Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

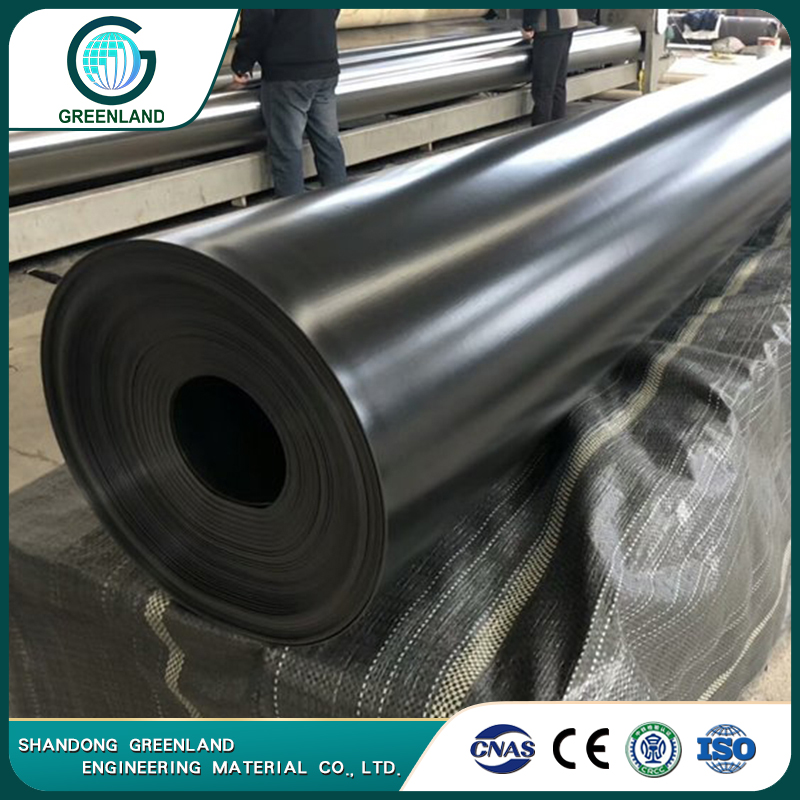

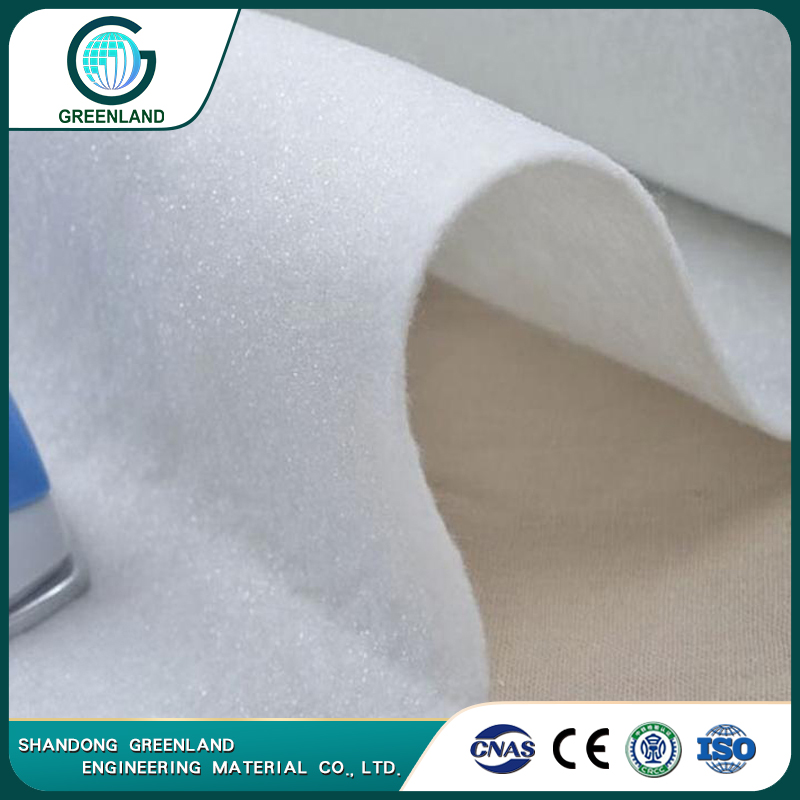

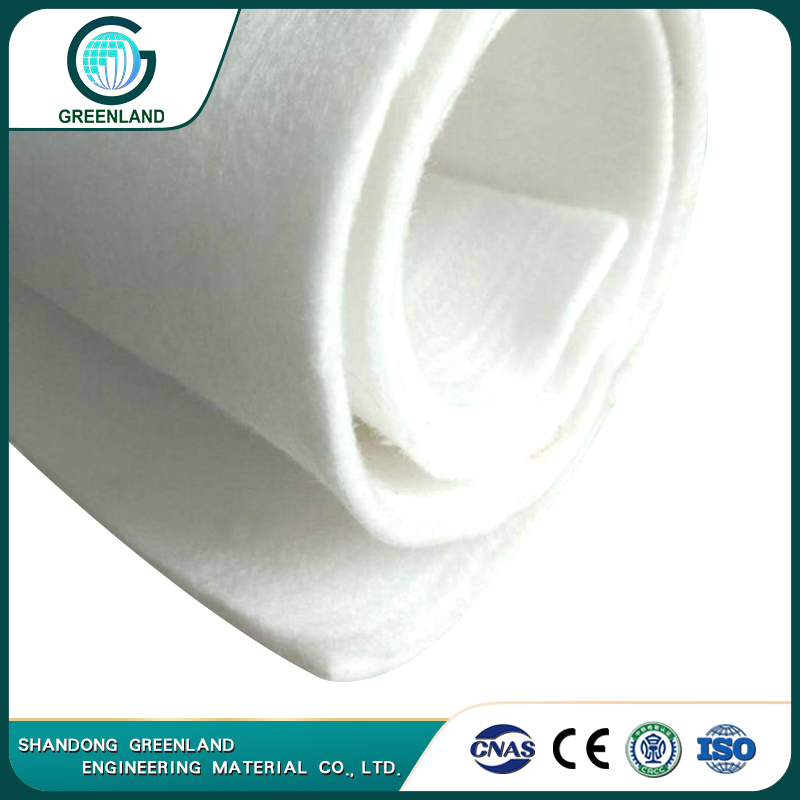

PP/PET Geotextile Fabrics

-

- 1. Thickness: 3-56kN/m or 100-1000g/㎡

- 2. Width: Max.8M

- 3. Raw material: PP. PET, etcs

- 4. Standards: EN, BS, GRI-GT12/GT13, ASTM, ISO, GB/T 17639-2008

- 5. Delivery period: stock, 5-10 days production date

- 6. Packing: 50-150m length/roll

- 7. MOQ: Trial order is acceptable

- 8. Free Sample is Available

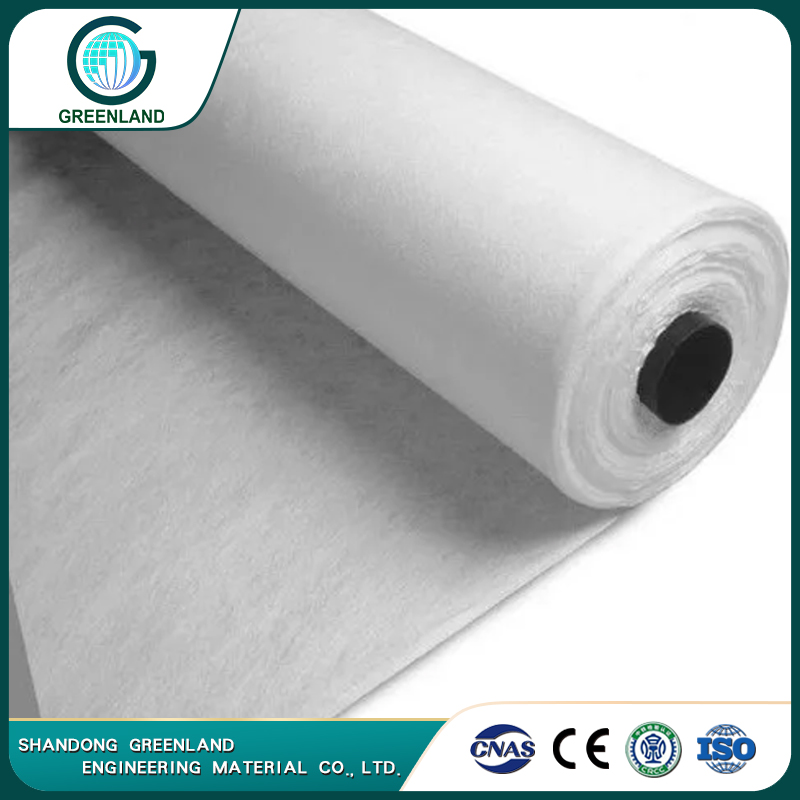

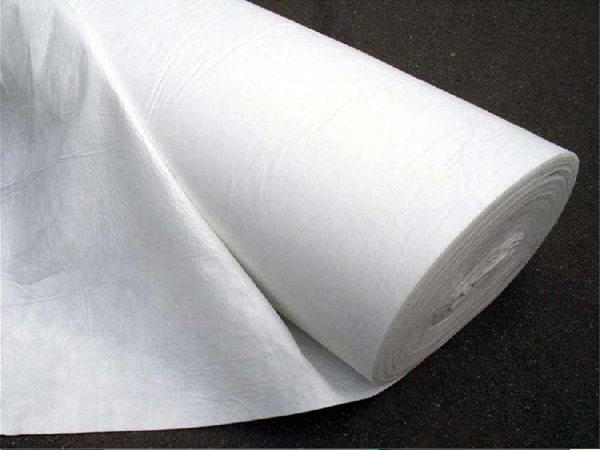

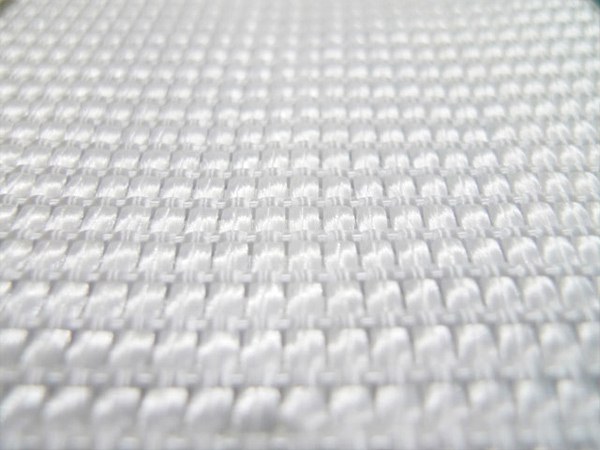

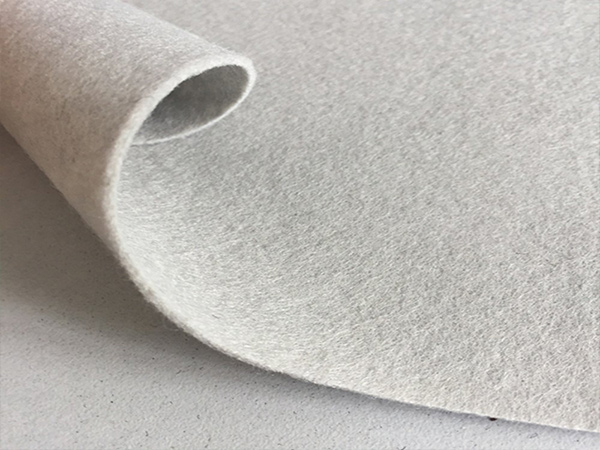

