Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

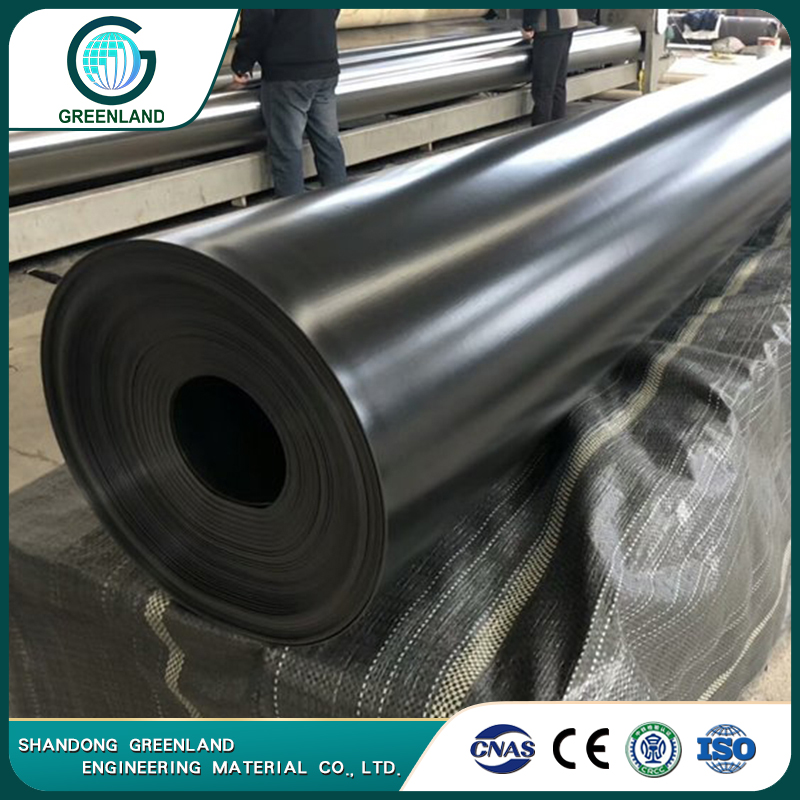

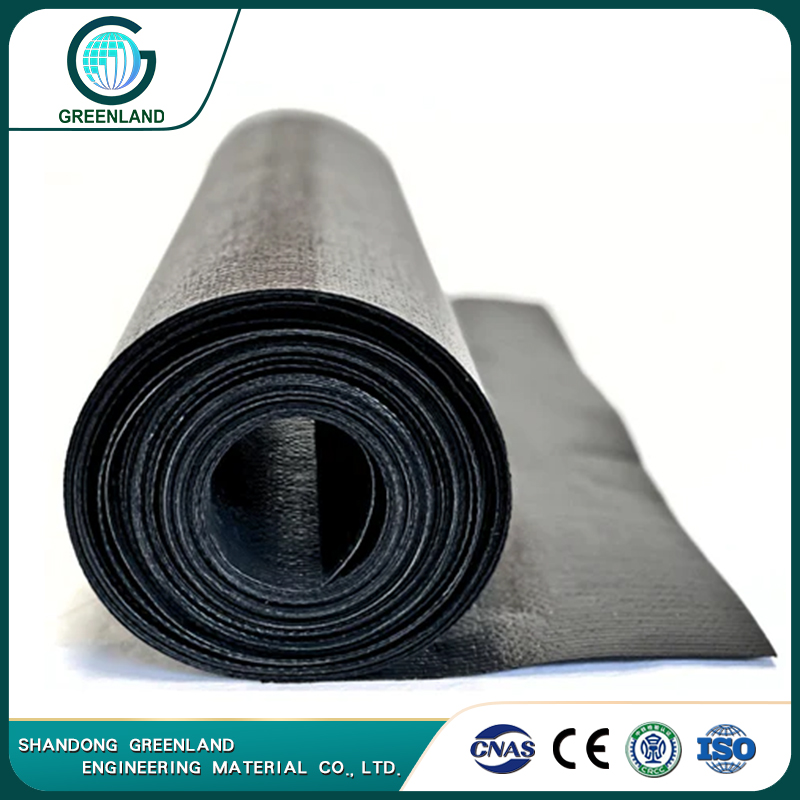

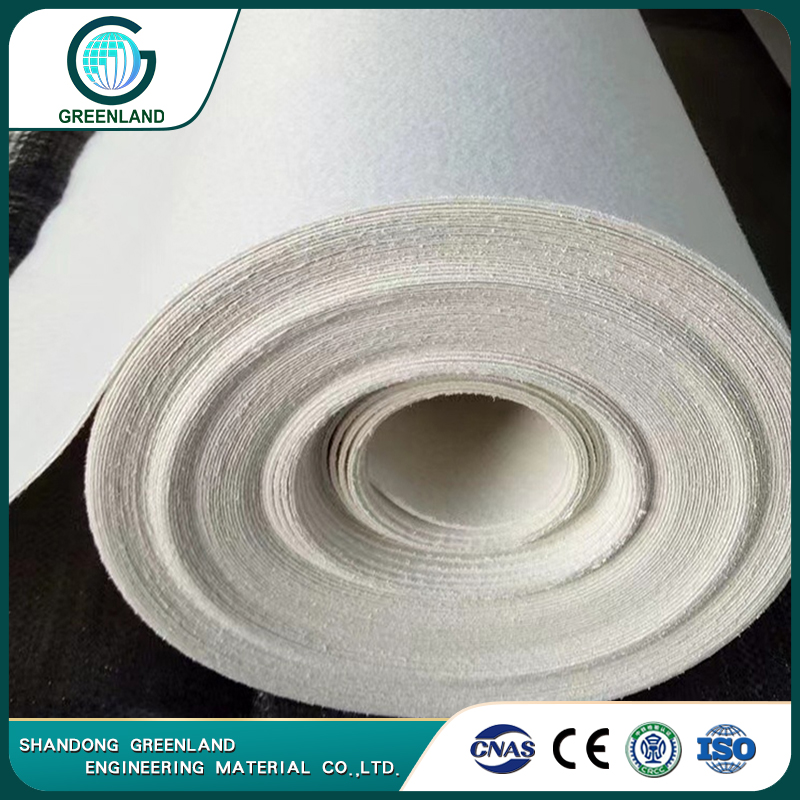

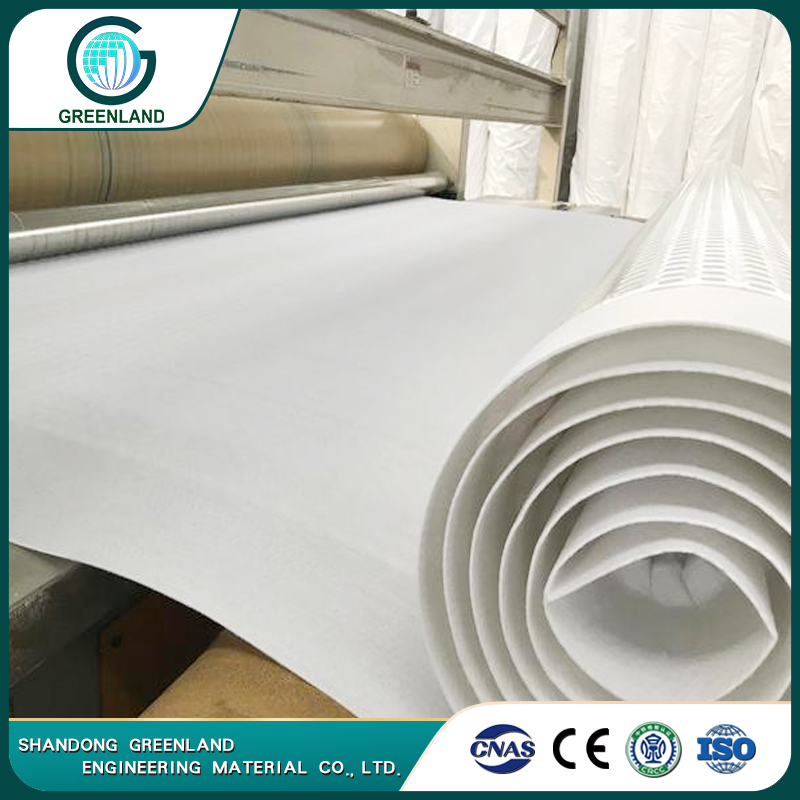

Composite Geomembrane Liner

-

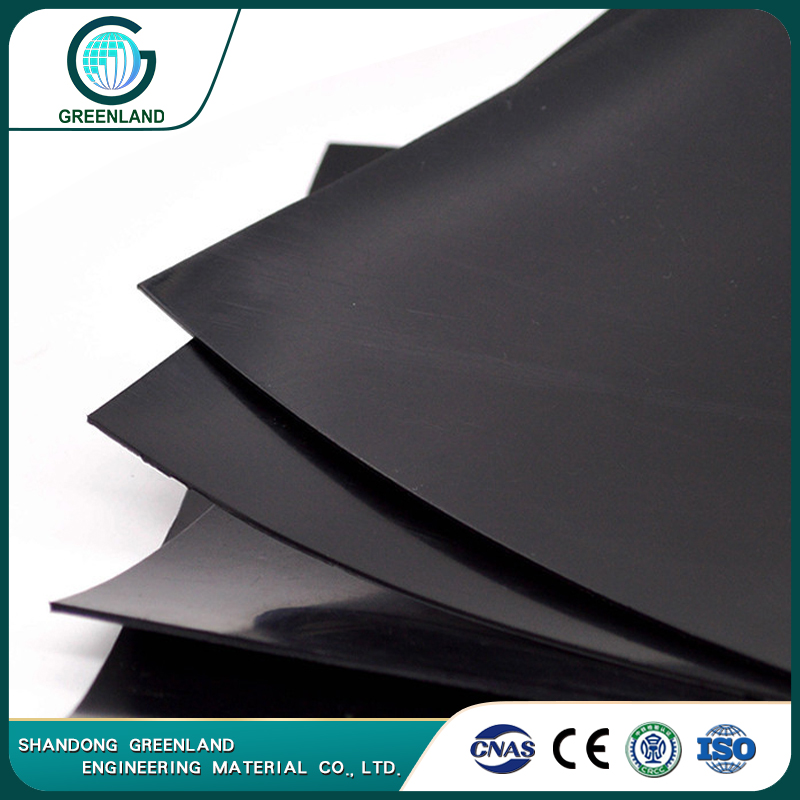

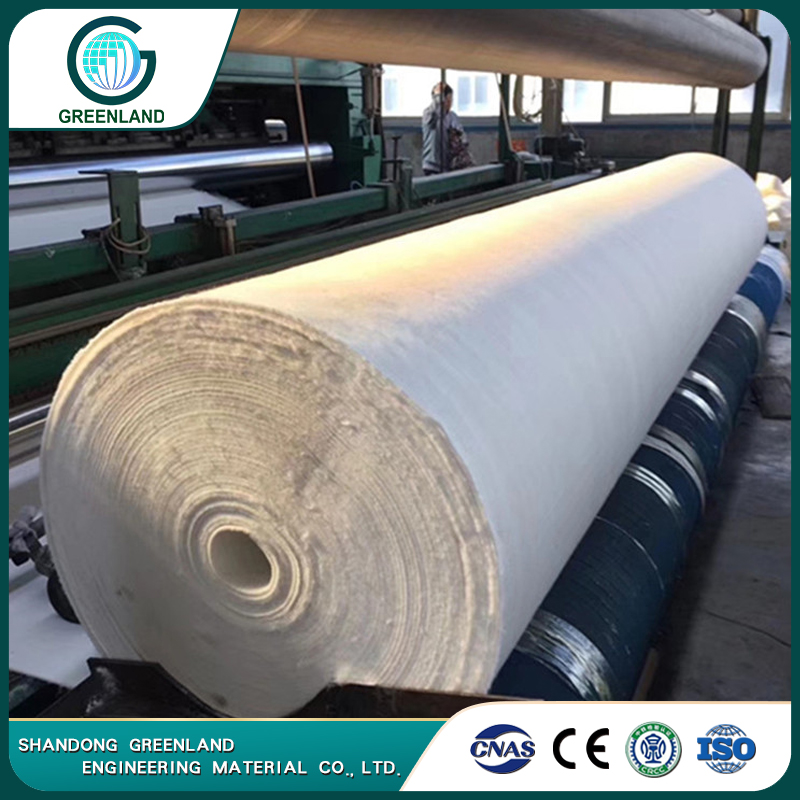

- 1.Thickness: 0.2-4.0mm(20 mils-120 mils)

- 2.Width: Max. 8M

