Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

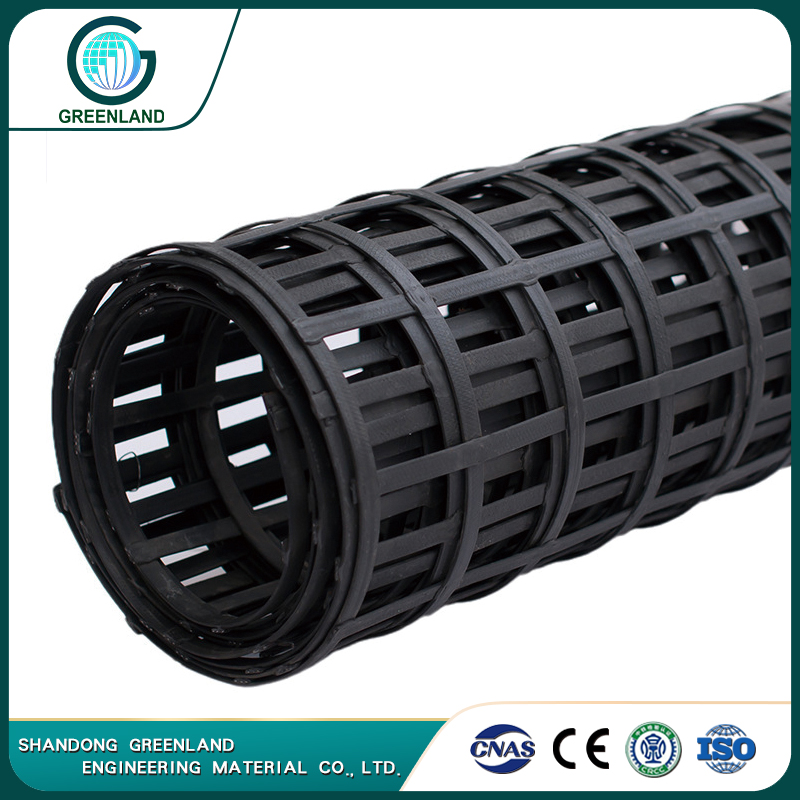

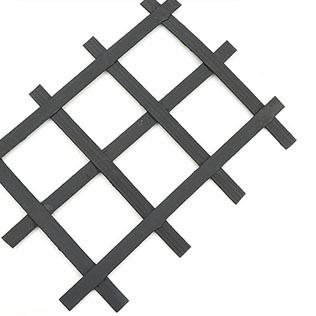

Welding Steel Plastic Geogrid

- 1.Width:1-6m

- 2.Length:50-100m

- 3.Material:HDPE,PP,Steel Plastic

- 4.Standards:ASTM

- 5.Mesh Size(mm):12.7*12.7mm,25.4*25.4mm

- 6.Delivery time:stock or 5-10 days after order confirmation

- 7.Packing:Roll Package

- 8.MOQ:Trial order is acceptable

- 9.Free Sample

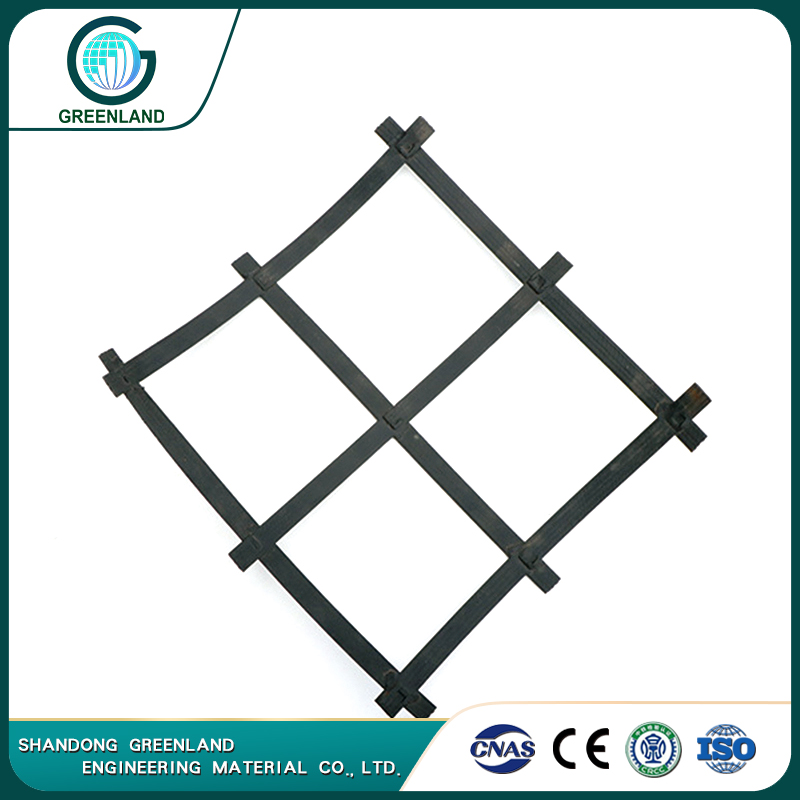

Steel-plastic geogrid is a mesh structure made of high-strength steel wire and polyethylene as the main materials, adding other additives, and forming high-strength tensile strips through melt extrusion according to the process, and then arranged vertically and horizontally at a certain distance and then welded. Most often, this product is used to strengthen the foundation of roads, thereby reducing the cost of construction materials and preventing cracks and ruts due to the handling of the road surface.

Quick Details of Welding Steel Plastic Geogrid

Quick Details of Welding Steel Plastic Geogrid

| Products details information | |

| Product name | Welding Steel Plastic Geogrid |

| Brand | Greenland (OEM is available) |

| Model No. | Biaxial Geogrid |

| Raw material | HDPE ,PP,Steel Plastic |

| Types | Welding |

| Mesh Size | 80*80mm,or as Request |

| Application | Stabilisation and Reinforcement |

| Color | Black and other colors |

| Standards | ASTM,ISO,JT/T 1432.1-2022 |

| Welding Tools | Hot air welding gun,roller welding machine |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of Welding Steel Plastic Geogrid