Geotextiles are versatile permeable fabrics that, when used in conjunction with soil, can effectively perform multiple functions, including separation, filtration, reinforcement, protection, and drainage. Typically crafted from polypropylene or polyester, Geotextile fabrics come in three basic forms: non- woven geotextiles, woven geotextiles (needle punched), or heat bonded geotextiles (structural woven).

Geotextiles are a relatively inexpensive product, that when designed and installed correctly can replace traditional granular treatments with significant cost savings.

Quick Details of Geotextile Fabrics-PP/PET Geotextile Fabrics

Quick Details of Geotextile Fabrics-PP/PET Geotextile Fabrics

| Products details information | |

| Product name | Geotextile Fabrics-PP/PET Geotextile Fabrics |

| Brand | Greenland (OEM is available) |

| Thickness | 3-56kN/m/100G-1000g/㎡ |

| Raw material | PP/PET |

| Application | separation, filtration, reinforcement, protection, and drainage |

| Color | Black, White, other colors |

| Standards | EN, BS, GRI-GT12/GT13, ASTM, ISO, GB/T 17639-2008 |

| Tools | Geotextile Cutting Tool, Bulldozers and Excavators, Anchors and retaining clamps, Seam material,Measuring Tools, Personal Protective Equipment, Road roller, Hand tools... |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

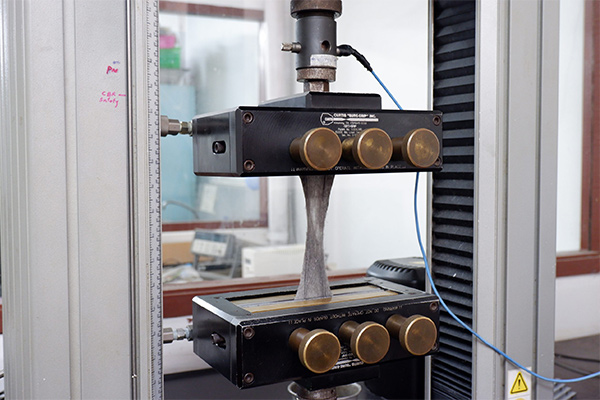

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Different Materials for Geotextile Fabrics-PP/PET Geotextile Fabrics

