Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

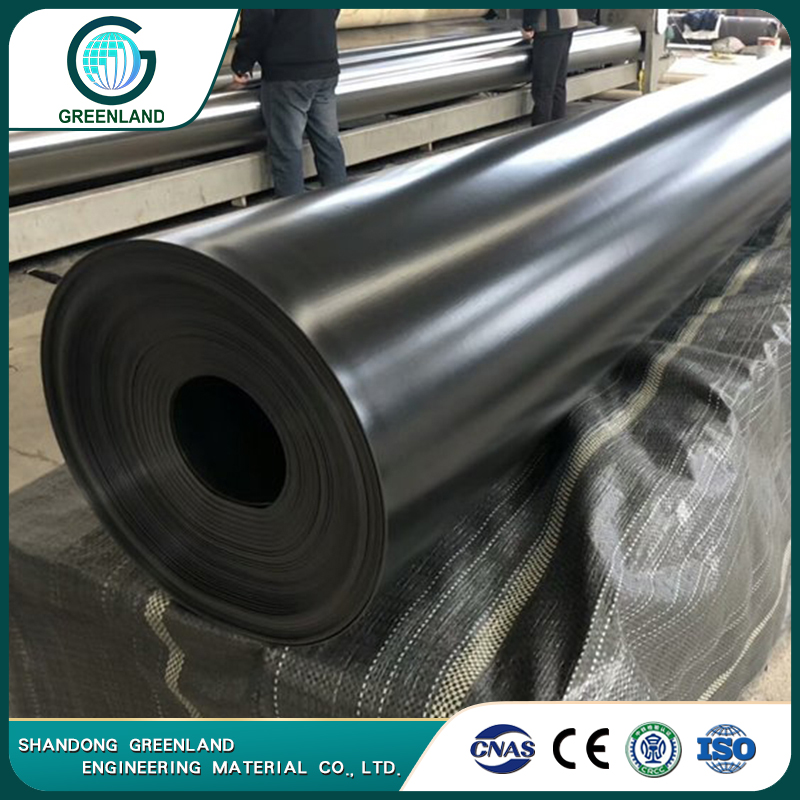

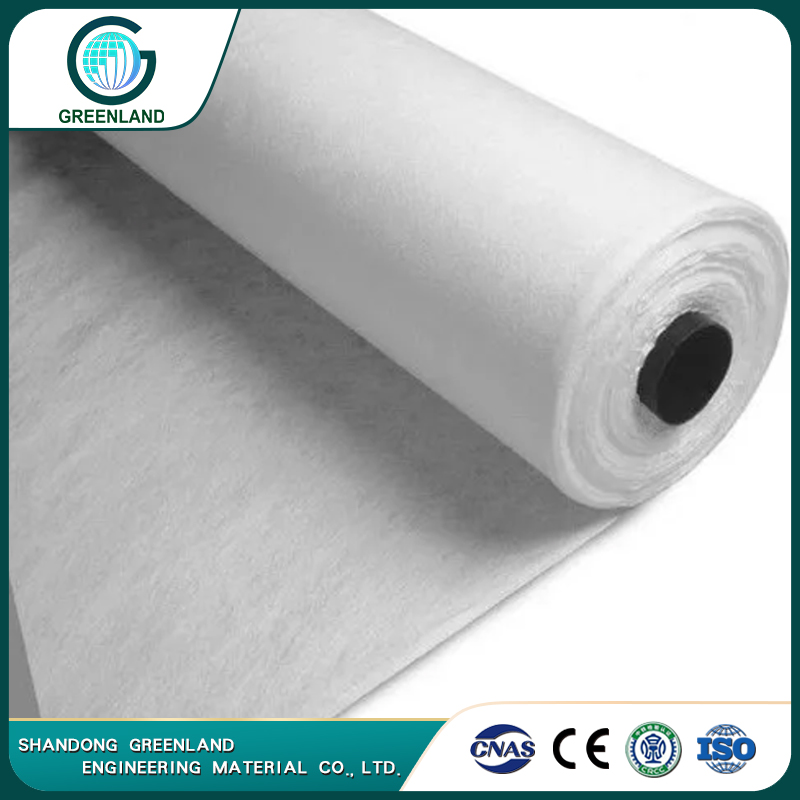

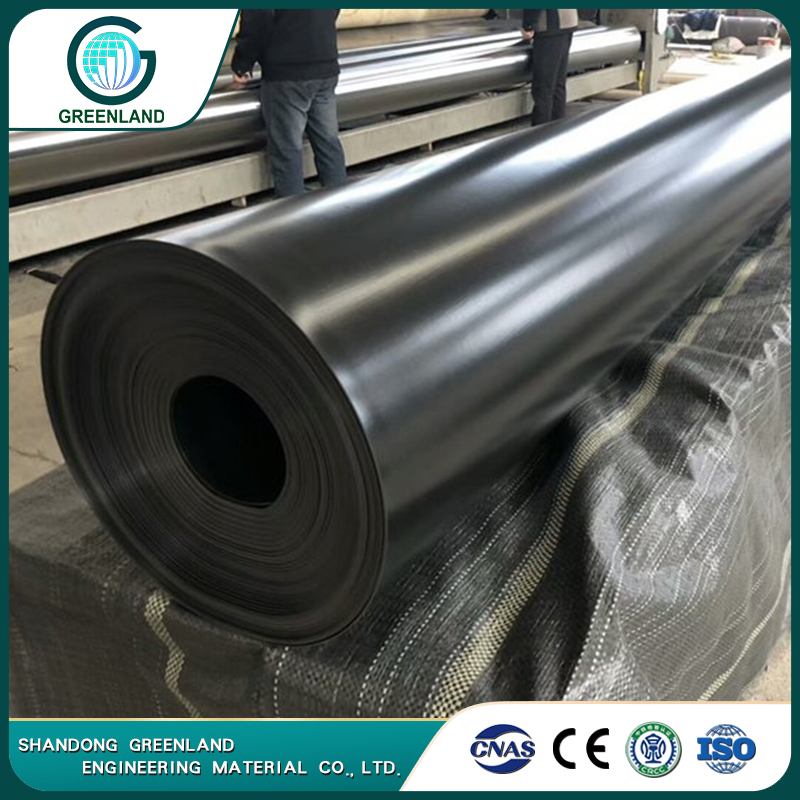

HDPE/LDPE/LLDPE Geomembranes Liners

-

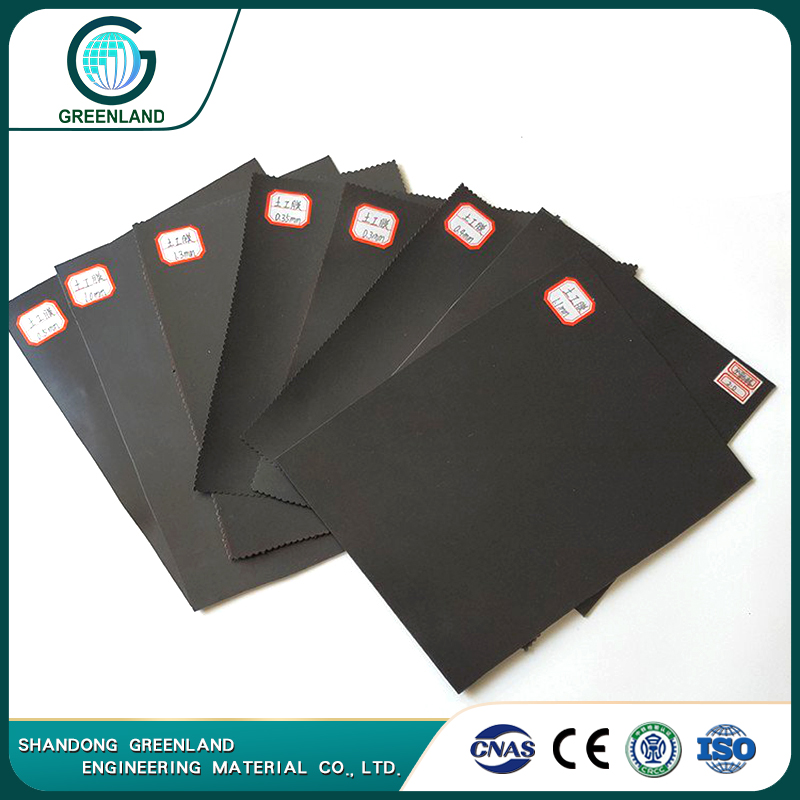

- 1.Thickness: 0.2-4.0mm(20 mils-160 mils)

- 2.Width: Max. 8M

- 3.Raw Material: HDPE, MDPE, LDPE, LLDPE…

- 4.Standard: ASTM, GRI, ISO, GH-1, GB/T17643