Description of Welding Steel Plastic Geogrid

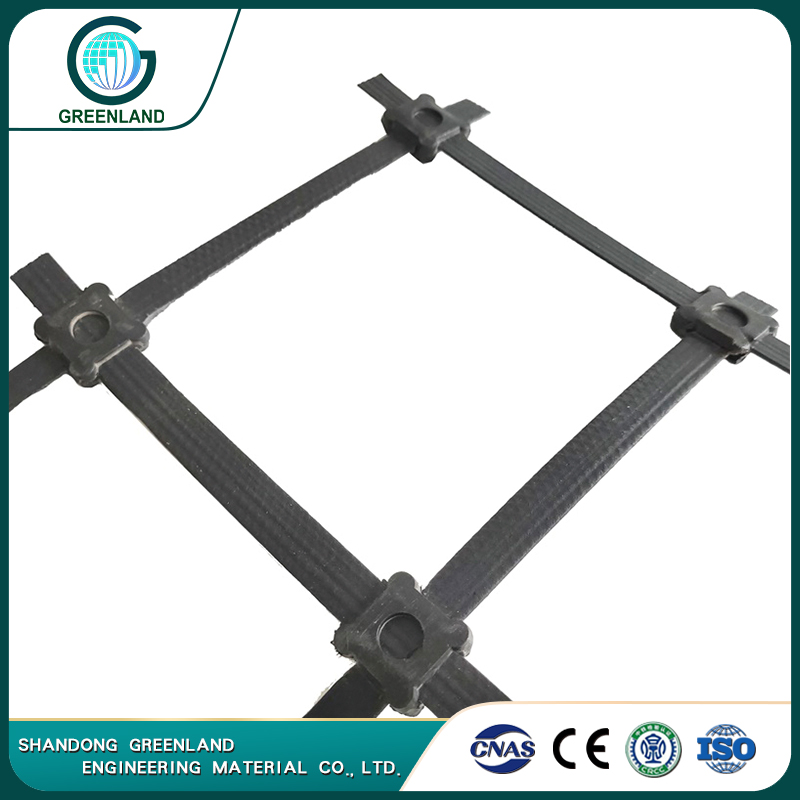

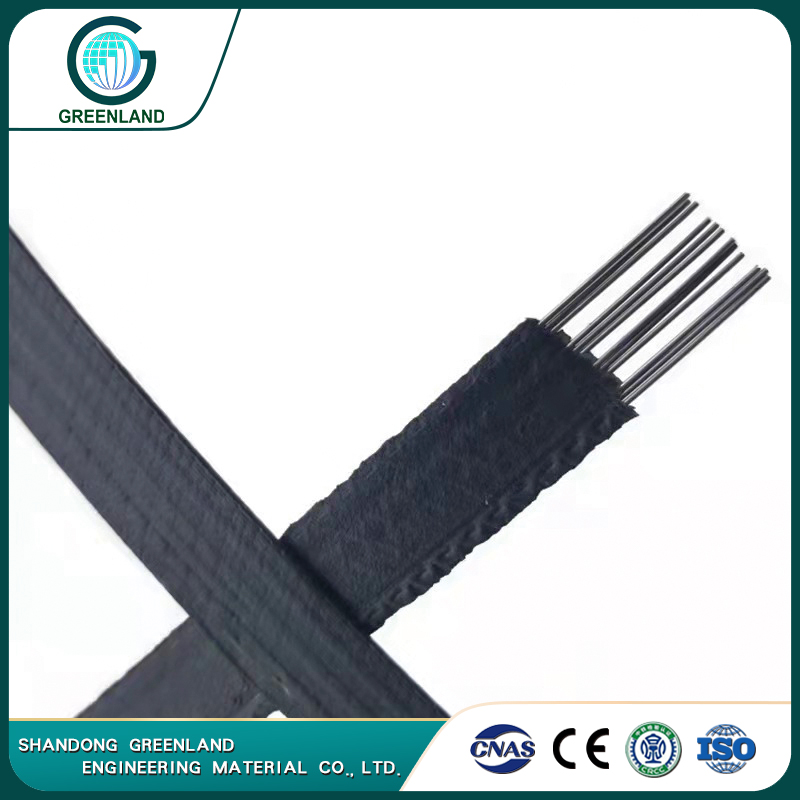

The welding steel plastic geogrid uses high tensile steel wire(or other fiber) specially handled and polyethylene (P.E) with other assistants. Then squeeze it out and make it become composite high-strength anti-pull belt and the horizontally using this single belt and welding the joint using a special welding technology to molding is reinforcement geogrid

|

|

|

| Steel plastic bonding | High strength | Low creep |

|

|

|

| Source Factory | customized | High Quality |

Benefits of Welding Steel Plastic Geogrid

Benefits of Welding Steel Plastic Geogrid

Welding Steel Plastic Geogrid has great friction with soil, and the contact area of Geogrid and soil reaches more than 20%-50%. Under low strain, it can produce extremely high tensile modulus. The synergistic action of the rib to the rib has a great locking effect on the soil.With polypropylene as the main material, adding anti aging agent and other auxiliaries, through extruding and drawing forming, it becomes a high strength refined strip. It is arranged in a certain distance and vertically and horizontally, and the welding point is welded by special reinforcement bonding. It is formed as a PP Welding Geogrid.

- 1.High strength, small creep, adaptable to various environmental soils.

- 2.It can effectively improve the interlocking and interlocking effect of the reinforced bearing surface, and enhance the bearing capacity and stability of the foundation.

- 3.The steel wires of the longitudinal and transverse ribs of the steel-plastic geogrid are woven into a mesh, and the outer wrapping layer is formed at one time. The steel wires and the outer wrapping layer can coordinately function, and the elongation at failure is very low (not more than 3%).

- 4.The width of the steel-plastic grating can reach 6 meters, achieving efficient and economical reinforcement effect.