Different Materials for Geotextile Fabrics-PP/PET Geotextile Fabrics

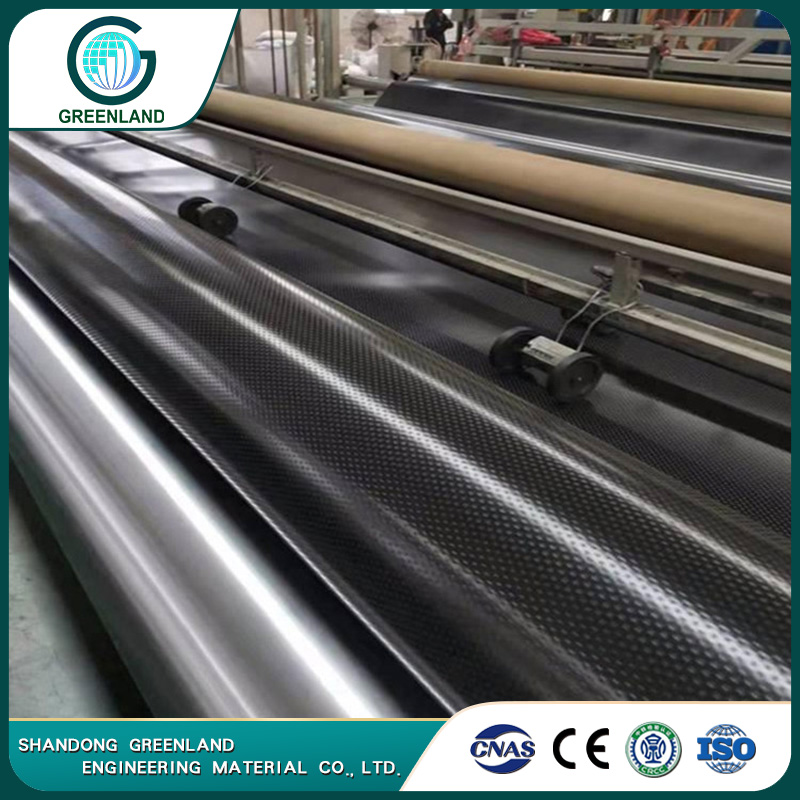

Traditionally, Geotextiles are permeable fabrics consisting mainly of materials such as polypropylene and polyester. Depending on their manufacturing method, they may be woven or non woven, based upon the type of application they are intended for. Woven and non woven fabrics have different production methods.

The Most Commonly Used Type Of Geotextile Fabrics-PP/PET Geotextile Fabrics

The Most Commonly Used Type Of Geotextile Fabrics-PP/PET Geotextile Fabrics

| ❖Woven Geotextiles | ❖Non-Woven Geotextiles | ||

| ❖Needle-Punched Geotextiles | ❖Composite Geotextiles | ||

| ❖High-Strength Geotextiles | ❖PP/PET Geotextiles | ||

| ❖Short Fiber /FilamentGeotextile | ❖Coir Fiber Geotextiles |

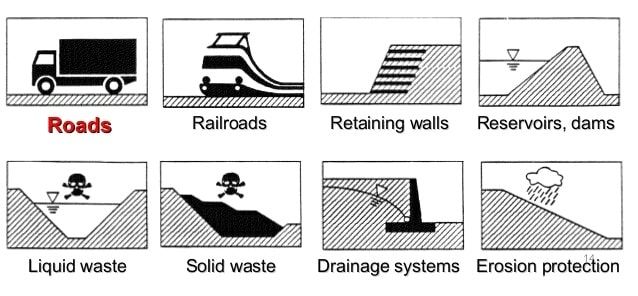

Geotextiles and related products have many applications and currently support many civil engineering applications including roads, airfields, railroads, embankments, retaining structures, reservoirs, canals, dams, bank protection, coastal engineering and construction site silt fences or to form a geotextile tube. Geotextiles can also serve as components of other geosynthetics such as the reinforcing material in a bituminous geomembrane. Usually geotextiles are placed at the tension surface to strengthen the soil. Geotextiles are also used for sand dune armoring to protect upland coastal property from storm surge, wave action and flooding. A large sand-filled container (SFC) within the dune system prevents storm erosion from proceeding beyond the SFC. Using a sloped unit rather than a single tube eliminates damaging scour.

Coir (coconut fiber) geotextiles are popular for erosion control, slope stabilization and bioengineering, due to the fabric's substantial mechanical strength.

Greenland Synthetics geotextile products incorporate the latest technology and state of the art materials. Using a range of polymers including polypropylene, polyester, polyethylene and aramid to ensure that the most durable polymer is used for performance in a range of environmental and service conditions. You are assured of the most advanced choice of materials when selecting a product supplied by us.