- 5.Delivery: Stock for regular item, 5-10 Days for Production

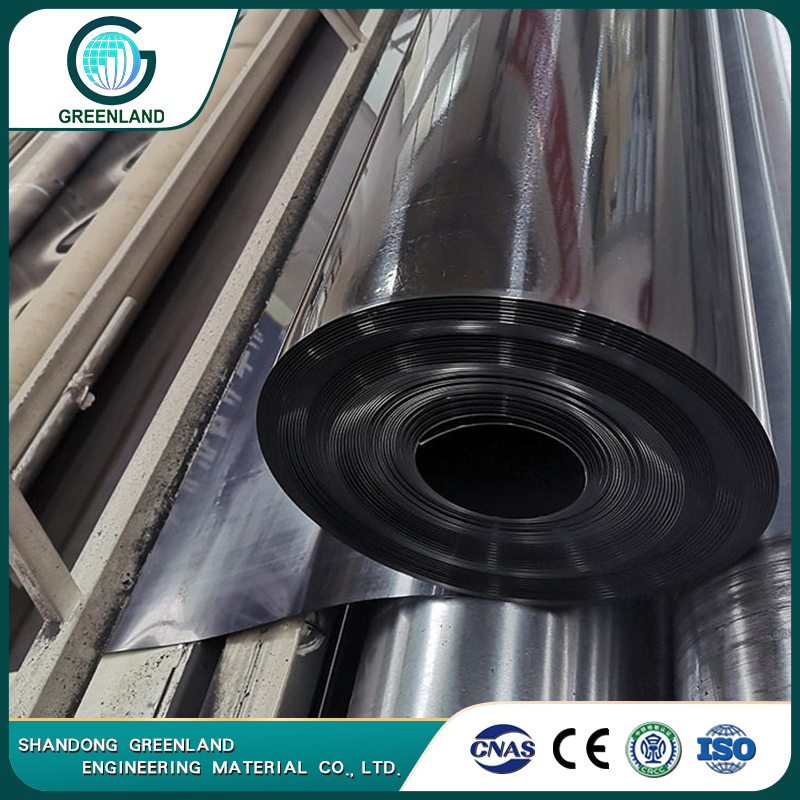

- 6.Packing: 50-100m length/roll, Customized

- 7.MOQ: Trial order is acceptable

- 8.Free Sample Available

HDPE liners (Geomembranes) are produced from High-Density Polyethylene resin. The manufacturing process involves film-blowing, adding carbon black, antioxidant, anti-aging, and UV-resistance components to form a sheet.