- 3.Raw Material: HDPE, MDPE, LDPE, LLDPE, ECB, EPDM, BGM, EVA, PP, GCLS, GSPE, EPDM…

- 4.Standard: ASTM, GRI, ISO, GH-1, GB/T17643-2023

- 5.Delivery: Stock for regular item, 5-10 Days for Production

- 6.Packing: 50-100m length/roll, Customized

- 7.MOQ: Trial order is acceptable

- 8.Free Sample Available

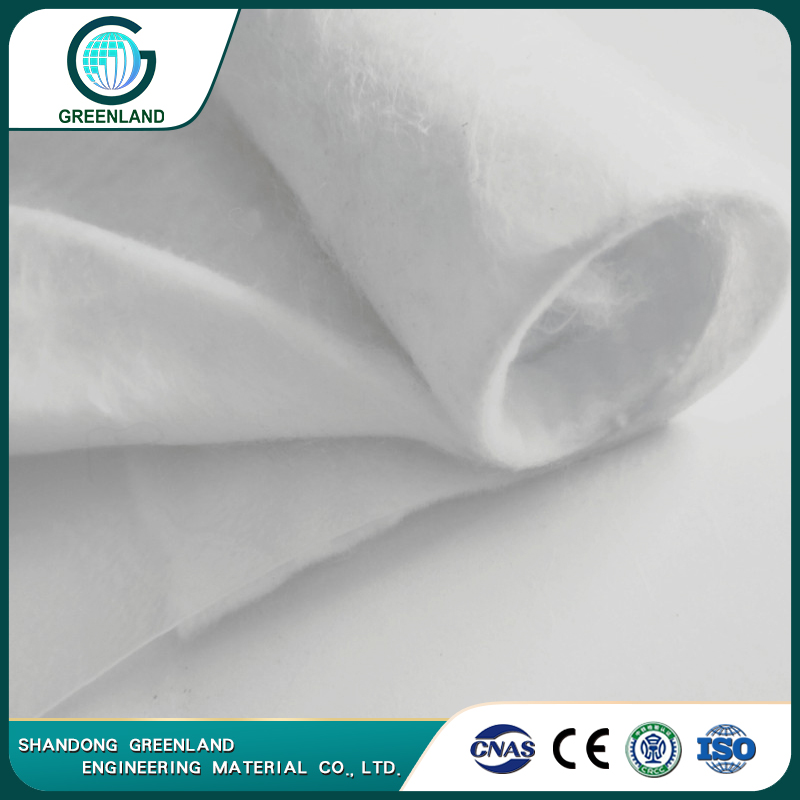

Composite Geomembrane Liner is made by heat-bonding nonwoven or woven geotextile combined with HDPE geomembranes by calendaring processing technology. Greenland composite geomembrane liner is automatically formed by pressing one or two geotextile layer to the geomembrane layer in the continuous far infrared ray heating oven, polymer and anti-aging materials are added in the production process at the same time, so it can be used in unconventional temperature environment.