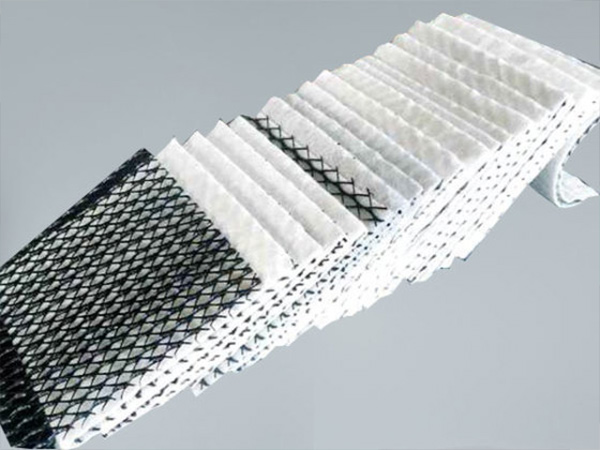

Different Kinds of Geotextile Fabrics-PP/PET Geotextile Fabrics

Different Kinds of Geotextile Fabrics-PP/PET Geotextile Fabrics

Woven geotextiles: These are made by weaving synthetic fibers together to create a robust and durable fabric. They are commonly used for applications that require high tensile strength and puncture resistance, such as underlayment for roads and railways, erosion control, and reinforcement of retaining walls.

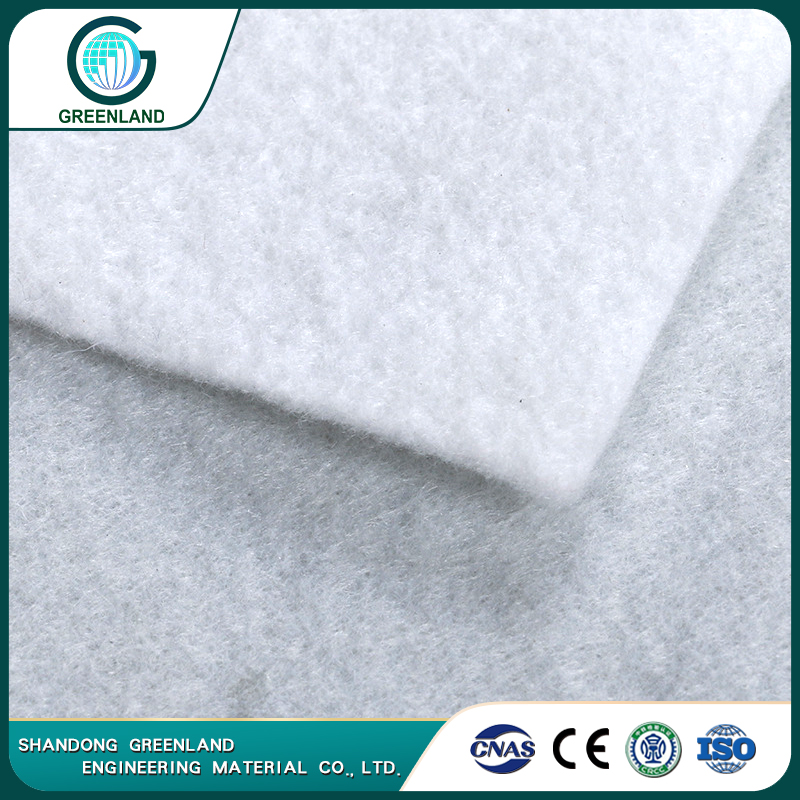

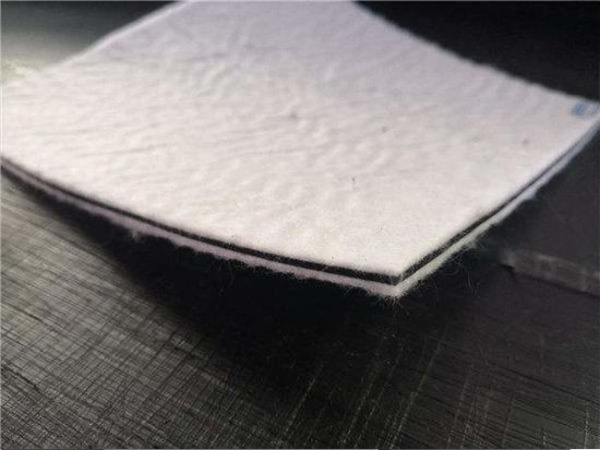

Non-woven geotextiles: They are made by bonding synthetic fibers together without weaving them. They are commonly used for applications that require good water permeability, such as drainage systems, filtration, and separation of different layers of soil or rock.

Needle-punched geotextiles: Needle-punched geotextile is made by mechanically punching and compacting fibers together. They are commonly used for applications that require good strength and filtration properties, such as erosion control, drainage systems, and soil stabilization.

Composite geotextiles: They are made by combining two or more types of geotextiles to create a material with unique properties. For example, a composite geotextile may combine a non-woven geotextile with a woven geotextile to create a strong, durable, and highly permeable material.

High-strength geotextiles: These are designed to provide exceptional tensile strength and puncture resistance. They are commonly used for applications requiring very high loads, such as reinforcing roadways, railways and retaining walls.