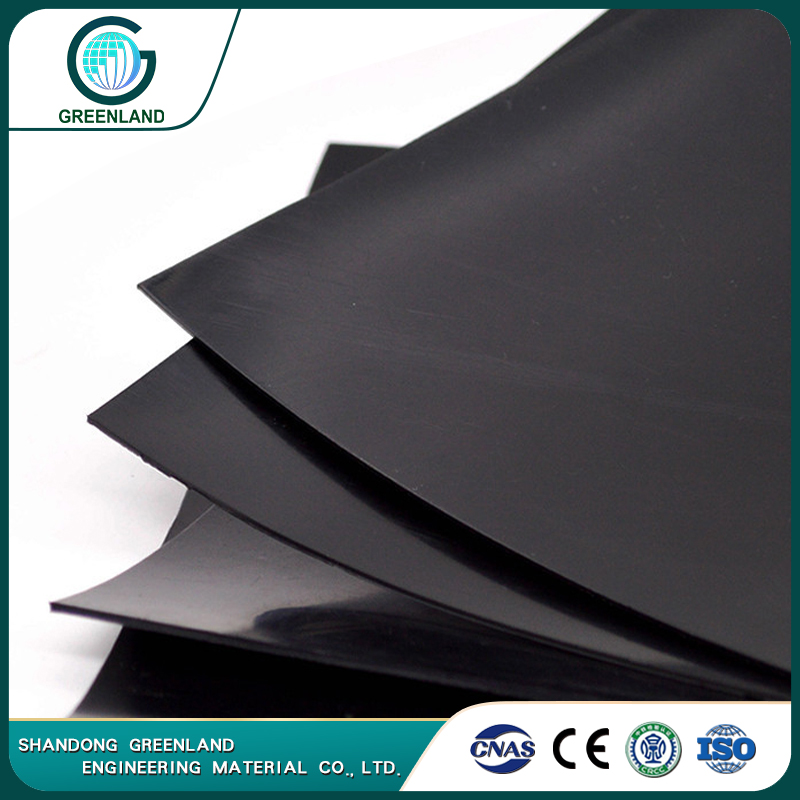

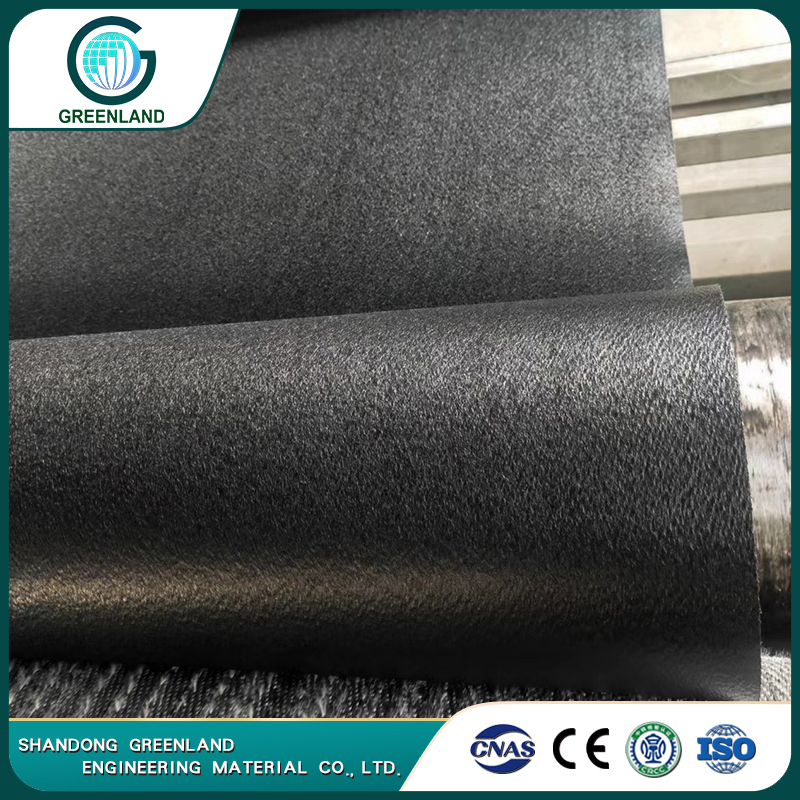

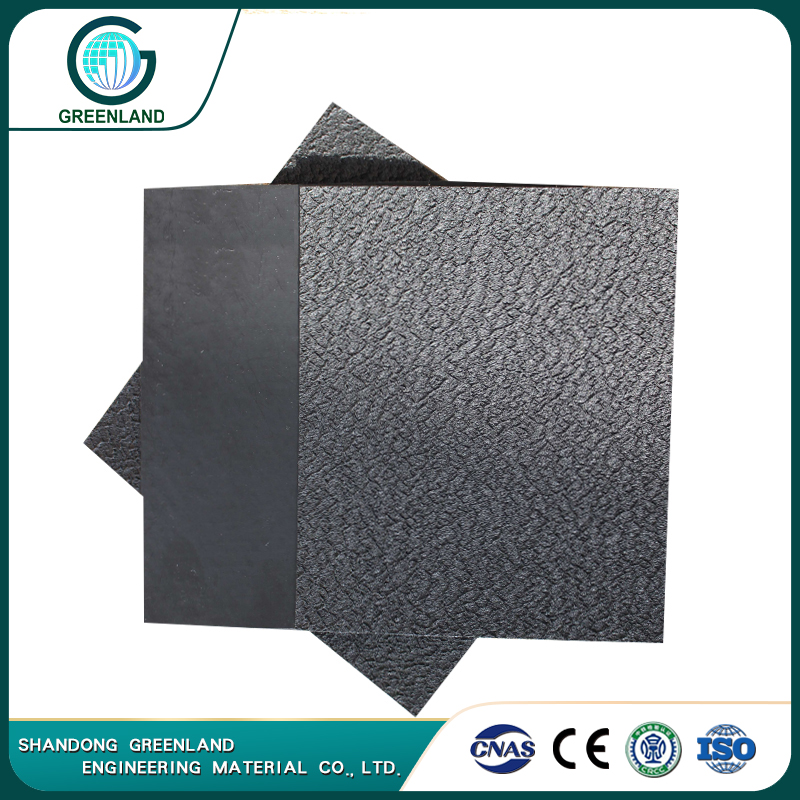

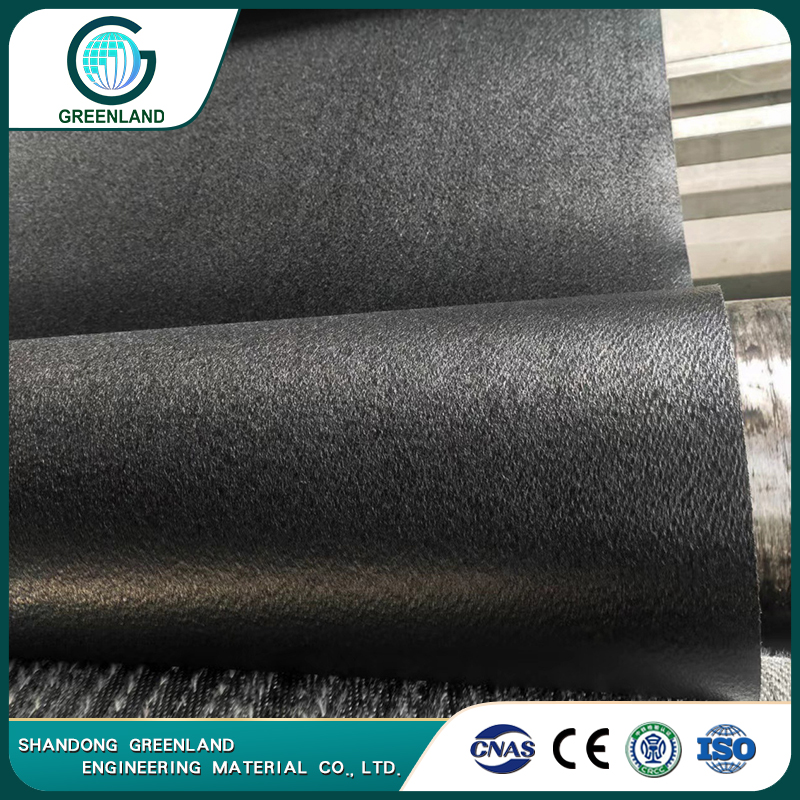

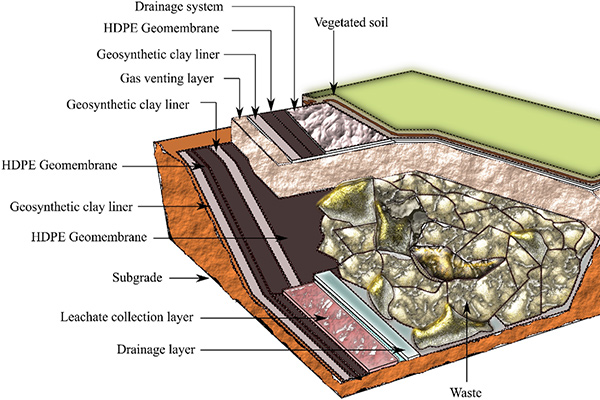

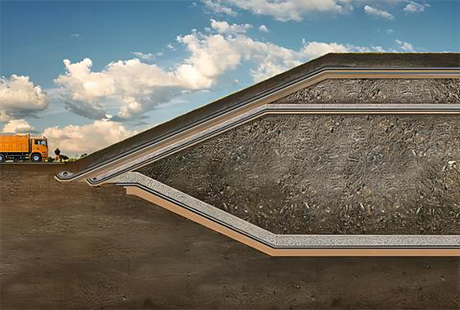

Greenland provide comprehensive range of geomembrane liners from a basic polyethylene through to reinforced flexible liners. Varying thicknesses of HDPE geomembranes are available from 0.2mm (including 0.5mm reinforced) to 4mm(20-160 mils) smooth, single and double textured geomembranes (often used in landfill cells).

Quick Details of HDPE/LDPE/LLDPE Geomembranes Liners

Quick Details of HDPE/LDPE/LLDPE Geomembranes Liners

| Products details information | |

| Product name | HDPE/LDPE/LLDPE Geomembranes Liners |

| Brand | Greenland (OEM is available) |

| Thickness | 0.2-4.0mm(20 mils-120 mils) |

| Raw material | HDPE, LDPE, LLDPE... |

| Application | Anti-seepage projects such as domestic waste landfill anti-seepage, solid waste landfill anti-seepage, sewage treatment plant anti-seepage, artificial lake anti-seepage, tailings treatment and other anti-seepage projects. |