Quick Details of Composite Geomembrane Liner

Quick Details of Composite Geomembrane Liner

| Products details information | |

| Product name | Composite Geomembrane Liner |

| Brand | Greenland (OEM is available) |

| Thickness | 0.2-4.0mm(20 mils-120 mils) |

| Raw material | HDPE, LDPE, LLDPE, EVA, ECB, PVC, PP, GCLS, GSPE, EPDM... |

| Application | Anti-seepage projects such as domestic waste landfill anti-seepage, solid waste landfill anti-seepage, sewage treatment plant anti-seepage, artificial lake anti-seepage, tailings treatment and other anti-seepage projects. |

| Color | Black, White, other colors |

| Standards | ASTM, GRI, ISO, GH-1, GB/T17643, ects |

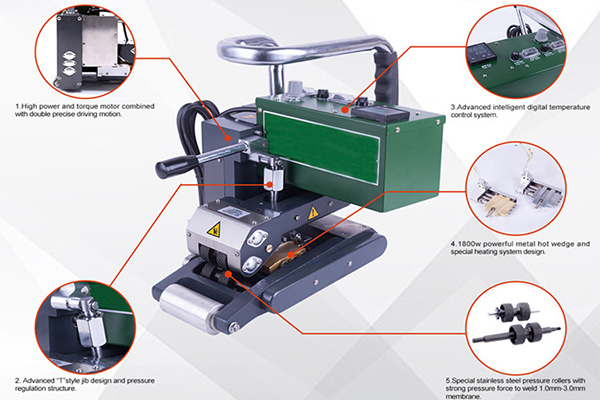

| Welding Tools | Hot air welding gun, geomembrane welding machine, etc |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

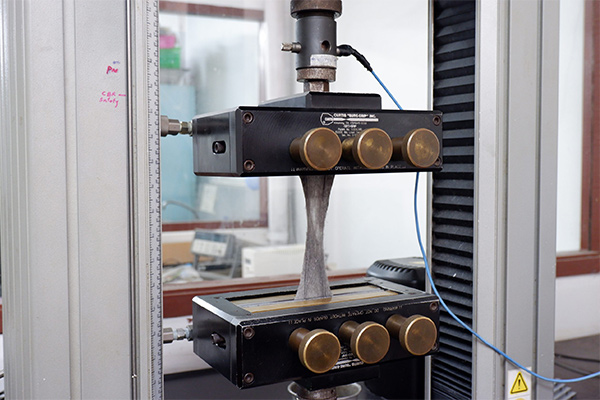

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

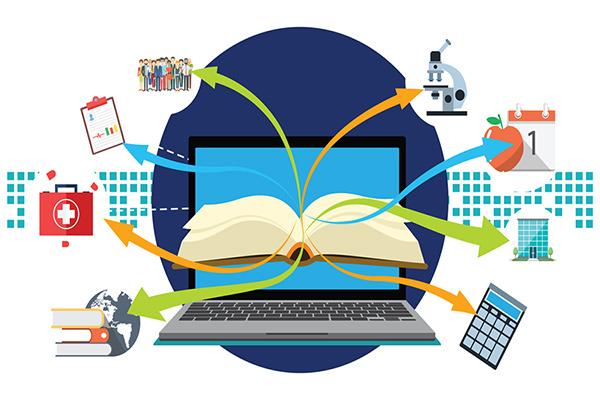

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Different Materials for Composite Geomembrane Liner

Different Materials for Composite Geomembrane Liner

Traditionally, PVC geomembranes have been the geomembrane used for canal-lining projects. However, recently polyethylene (PE) based geomembranes (HDPE, LDPE, CSPE and VLDPE) as well as several other types of geomembranes (e.g. EDPM and polypropylene) have been used as canal liners.