Though specific engineering and site conditions will determine which type of geotextile is used for a particular application.

|

|

|

| Woven Short& Filament Geotextiles | High-Strength Geotextiles | Short Fiber Composite Geotextiles |

|

|

|

| Needle-Punched Geotextiles | Composite Geotextiles | Composite Geotextiles& Geomembranes |

❖Please Contact US and Get a Solutions of the Geomembrane Now.

Benefits of Geotextile Fabrics-PP/PET Geotextile Fabrics

Benefits of Geotextile Fabrics-PP/PET Geotextile Fabrics

The geotextiles provide numerous benefits in civil engineering and environmental applications, including soil stabilization, erosion control, drainage improvement, separation, filtration, protection, reinforcement, cost-effectiveness, and environmental sustainability.

1. High strength. Due to the use of plastic fiber, it can maintain enough strength and elongation in dry and wet conditions..

2. Corrosion resistance, long-term corrosion resistance in soil and water with different pH.

3. Good water permeability, there are gaps between the fibers, so it has good water permeability.

4. Good antimicrobial property, no damage to microorganisms and insects.

5. Convenient construction. Because the material is light and soft, it is convenient to transport, lay and construct.

6. Complete specifications: width up to 9 meters. It is the widest product in China, the mass per unit area: 100-1000g/m2

7. Lightweight, low cost, corrosion resistance, excellent performance such as filter, drainage, isolation, and reinforcement.

When selecting a geotextile for a project, factors such as soil type, anticipated loads, and environmental conditions are typically considered.