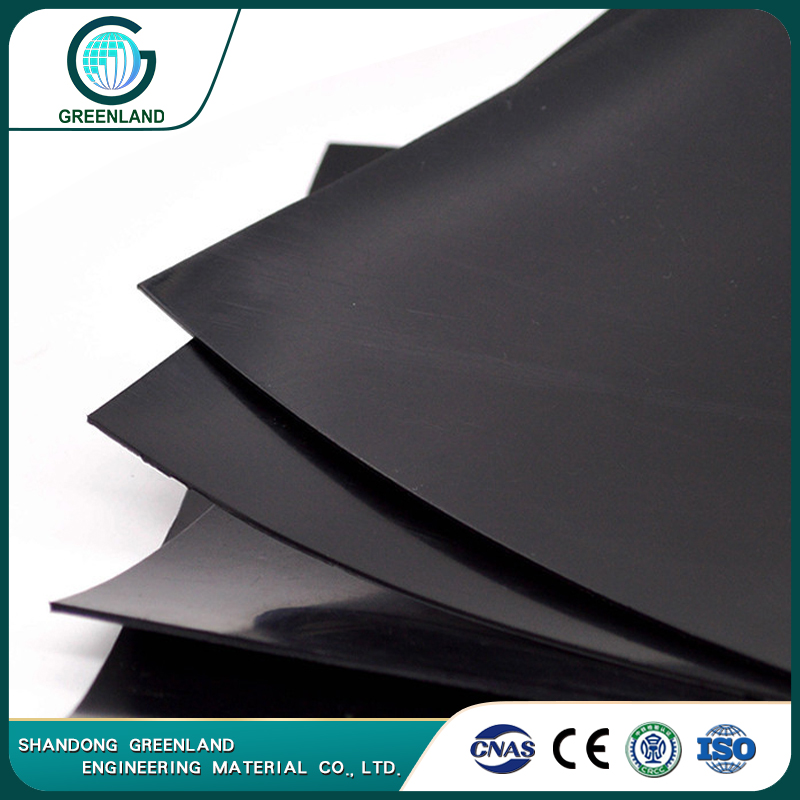

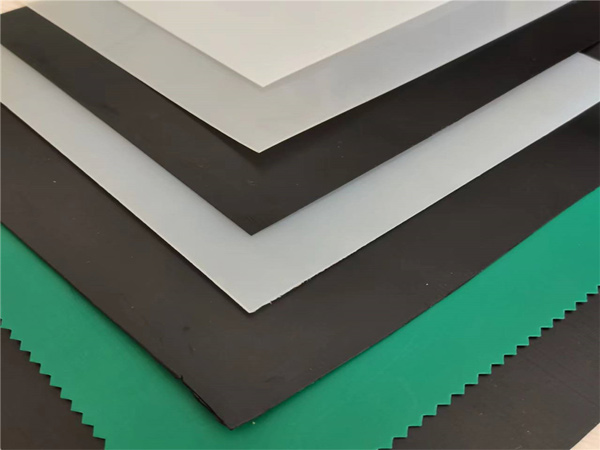

| Color | Black, White, other colors |

| Standards | ASTM, GRI, ISO, GH-1, GB/T17643, ects |

| Welding Tools | Hot air welding gun, geomembrane welding machine, etc |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Different Materials for HDPE/LDPE/LLDPE Geomembranes Liners

Different Materials for HDPE/LDPE/LLDPE Geomembranes Liners

Traditionally, PVC geomembranes have been the geomembrane used for canal-lining projects. However, recently polyethylene (PE) based geomembranes (HDPE, LDPE, LLDPE) as well as several other types of geomembranes (e.g. EDPM and polypropylene) have been used as canal liners.

The Most Commonly Used Type Of Geomembranes Liners on Market

The Most Commonly Used Type Of Geomembranes Liners on Market

| ❖HDPE Geomembranes | ❖PVC Geomembranes | ||

| ❖LLDPE Geomembranes | ❖Polypropylene(PP) Geomembranes | ||

| ❖EPDM Geomembranes | ❖TRP Geomembranes | ||

| ❖ECB Geomembranes | ❖EVA Geomembranes |

The history of HDPE liners started over 30 years ago. Today, geomembrane liners made of high-density polyethylene (HDPE) have become the product of choice in dozens of applications ranging from landfill liners and heap leach pads, to critical storage ponds and concrete protection membranes, which changed the purpose of landfill liners from a tool that minimizes leaks to a tool that drastically reduces and ideally prevents them altogether.

Geomembrane liners are also used in many applications including solid & liquid waste containment, amenity lakes & ponds, canal & watercourse lining, dams, balancing ponds, attenuation tank wrapping as a barrier layer on contaminated land.

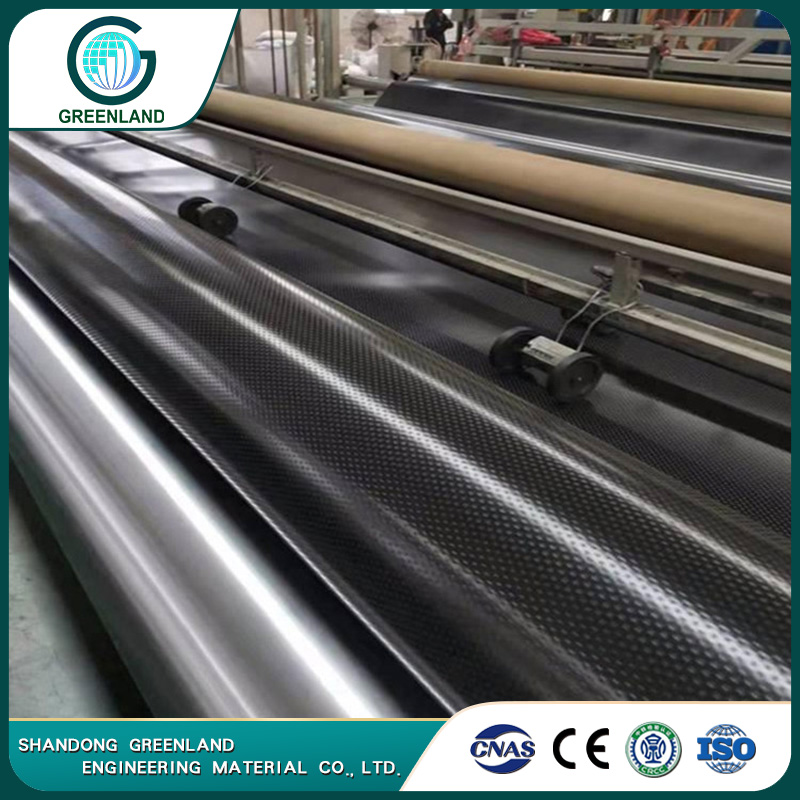

Different Kinds of HDPE/LDPE/LLDPE Geomembranes Liners

Different Kinds of HDPE/LDPE/LLDPE Geomembranes Liners

|

|

|

| Smooth HDPE Geomembranes | Smooth PE Geomembranes | Smooth HDPE Geomembranes in different color |