- 5. The high-density polyethylene used in the steel-plastic grille can ensure that: it will not be corroded by acid, alkali, salt solution or oil under normal temperature conditions; it will not be dissolved by water or invaded by microorganisms. At the same time, the polymer properties of polyethylene are sufficient to resist aging caused by ultraviolet radiation.

Please Contact us to Get More Details, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

Welding steel plastic geogrid is a mesh structure made of high-strength steel wire and polyethylene as the main materials, adding other additives, and forming high-strength tensile strips through melt extrusion according to the process, and then arranged vertically and horizontally at a certain distance and then welded. Most often, this product is used to strengthen the foundation of roads, thereby reducing the cost of construction materials and preventing cracks and ruts due to the handling of the road surface.

| Welding Steel Plastic Geogrid | ||||||||||||

| Item | Ultimate tensile strength per extended meter-KN/m | Elongation at break % | Ultimate tensile strength per linear meter after 100 freeze-thaw cycles KN/m | Per linear meter after 100 freeze-thaw cycles Elongation at break % | mesh size mm | Frost Resistance Indicator ℃ | Adhesion, solder joints Limit peel force N | |||||

| NO. | Longitudinal | Horizontal | Longitudinal | Horizontal | Longitudinal | Horizontal | Longitudinal | Horizontal | Longitudinal | Horizontal | ||

| BWGEO30-30 | 30 | 30 | ≤3 | ≤3 | 30 | 30 | ≤3 | ≤3 | 232 | 232 | -35 | ≥100 |

| BWGEO40-40 | 40 | 40 | ≤3 | ≤3 | 40 | 40 | ≤3 | ≤3 | 149 | 149 | -35 | ≥100 |

| BWGEO50-50(A) | 50 | 50 | ≤3 | ≤3 | 50 | 50 | ≤3 | ≤3 | 220 | 220 | -35 | ≥100 |

| BWGEO50-50(B) | 50 | 50 | ≤3 | ≤3 | 50 | 50 | ≤3 | ≤3 | 125 | 125 | -35 | ≥100 |

| BWGEO60-60(A) | 60 | 60 | ≤3 | ≤3 | 60 | 60 | ≤3 | ≤3 | 170 | 170 | -35 | ≥100 |

| BWGEO60-60(B) | 60 | 60 | ≤3 | ≤3 | 60 | 60 | ≤3 | ≤3 | 107 | 107 | -35 | ≥100 |

| BWGEO70-70 | 70 | 70 | ≤3 | ≤3 | 70 | 70 | ≤3 | ≤3 | 137 | 137 | -35 | ≥100 |

| BWGEO80-80 | 80 | 80 | ≤3 | ≤3 | 80 | 80 | ≤3 | ≤3 | 113 | 113 | -35 | ≥100 |

| BWGEO100-100 | 100 | 100 | ≤3 | ≤3 | 100 | 100 | ≤3 | ≤3 | 95 | 95 | -35 | ≥100 |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Welded steel-plastic geogrids can be widely used in highways, railways, embankments, bridge abutments, construction access roads, docks, revetments, flood control embankments, dams, tidal flat management, cargo yards, slag yards, airports, sports fields, environmentally friendly buildings, and soft soil foundation reinforcement , retaining walls, slope protection and road surface resistance and other civil engineering projects.

❖Welding Steel Plastic Geogrid for Reinforcement Soil Foundation

1. It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2. It is used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by lock contraction;

3. It is used in road expansion and improvement project and crack caused by old combination position and uneven sedimentation;

4. It is used in soft soil base reinforcement treatment, is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength;

5. It is used for prevention contraction crack caused by new rode semi-rigid base layer, and reinforcing and preventing road surface crack.

|

|

| Geogrid for Reinforcement of soft soil foundation in slag yard | Geogrid For Reinforcement of soft soil foundation for dams |

|

|

| Geogrid For Reinforcement of railway soft soil foundation | Geogrid For Reinforcement of Highway Soft Soil Foundation |

Please Contact us to Get More Projects Cases, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

-

-

- Below are the specification of Welding steel plastic geogrid for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- 10.welding steel plastic geogrid

DownLoad

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

☎Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

-

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.