways

To contain and transport liquids in trucks

|

|

|

Geomembranes for Construction of Artificial Lake |

Geomembrane Liners for Dam |

|

|

|

Geomembranes for Isolation of Sewage& Landfill |

Geomembranes for Aquaculture |

|

|

|

Geomembranes liners for Mining |

Geomembrane Liners for Agriculture And Farming Pond |

Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

-

- Below are the detailed information of Geomembrane Liners for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST of Geomembrane Liners now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- HDPE Smooth Surface Geomembrane

DownLoad - PVC Geomembrane

DownLoad - LLDPE Geomembrane

DownLoad - HDPE Single Surface Geomembrane

DownLoad - HDPE Column Point Textured Geomembrane

DownLoad

Documents Download of Geomembrane Liners

Documents Download of Geomembrane Liners

Other CUSTOMIZED Geomembrane Liners have not been shown on above chart, please CONTACT US for more information

Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.