The Most Commonly Used Type Of Composite Geomembrane Liner

The Most Commonly Used Type Of Composite Geomembrane Liner

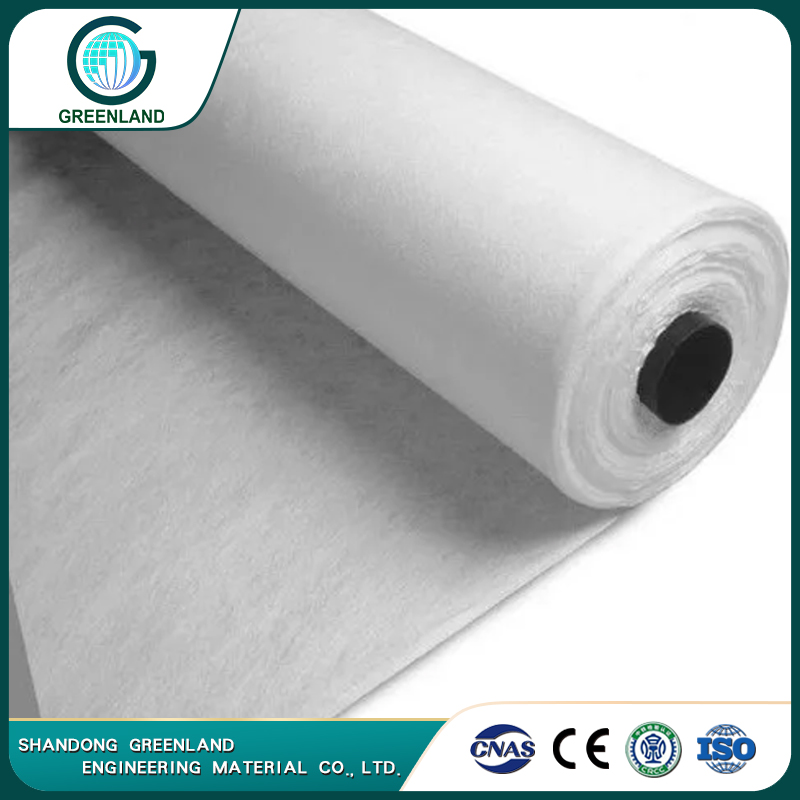

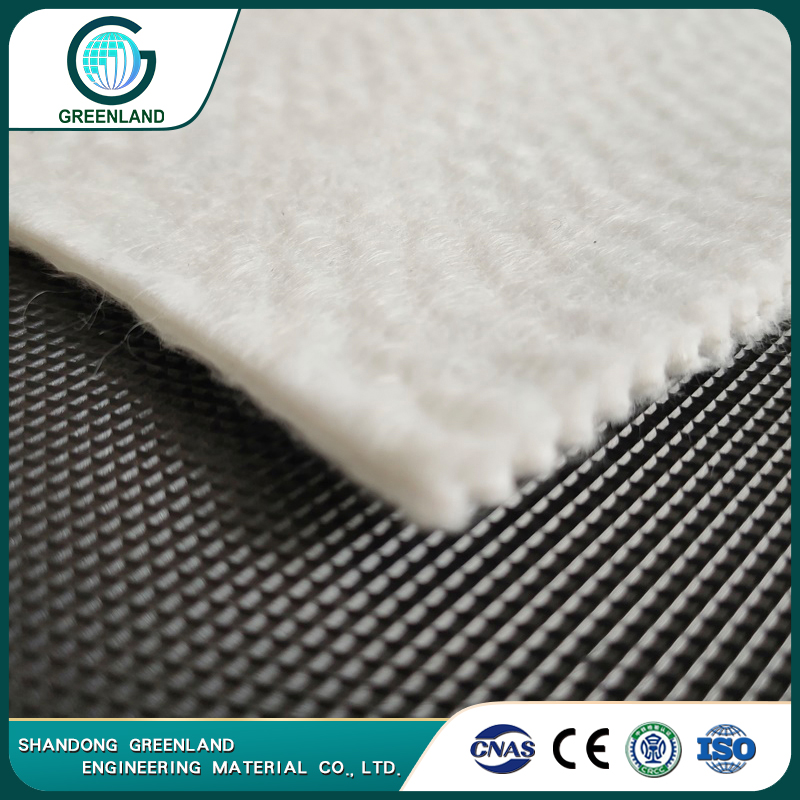

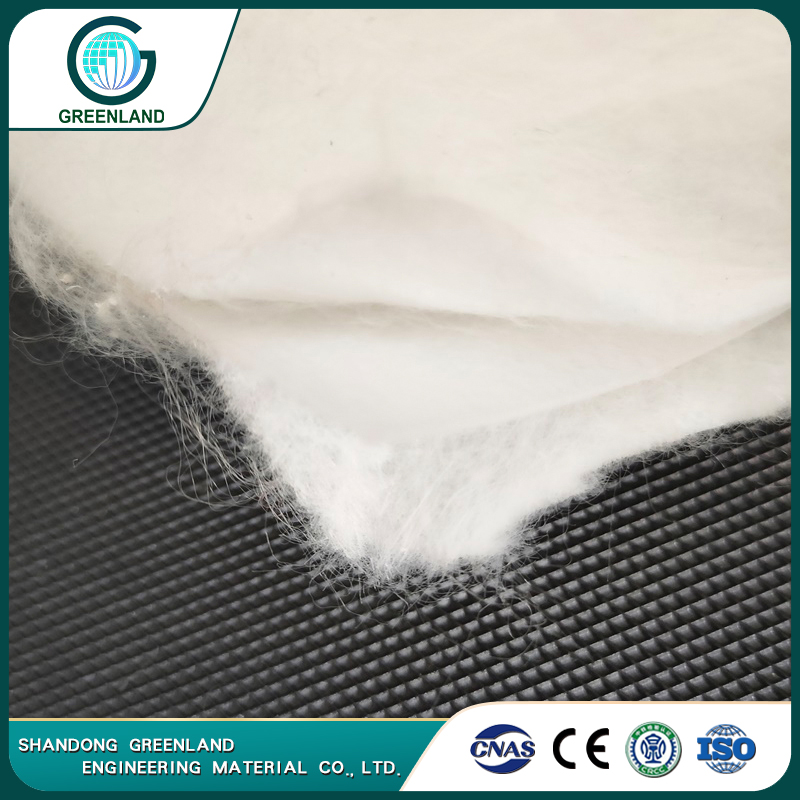

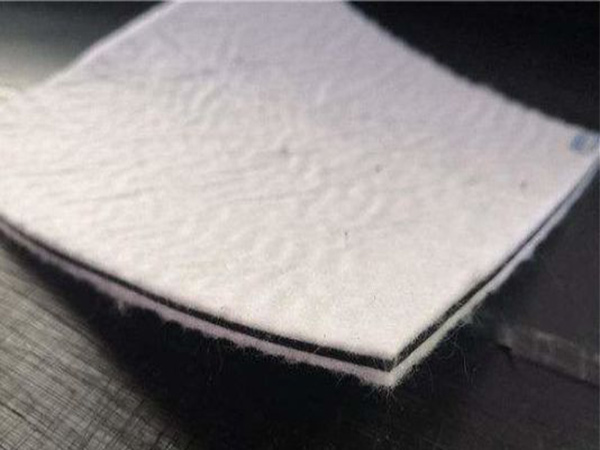

| ❖CG11 series | one layer of membrane and one layer of geotextile Geotextile: 100-1000g/m²; Geomembrane: 0.1-1.5mm |

||

| ❖CG21 series | two layers of membrane and one layer of geotextile Geotextile: 80-600g/m²; Geomembrane: 0.2-1.5mm |

||

| ❖CG12 series | one layer of membrane and two layers of geotextile Geotextile: 100-1000g/m²; Geomembrane: 0.1-0.8mm |

||

| ❖CG-multi | Multiple layers. Geotextile: 100-1500g/m²; Geomembrane: 0.1-2mm |

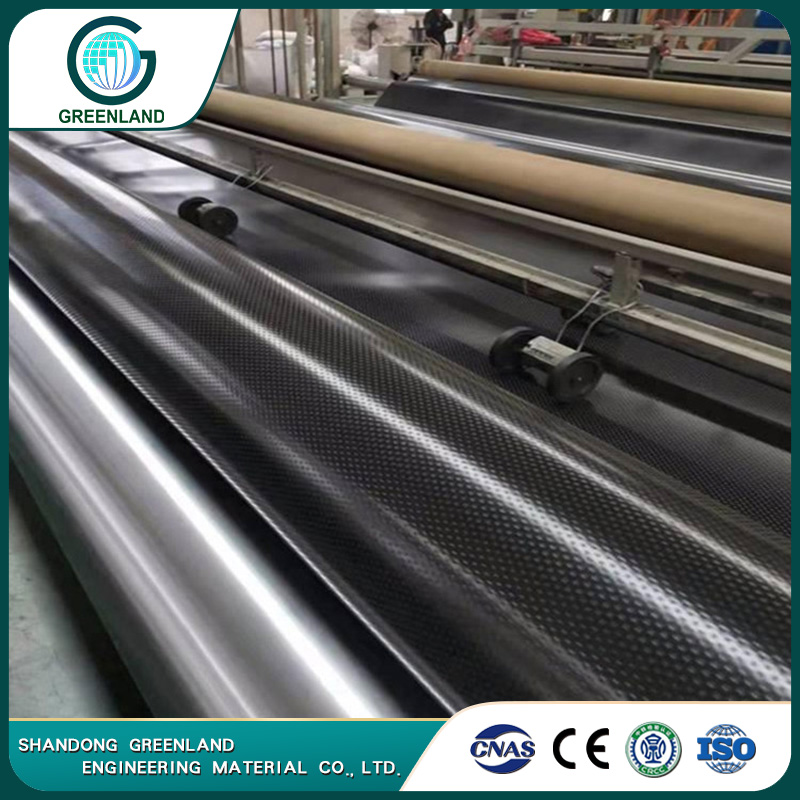

❖The membrane could be Smooth Geomembrane, Textured Geomembrane, and the geotextile will be non-woven or woven geotextiles, so many options for your chioces.

The composite geomembrane liner combines the benefits of geotextiles and geomembranes, offering a versatile solution for various applications. The inclusion of a geotextile layer enhances the liner’s tensile strength, while the geomembrane component provides exceptional impermeability, leak resistance, moisture-proofing, tear resistance, and puncture resistance.

Different Kinds of Composite Geomembrane Liner

Different Kinds of Composite Geomembrane Liner

|

|

|

| Composite Geomembrane Liner | Composite Geomembrane Liner | Composite Geomembrane Liner |

|

|

|

| Composite Geomembrane Liner | Composite Geomembrane Liner | Composite Geomembrane Liner |

❖Please Contact US and Get a Solutions of the Composte Geomembrane Liner Now.