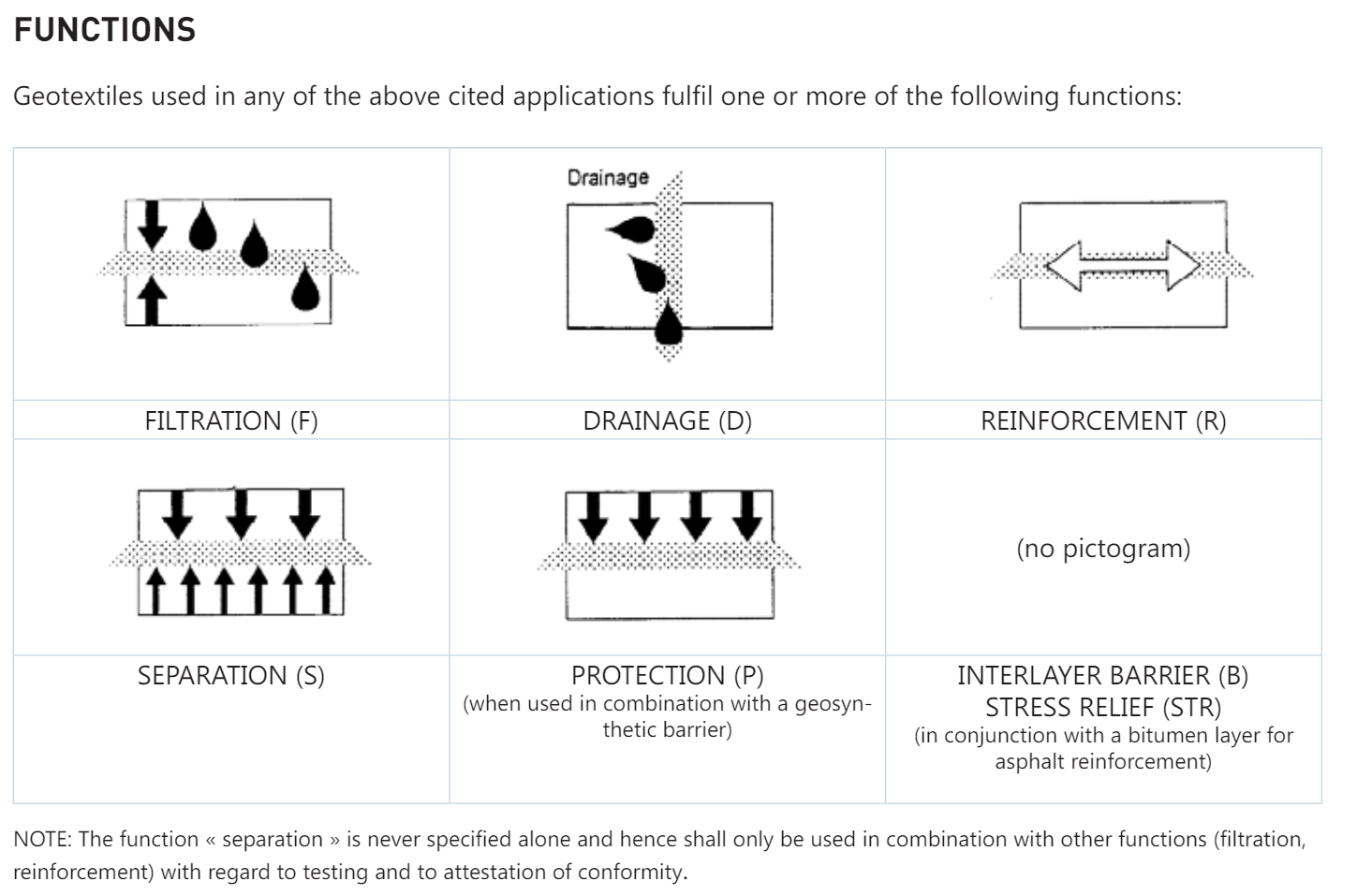

Geotextiles used in any of the above cited applications fulfil one or more of the following functions:

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

Packing of Geotextile Fabrics-PP/PET Geotextile Fabrics

Packing of Geotextile Fabrics-PP/PET Geotextile Fabrics

|

|

|

Packaged by the Woven bag |

Width: 2-8m, Lenght: 50-100m/Roll |

☎Please Contact us to Get More Details and Geotextile Fabrics Solutions, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Specifications of Diifferent Standard Geotextile Fabrics-PP/PET Geotextile Fabrics

Specifications of Diifferent Standard Geotextile Fabrics-PP/PET Geotextile Fabrics

1. PP (Polypropylene) Short Fiber Nonwoven Geotextile Technical Parameters(GB Standard)

| Mass per unit area (g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

| Deviation of mass per unit area, % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 |

| Thickness, mm ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 |

| Width deviation, % | -0.5 | ||||||||||

| Breaking strength, kN/m≥ | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 |

| Elongation at break, % | 25~100 | ||||||||||

| CBR breaking force, kN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 |

| Equivalent aperture O90, mm | 0.07~0.2 | ||||||||||

| Vertical permeability coefficient, cm/s | K×(10-1~10-3) | ||||||||||

| Tearing strength, kN | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 |

2. PP (Polypropylene) Short Fiber Nonwoven Geotextile Technical Parameters(ASTM Standard)

| Properties | TestMethod | Unit | GXSF150 | GXSF200 | GXSF300 | GXSF400 | GXSF500 | GXSF600 | GXSF800 | GXSF1000 |

| Tensile Strength (MD/TD) |

ASTM D4595 | kN/m | 8 | 11 | 20 | 24 | 28 | 34 | 48 | 50 |

| Tensile Elongation (MD/TD) |

ASTM D4595 | % | 50 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Grab Tensile Strength (MD/TD) |

ASTM D4632 | N | 520 | 700 | 1100 | 1500 | 1800 | 2200 | 2800 | 3000 |

| Grab Elongation (MD/TD) |

ASTM D4632 | % | 50 | 50 | 60 | 60 | 60 | 60 | 60 | 60 |

| Trapezoidal Tear Strenath (MD/TD) |

ASTM D4533 | N | 220 | 330 | 400 | 480 | 560 | 620 | 860 | 880 |

| CBR Burst Strength |

ASTM D6241 | N | 1700 | 2400 | 3200 | 4300 | 5300 | 6000 | 6800 | 7000 |

| Pore Size O90 | ASTM D4751 | μm | 90 | 85 | 80 | 75 | 70 | 60 | 55 | 50 |

| Water Flow Q100 |

ASTM D4491 | L/m2/s | 160 | 145 | 140 | 120 | 105 | 95 | 90 | 80 |

| Weight | ASTM D5261 | g/m2 | 150 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 |

| Roll Width | m | 5.95 | 5.95 | 5.95 | 5.95 | 5.95 | 3.95 | 3.95 | 3.95 | |

| Roll Length | m | 250 | 150 | 100 | 100 | 75 | 50 | 50 | 50 | |

| Notes (1) MD = Machine Direction; TD= Transverse Direction (2)Roll width can be 1m, 2m, 3m, 3.95m, 5.95m or as per customized. |

||||||||||

3. PP (Polypropylene) Filament Spunbond Needle Punched Nonwoven Geotextile New Standard (GB/T 17639-2008)

| Item | Values | ||||||||||

| Specifications | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

| Thickness ≥(mm) | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.2 | 5.5 |

| Breaking strengt ≥(kN/m) | 4.5 | 7.5 | 10.0 | 12.5 | 15.0 | 17.5 | 20.5 | 22.5 | 25.0 | 30.0 | 40.0 |

| Elongation at break (%) | 40-80 | ||||||||||

| CBR puncture resistance ≥(kN) | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3.0 | 3.5 | 4.0 | 4.7 | 5.5 | 7.0 |

| Tearing strength ≥(kN) | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.70 | 0.82 | 1.10 |

