Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

Plastic Extrusion Welding Gun

-

- 1.Input Voltage:230 V

- 2.Frequency:50/60 H

- 3.Hot air temperature:3400 W

- 4.Hot air temperatur:20-620℃

- 5.Certification:CE

- 6.Delivery time:stock or 5-10 days after order confirmation

This plastic extrusion welding gun is the first in China to provide bipolar independent heating of the base metal and welding rod, digital temperature control display, 360-degree rotatable welding tip, and motor cold start protection. It uses a Japanese Hikoki electric drill as the extrusion motor. It has a compact body, easy operation, stable performance and can be continuously welded. It is suitable for welding PE, PP, PVDF and other hot-melt plastics.

The plastic extrusion welding gun includes three series:Dual heated extrusion welding machine,Single heating extrusion welding machine and Particle extrusion welding machine.

Dual heated extrusion welding machine:LST600A/LST600B/LST600C/LST610A/LST610B/LST610C

Single heating extrusion welding machine:LST600E/LST600F/LST610E

Particle extrusion welding machine:LST620

Quick Details of Warp Knitted Polyester grid Composite Geotextile

Quick Details of Warp Knitted Polyester grid Composite Geotextile

| Products details information | |

| Product name | Warp Knitted Polyester grid Composite Geotextile |

| Brand | Greenland (OEM is available) |

| Model No. | Sewed or Glued Available |

| Raw material | HDPE |

| Application | Reinforcement, Drainage, Tear Resistance |

| Mesh Size | 20*20mm,40*40mm,50*50mm |

| Standards | ASTM,ISO |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | More than 5 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of Plastic Extrusion Welding Gun

Description of Plastic Extrusion Welding Gun

Geomembrane extrusion welding gun is a tool specifically used for welding geomembranes and other thermoplastic materials. Its working principle is to use hot air to preheat the surface of the welding material, and then melt and extrude the welding material through an extrusion device, so as to fuse with the surface of the welded material and achieve welding.

Structural composition: Hot air preheating section: used to preheat the surface of welding materials, ensuring that the materials can be uniformly heated during the welding process and avoiding welding defects caused by uneven temperature.

Extrusion device: including single screw extruder, electrode feeder, etc., responsible for melting and extruding solder.

Control system: used to adjust parameters such as hot air temperature and extrusion speed to ensure stable and controllable welding process.

|

|

|

| LST610E | LST620 | LST600F |

|

|

|

| LST610B | LST600E | Heat-resiatant rutting |

Benefits of Plastic Extrusion Welding Gun

Benefits of Plastic Extrusion Welding Gun

-

- ◆1.Simple operation: advanced feedback type control system. Combined with excellent materials, the control is more accurate and the service life is long.

- ◆2.Ultra-high power: The high-power hot wedge heats faster, has high heating efficiency, and the welding is firm and smooth, improving work efficiency.

- ◆3.Bipolar independent heating system: The feed heating system and the hot air heating system are independently separated to ensure that the melting temperatures of the base metal and the welding rod are consistent, thereby achieving the best welding effect.

- ◆4.Digital temperature control display system: Microcomputer chip control, easy and intuitive operation, strong protection function.

- ◆5.360-degree rotating welding nozzle: The hot air welding nozzle can be adjusted 360 degrees to meet different application needs.

- ◆6.Cold start protection: If the preset melting temperature is not reached, the extrusion motor will automatically shut down, effectively avoiding damage to the equipment caused by misoperation.

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

Please Contact us to Get More Details, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