Benefits of Composite Geomembrane Liner

Benefits of Composite Geomembrane Liner

Geomembrane is regularly used for the containment of hazardous liquids that can contaminate the ground or surrounding structures if not correctly contained.

High tensile strength and tearing strength

Excellent seepage control, seepage prevention and moisture proof performance

Excellent chemical resistance

High strength, anti puncture

High friction coefficient, excellent wear resistance

Excellent UV resistance

Stable low temperature resistance to brittleness

Anti-aging and anticorrosion

Easy to deploy efficiently

Cost saving

With their superior performance and adaptability, our composite geomembranes liners have gained recognition for their reliability and effectiveness in diverse sectors. Whether it’s environmental protection, infrastructure development, or agricultural projects, our liners offer a durable and efficient solution for maintaining integrity, preventing leaks, and enhancing overall project success.

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

Installation Tools for the Composite Geomembrane Liner Greenland Provide

Installation Tools for the Composite Geomembrane Liner Greenland Provide

|

|

|

|

Gromembranes Welding Machine |

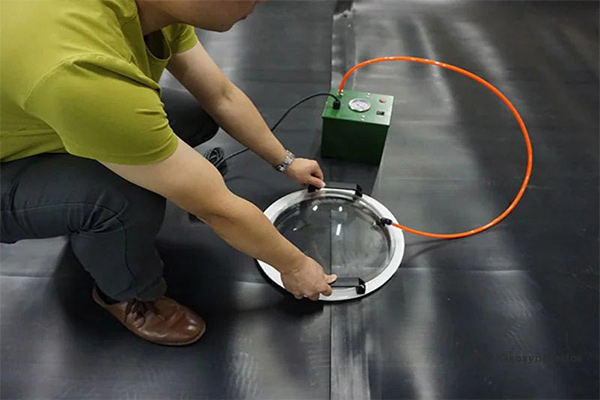

Air Pressure Testing Equipment |

Geomembrane Liner Leakage Detectors |

For the welding quality control of Composite Geomembrane Liner, we usually use geomembrane liner leakage detectors, vacuum boxes, air pressure testing equipment and other equipment to perform quality control on the surface and welds of the geomembrane.

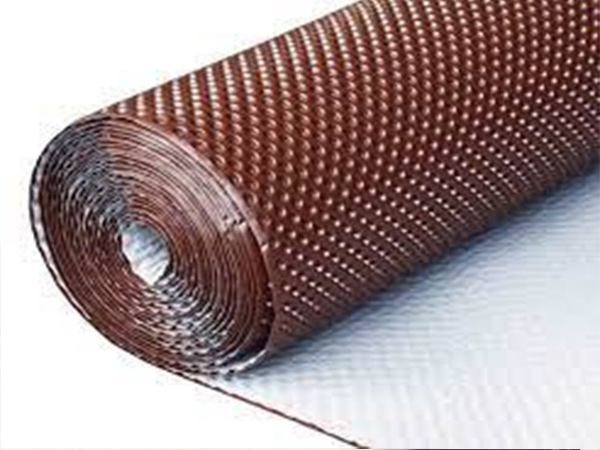

Packing of Composite Geomembrane Liner

Packing of Composite Geomembrane Liner

|

|

|

Packaged by the Woven bag |

Width: 2-8m, Lenght: 50-100m/Roll |

Width 1.0-8.0 meters; Length 50.0 – 200 meters

*We can manufacture the products in accordance with custom specifications or specific design criteria.

Please Contact us to Get More Details and Composite Geomembrane Liner Solutions, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Specifications of Different Composite Geomembrane Liner

Specifications of Different Composite Geomembrane Liner

Technical Specifications of Staple Fiber Geotextile Composite Geomembrane (GB/T17642-2008)

| Item | Indicators | ||||||||

| Specifications | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | Notes | |

| Breaking strength kN/m | 5.0 | 7.5 | 10.0 | 12.0 | 14.0 | 16.0 | 18.0 | Vertical and horizontal | |

| Elongation at break % | 30~100 | Vertical and horizontal | |||||||

| CBR Bursting strength kN ≥ | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | 2.8 | 3.0 | ||

| Tearing strength kN ≥ | 0.15 | 0.25 | 0.32 | 0.4 | 0.48 | 0.56 | 0.62 | Vertical and horizontal | |

| Peel strength N/cm | 6 | ||||||||

| Vertical permeability coefficient | According to the design contract requirements | ||||||||

| Item | Film thickness/mm | ||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1.0 | ||

| Resistance to static water pressure /Mpa≥ | One cloth one film | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 |

| Two cloths one film | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.4 | 1.6 | 1.8 | |

ASTM Standard for Filament Geotextile Composite Geomembrane

| Item | Index | ||||||||

| Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH200 |

| Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 2.00 mm |

| Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

| Tensile Properties | ||||||

| Yield strength | ASTM D6693 | 7 kN/m | 11 kN/m | 15 kN/m | 22 kN/m | 29 kN/m |

| Break strength | Type IV | 13 kN/m | 20 kN/m | 27 kN/m | 40 kN/m | 53 kN/m |

| Yield elongation | - | 12% | 12% | 12% | 12% | 12% |

| Break elongation | - | 700% | 700% | 700% | 700% | 700% |

| Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 249 N |

| Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 640 N |

| Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

| Carbon Black Content | ASTM D1603 | 2.0% | 2.0% | 2.0% | 2.0% | 2.0% |

| Carbon Black Dispersion | ASTM D5596 | For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 | ||||

| Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min, | 100 min, |

| UV Resistance High Pressure OIT retained after 1600hrs |

ASTM D5885 | 50% | 50% | 50% | 50% | 50% |

| Dimensions | ||||||

| Roll Width (m) | - | 7 | 7 | 7 | 7 | 7 |

| Roll Length (m) | - | 420 | 280 | 210 | 140 | 105 |

❖The Other Specifications and Standards of the Composite Geomembrane Liner are not listed here, please contact to get it now.

Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

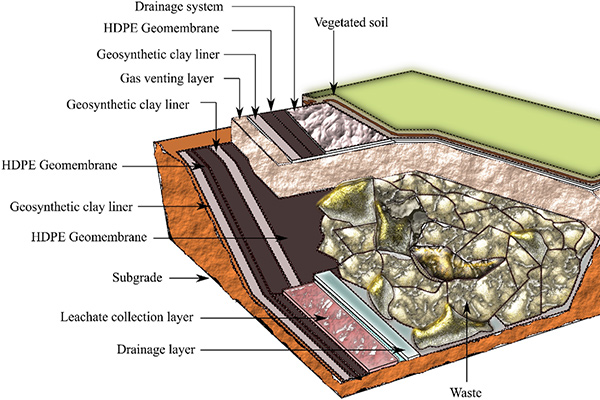

Applications of Composite Geomembrane Liner

Applications of Composite Geomembrane Liner

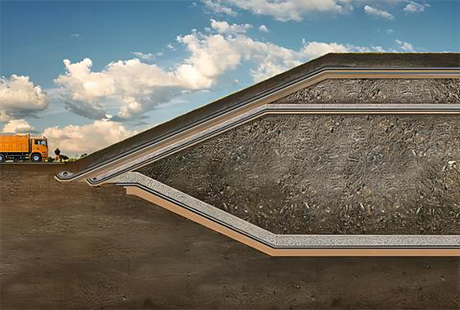

Our composite geomembrane liners find extensive use in a range of industries and projects. They are commonly employed in landfills to prevent leakage and contamination, and in wastewater treatment facilities to ensure effective containment. The liners are also utilized in road construction to enhance stability and durability, in aquaculture for pond lining and water containment, and in landscape and agriculture applications to control erosion and manage water resources effectively.

1. Composite geomembrane is suitable for water conservancy. Such as anti-seepage, plugging, reinforcement of dams of rivers, lakes, and reservoirs, anti-seepage of canals, vertical core walls, slope protection, etc.

2. Composite geomembrane can be used for environmental protection and sanitation. Such as landfills, sewage treatment plants, power plant conditioning pools, industrial, hospital solid waste, etc.

3. Composite geomembrane can be used in gardens, artificial lakes, rivers, reservoirs, pond bottoms of golf courses, slope protection, green lawns, etc.

4. Composite geomembrane can also be used for municipal engineering, subway, underground engineering of buildings, planting roofs, seepage prevention of roof gardens, and sewage pipes.

5. Composite geomembrane is suitable for mining, washing tank, heap leaching tank, ash dump, dissolution tank, sedimentation tank, storage yard, tailings bottom lining anti-seepage, etc.

6. Petrochemical, chemical plants, refineries, oil storage tanks, seepage prevention, chemical reaction tanks, sedimentation tank linings, secondary linings, etc. can still use composite geomembrane.

7. The composite geomembrane is also used in aquaculture, intensive, factory farming ponds, fish ponds, lining of shrimp ponds, sea cucumber circle slope protection, and other fields.

8. Salt industry, salt field crystallization pond, brine pond cover, salt film, salt pond plastic film.

9. Composite geomembrane is also used in agriculture, reservoirs, drinking water pools, storage ponds, and anti-seepage irrigation systems.

10.Transportation facilities, foundation reinforcement of highways, and seepage prevention of culverts can be constructed with a composite geomembrane.

|

|

|

Composite Geomembrane Liner for Construction of Artificial Lake |

Composite Geomembrane Liner Liners for Dam |

|

|

|

Composite Geomembrane Liner for Isolation of Sewage& Landfill |

Composite Geomembrane Liner for Aquaculture |

|

|

|

Composite Geomembrane Liner for Mining |

Composite Geomembrane Liner for Agriculture And Farming Pond |

Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Composite Geomembrane Liner

-

- Below are the detailed information of Composite Geomembrane Liner for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST of Data Sheet now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- Woven Geotextile Composite Geomembrane

DownLoad

- Short Fiber Geotextile Composite Geomembrane

DownLoad

- Filament Geotextile Composite Geomembrane

DownLoad

Documents Download of Composite Geomembrane Liner

Documents Download of Composite Geomembrane Liner

Other CUSTOMIZED Composite Geomembrane Liner have not been shown on above chart, please CONTACT US for more information

Please Contact us to Get More Geomembrane Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.