|

|

|

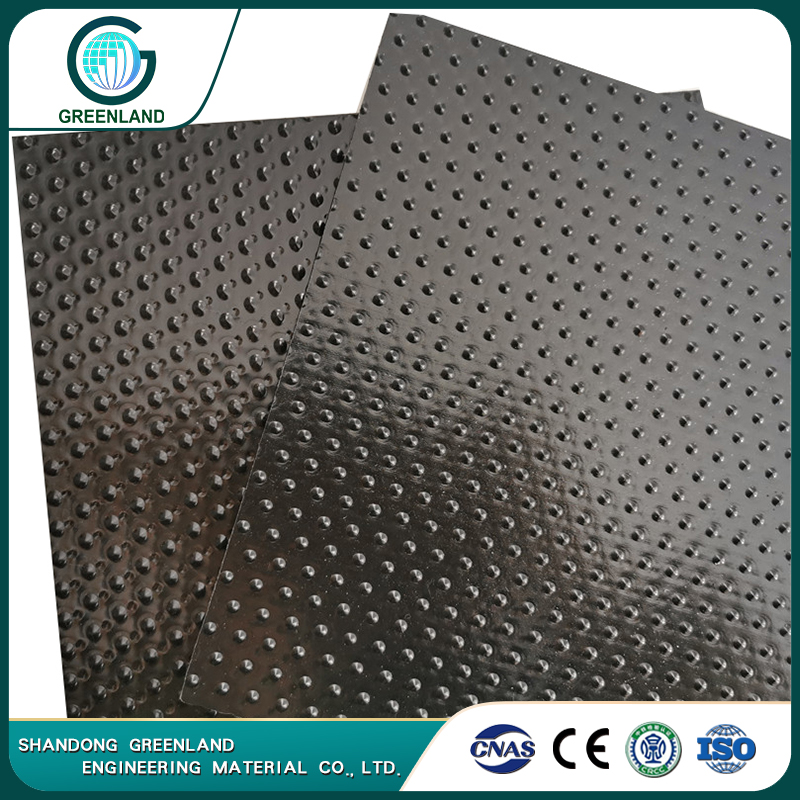

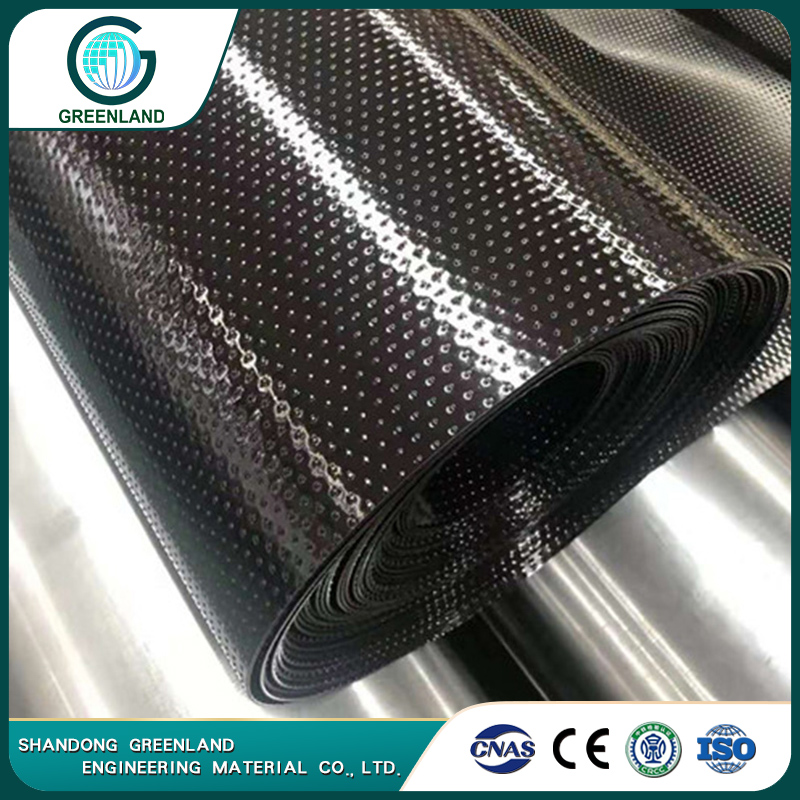

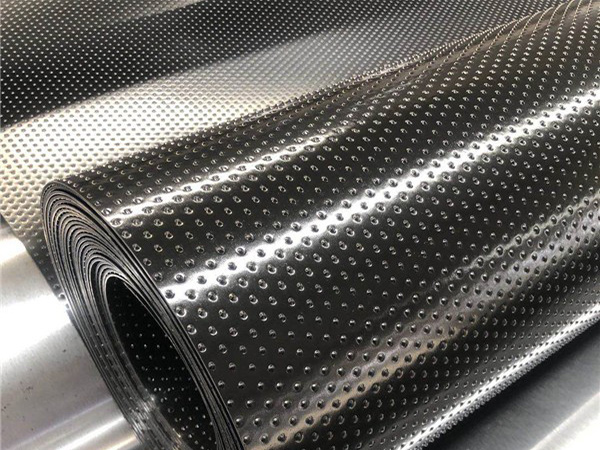

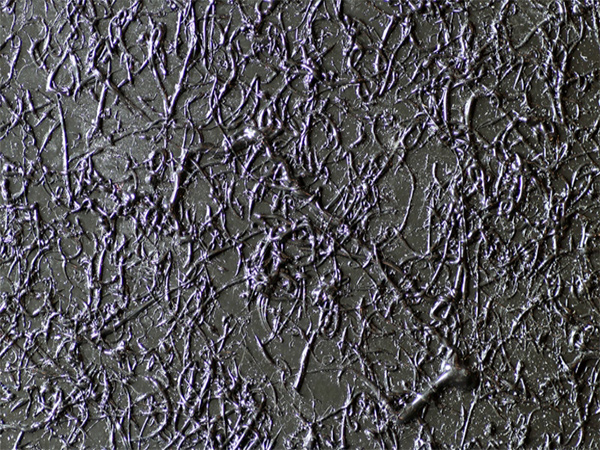

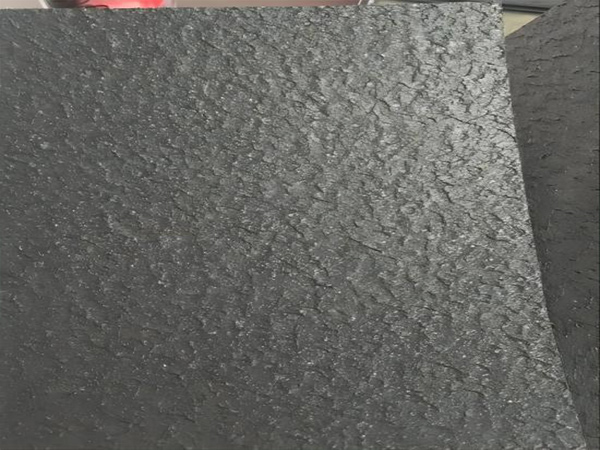

| HDPE Column Points Geomembrane | Spraying Textured HDPE Geomembrane | HDPE Textured Geomembranes |

❖Please Contact US and Get a Solutions of the Geomembrane Now.