| Equivalent Pore size 090(095) (mm) | 0.05-0.2 | ||||||||||

| Vertical permeability coefficient | K×(10-1-10-3)cm/s (K=1.0~9.9) | ||||||||||

| Width deviation % | -0.5 | ||||||||||

| Mass deviation per unit area % | -5 | ||||||||||

4. New Standard for Filament Nonwoven Geotextile (GB/T 17639-2008)

| Item | Index | ||||||||

| Nominal breaking strength | 4.5 | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 |

| Longitudinal and transverse rupture strength, kN/m ≥ | 4.5 | 7.5 | 10.0 | 15.0 | 20.0 | 25.0 | 30.0 | 40.0 | 50.0 |

| Standard strength corresponds to elongation, % | 40~80 | ||||||||

| CBR burst strength/kN ≥ | 0.8 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

| Longitudinal to tear strength/kN ≥ | 0.14 | 0.21 | 0.28 | 0.42 | 0.56 | 0.7 | 0.82 | 1.1 | 1.25 |

| Equivalent aperture O90/mm | 0.05~0.20 | ||||||||

| Thickness/mm ≥ | 0.8 | 1.2 | 1.6 | 2.2 | 2.8 | 3.4 | 4.2 | 5.5 | 6.8 |

| Width deviation, % | -0.5 | ||||||||

| Deviation of mass per unit area, % | -5 | ||||||||

❖The Other Specifications and Standards of the Geotextile Fabrics are not listed here, please contact to get it now.

☎Please Contact us to Get More Geotextile Fabrics Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Applications of Geotextile Fabrics-PP/PET Geotextile Fabrics

Applications of Geotextile Fabrics-PP/PET Geotextile Fabrics

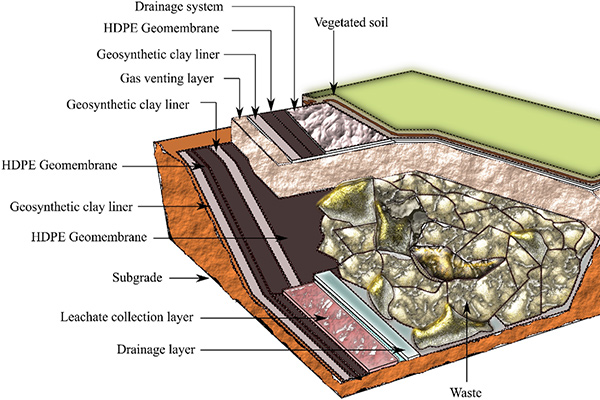

Geotextiles have played a crucial role in the field of geotechnical engineering, the major applications of geotextiles include road construction, erosion prevention, and drainage systems.

❖1. Drainage

Geotextiles will efficiently collect surplus water from structures, such as rainwater or surplus water, from the soil and discharge it.

❖2. Filtration

Our geotextiles provide superior hydraulic flow and soil retention, which makes them well suited for filtration in subsurface drainage applications and under hard armour systems.

❖3. Separation

Geotextiles are used for paved and unpaved roads, where ground conditions have been compromised. As a separation layer, geotextiles can aid preventing the intermixing of dissimilar materials, add to the performance life of the road and reduce the overall thickness of the road section by requiring less aggregate during construction.

❖4. Reinforcement

High strength geotextiles can be used to reinforce earth structures as the strength of the tape or filament within the fabric may be increased to suit a specific application. Thanks to their high tensile strength they are an ideal reinforcement solution.

❖5. Protection

Due to the consistent thickness and weight of our Geotextiles, they provide adequate cushioning and protection for critical lining systems.

Two types of geotextiles, woven and nonwoven, are the common solution for soil separation and filtration needs. Projects where these are typically used, include:

Landfill lining systems

Wastewater treatment lagoon lining systems

Retention and decorative pond lining systems

Erosion control projects

Drainage projects

Road construction and rehabilitation work

Site development works

Commercial landscaping work

|

|

|

Geotextiles for Road Construction |

Geotextiles for Drainage Projects |

|

|

|

Geotextiles for Site Development Works |

Geotextiles for Erosion Control Projects |

☎Please Contact us to Get More Details About the Geotextiles, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Geotextile Fabrics-PP/PET Geotextile Fabrics

-

- Below are the detailed information of Geomembrane Liners for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST of Geomembrane Liners now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- PP Short Fiber Non-Woven Geotextile

DownLoad - PET Short Fiber Non-Woven Geotextile

DownLoad - Filament Geotextile Composite Geomembrane

DownLoad - PET (Polyester) Filament Spunbond Needle Punched Nonwoven Geotextiles

DownLoad

Documents Download of Geotextile Fabrics-PP/PET Geotextile Fabrics

Documents Download of Geotextile Fabrics-PP/PET Geotextile Fabrics

Other CUSTOMIZED Geomembrane Liners have not been shown on above chart, please CONTACT US for more information

☎Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.