Benefits of HDPE/LDPE/LLDPE Geomembranes Liners

Benefits of HDPE/LDPE/LLDPE Geomembranes Liners

The geomembranes known in the early 1980s, HDPE geomembranes quickly found favor as the landfill liner and became the top choice for lining applications worldwide , thanks to five driving properties: strength, flexibility, chemical and weather resistance, and ease of installation.

❖Impermeability

HDPE geomembrane has very low permeability, meaning they effectively prevent the passage of liquids and gases. This property makes them ideal for applications requiring containment, such as landfills, ponds, reservoirs, and wastewater treatment facilities.

❖Tear Resistance

HDPE geomembrane should have good tear resistance to prevent damage during installation and use. The tear resistance is typically specified in both the MD and CMD and can range from 25 N to 374 N (5.6 lb to 84 lb) in both directions.

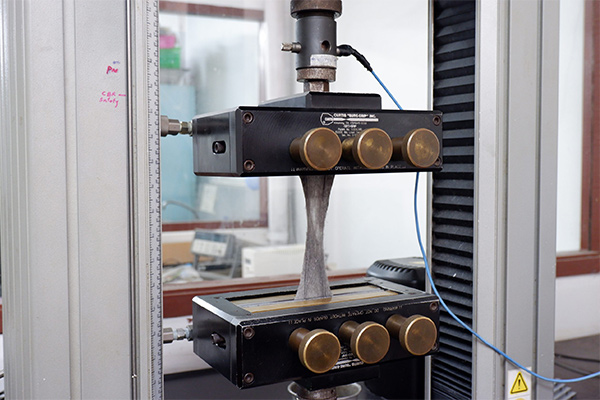

❖Tensile Strength

HDPE liners have high tensile strength to withstand stress and strains. The tensile strength is typically specified in both the machine direction (MD) and cross-machine direction (CMD). The values can vary but are commonly in the range of 3 kN/m to 80 kN/m (17 lb/in to 456 lb/in) in both directions.

❖Tear Resistance

HDPE geomembrane should have good tear resistance to prevent damage during installation and use. The tear resistance is typically specified in both the MD and CMD and can range from 25 N to 374 N (5.6 lb to 84 lb) in both directions.

❖Puncture Resistance

Puncture resistance is an important specification to consider, especially in applications where sharp objects or rocks may be present. HDPE liners generally have a puncture resistance ranging from 64 N to 960 N (14.5 lb to 215 lb).

❖Chemical Resistance

HDPE geomembranes exhibit excellent resistance to a wide range of chemical substances, including acids, alkalis, and various organic solvents. The specific chemical resistance properties should be evaluated based on the project requirements and chemical exposure.

❖Durability

HDPE geomembranes are highly durable and resistant to environmental stress cracking, UV radiation, and mechanical damage. They can withstand harsh weather conditions, temperature variations, and physical stresses associated with installation and use.

❖Flexibility

HDPE geomembranes have good flexibility, allowing them to conform to irregular surfaces and accommodate ground movements. This flexibility aids in the installation process and helps ensure proper containment.

❖Weldability

HDPE geomembranes can be easily joined together through thermal welding techniques. This enables the creation of large, continuous liner systems without the need for additional seams or connections, enhancing the overall integrity of the liner. Welding strength and integrity are important factors to consider. Weldability is the important consideration to ensure successful HDPE geomembrane installation.

❖Longevity

HDPE geomembranes have a long service life when installed and maintained properly. They can provide reliable containment for several decades, making them a cost-effective solution for long-term projects.

These properties and decades of excellent performance have solidified HDPE’s role within the containment industry. Thanks to these years of study, the precise role of HDPE as a liner has been established at a global scale.

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

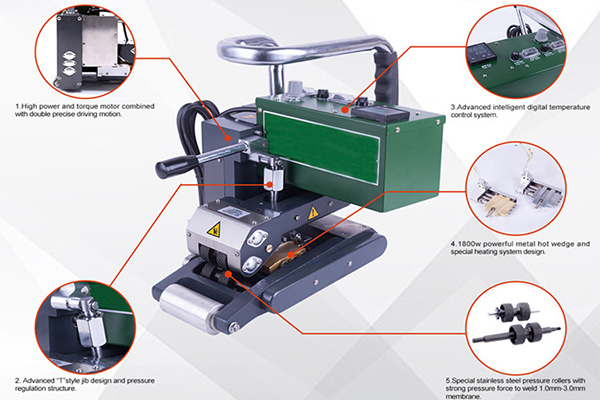

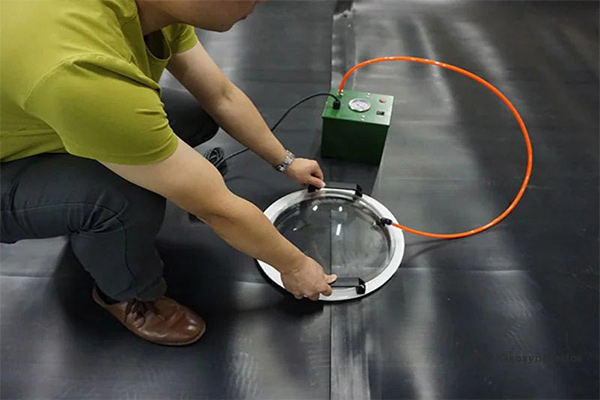

Installation Tools for the HDPE/LDPE/LLDPE Geomembranes Liners Greenland Provide

Installation Tools for the HDPE/LDPE/LLDPE Geomembranes Liners Greenland Provide

|

|

|

|

Gromembranes Welding Machine |

Air Pressure Testing Equipment |

Geomembrane Liner Leakage Detectors |

For the welding quality control of geomembrane, we usually use geomembrane liner leakage detectors, vacuum boxes, air pressure testing equipment and other equipment to perform quality control on the surface and welds of the geomembrane.

Packing of HDPE/LDPE/LLDPE Geomembranes Liners

Packing of HDPE/LDPE/LLDPE Geomembranes Liners

|

|

|

Packaged by the Woven bag |

Width: 2-8m, Lenght: 50-100m/Roll |

☎Please Contact us to Get More Details and Geomembrane Solutions, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Specifications of Diifferent Standard PE Geomembranes Liners

Specifications of Diifferent Standard PE Geomembranes Liners

1. HDPE/LDPE/LLDPE Smooth Surface Geomembrane (GB/T17643-2011 standard)

| Number | Item | Indicators | ||||||||

| Thickness(mm) | 0.3 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |

| 1 | Density(g/m³) | ≥0.940 | ||||||||

| 2 | Longitudinal and transverse tensile yield strength( N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

| 3 | Longitudinal and transverse tensile fracture strength(N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

| 4 | Longitudinal and transverse yield elongation( %) | - | - | ≥11 | ||||||

| 5 | Longitudinal and transverse elongation at break( %) | ≥600 | ||||||||

| 6 | Vertical and horizontal right angle tear load(N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

| 7 | Puncture resistance strength(N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

| 8 | Carbon black content(%) | 2.0~3.0 | ||||||||

| 9 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||||

| 10 | Induction time of atmospheric pressure oxidation(OIT)(min) | ≥60 | ||||||||

| 11 | Low temperature impact embrittlement performance | Pass | ||||||||

| 12 | Water vapor permeability coefficient(g·cm/(cm·s.Pa) | ≤1.0×10-13 | ||||||||

| 13 | Dimensional stability(%) | ±2.0 | ||||||||

| Note: The technical performance indicators for thickness specifications not listed in the table are required to be executed using interpolation method. | ||||||||||

2. Environmentally Friendly HDPE/LDPE/LLDPE Smooth Surface Geomembrane (GB/T17643-2011 GH-2S standard)

| Number | Item | Indicators | ||||||

| 1 | Thickness(mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 |

| 2 | Density(g/cm³) | ≥0.940 | ||||||

| 3 | Tensile yield strength (woven, transverse)N /mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (woven, transverse) N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse) % | ≥700 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

| 8 | Puncture resistance strength(N) | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 |

| 9 | Tensile load stress cracking (notch constant load tensile method) h | ≥300 | ||||||

| 10 | Carbon black content(%) | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | Atmospheric pressure oxidation induction time (OIT) (min) | Induction time of atmospheric pressure oxidation ≥100 | ||||||

| Induction time of high-pressure oxidation ≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

3. HDPE/LDPE/LLDPE Smooth Surface Geomembrane for Landfill Sites-Technical Specifications CJ/T 234-2006 (equivalent to US GRI-GM13 standard)

| Number | Item | Indicators | ||||||

| 1 | Thickness(mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 |

| 2 | Density(g/cm³) | ≥0.939 | ||||||

| 3 | Tensile yield strength (woven, transverse)N /mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (woven, transverse) N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse) % | ≥700 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥156 | ≥187 | ≥249 | ≥311 | ≥374 |

| 8 | Puncture resistance strength(N) | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 |

| 9 | Resistance to environmental stress cracking | ≥300 | ||||||

| 10 | Carbon black content(%) | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | Atmospheric pressure oxidation induction time (OIT) (min) | Induction time of atmospheric pressure oxidation ≥100 | ||||||

| Induction time of high-pressure oxidation ≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

4. HDPE/LDPE/LLDPE Rough Surface Geomembrane/Column Point Textured Geomembrane<GB/T17643-2011 GH-2T1 And GH-2T2 Technical Specifications>

| Number | Item | Indicators | ||||||

| Thickness (mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |

| 1 | Density (g/m³) | ≥0.940 | ||||||

| 2 | Roughness height (mm) | ≥0.25 | ||||||

| 3 | Tensile yield strength (longitudinal and transverse) N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (longitudinal and transverse) N/mm | ≥8 | ≥10 | ≥13 | ≥16 | ≥21 | ≥26 | ≥32 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse)% | ≥100 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

| 8 | Puncture resistance strength N | ≥200 | ≥270 | ≥335 | ≥400 | ≥535 | ≥670 | ≥800 |

| 9 | Tensile load stress cracking (notch constant load tensile method) h | ≥300 | ||||||

| 10 | Carbon black content % | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | oxidation induction time(OIT)(min) | Induction time of atmospheric pressure oxidation≥100 | ||||||

| Induction time of high-pressure oxidation≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

| Note: The technical performance indicators for thickness specifications not listed in the table are required to be executed using interpolation method. | ||||||||

❖The Other Specifications and Standards of the Geomembrane are not listed here, please contact to get it now.

☎Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Applications of Geomembrane Liners

Applications of Geomembrane Liners

Frozen, pooling, flowing, wastewater, and standing liquids can be hazardous if not properly managed. Hence, geomembranes are used to prevent the loss of material.

Geomembranes liners for various waste conveyance canals

Geomembranes liners used in tunnels and pipelines

Geomembranes liners for the agriculture industry

Geomembranes liners for potable or reserve water (for example, safe shutdown of nuclear facilities)

To contain and transport potable water and other liquids in the ocean

Geomembranes liners for the agriculture industry

Geomembranes liners used for fish pond liners

Geomembranes liners used for highways to prevent pollution from deicing salts

Geomembranes liners for primary, secondary, or/and tertiary waste piles and solid-waste landfills

Adjacent and beneath highways to capture hazardous liquid spills

Geomembranes liners for sewage sludge, radioactive or hazardous waste liquid

Geomembranes liners for emergency spillways

To contain and transport liquids in trucks

|

|

|

Geomembranes for Construction of Artificial Lake |

Geomembrane Liners for Dam |

|

|

|

Geomembranes for Isolation of Sewage& Landfill |

Geomembranes for Aquaculture |

|

|

|

Geomembranes liners for Mining |

Geomembrane Liners for Agriculture And Farming Pond |

☎Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

-

- Below are the detailed information of Geomembrane Liners for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST of Geomembrane Liners now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- HDPE Smooth Surface Geomembrane

DownLoad - PVC Geomembrane

DownLoad - LLDPE Geomembrane

DownLoad - HDPE Single Surface Geomembrane

DownLoad - HDPE Column Point Textured Geomembrane

DownLoad

Documents Download of Geomembrane Liners

Documents Download of Geomembrane Liners

Other CUSTOMIZED Geomembrane Liners have not been shown on above chart, please CONTACT US for more information

☎Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.