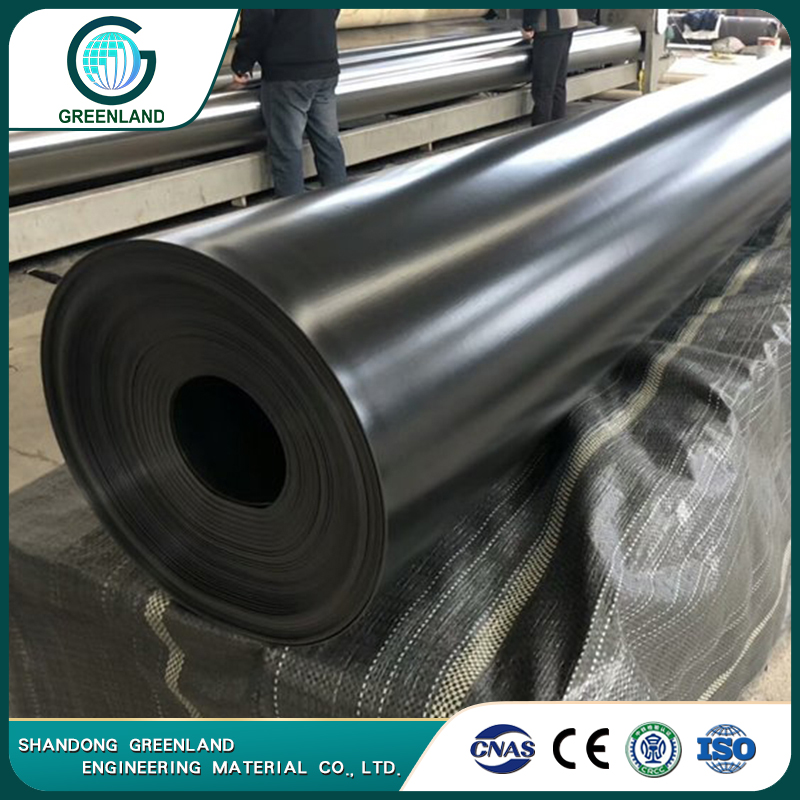

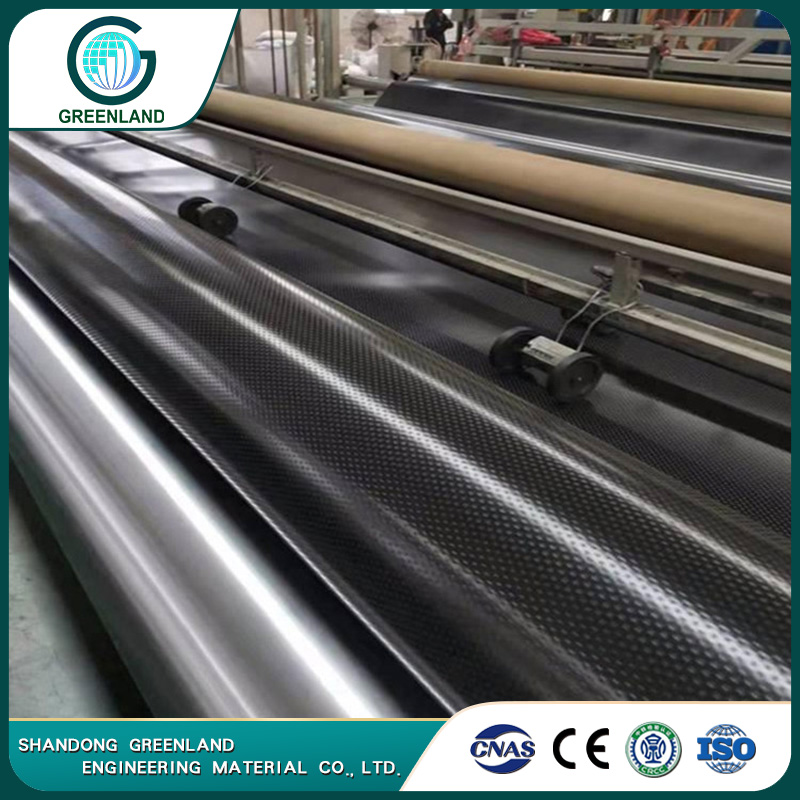

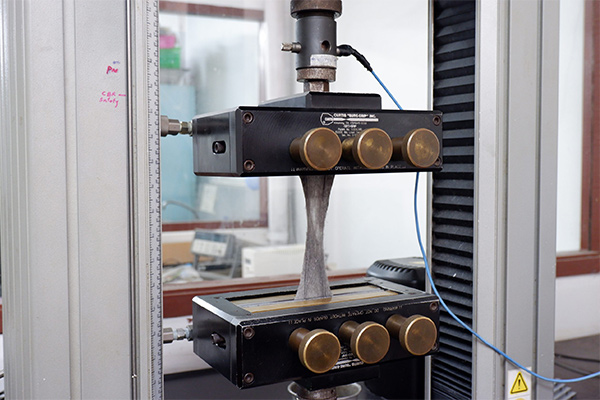

Warp knitted polyester grid composite geotextile is a new geotechnical material made of polyester fiber (or synthetic fiber) as reinforcing material and compounded with broken needle-punched non-woven geotextile. Warp knitted polyester grid composite geotextile can be used for reinforcement, isolation and protection, and has good water gathering and water conduction functions. Because its solid matrix and pores are continuous phases and have a porous filtering effect, it is a multifunctional geocomposite material and is also a high-level base material for geocomposite applications in the world today.

| Warp Knitted Polyester grid Composite Geotextile | |||||||

| Categories | Model | Cracking-intensity (KN/m) | Break elongation ratio (%) | Mesh Size (mm*mm) | Breadth (m) | ||

| Longitudinal | Crosswise | Longitudinal | Crosswise | ||||

| High Strength Polyester Fiber Composite Geotextile | GPN25/150 | ≥25 | ≥25 | ≤20 | ≤20 | 12~50 | 2~6 |

| GPN50/150 | ≥50 | ≥50 | ≤20 | ≤20 | 12~50 | 2~6 | |

| GPN80/150 | ≥80 | ≥80 | ≤20 | ≤20 | 12~50 | 2~6 | |

| High Strength Polyester Fiber Geogrid Composite Geotextile | GPM25/150 | ≥25 | ≥25 | ≤20 | ≤20 | 12~50 | 2~6 |

| GPM50/150 | ≥50 | ≥50 | ≤20 | ≤20 | 12~50 | 2~6 | |

| GPM80/150 | ≥80 | ≥80 | ≤20 | ≤20 | 12~50 | 2~6 | |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Plastic Extrusion Welding Gun widely used in Production, splicing and repair of environmental protection equipment, anti-corrosion equipment, electroplating equipment, acid and alkali resistant equipment, carriage linings, plastic water tanks, plastic pipes, plastic containers, plastic sheets, plastic film materials and other fields.

Welding of PE, PP, PVC, PVDF and other hot-melt plastics.

❖Application of Plastic Extrusion Welding Gun

|

|

| Geogrid Composite Geotextile For Reinforcement of expressway | Geogrid Composite Geotextile For Renovation of old roads |

|

|

| Geogrid Composite Geotextile For Soft soil foundation reinforcement | Geogrid Composite Geotextile For Railway subgrade reinforcement |

Please Contact us to Get More Projects Cases, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

- Below are the Plastic Extrusion Welding Gun specification for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- plastic extrusion welding gun

DownLoad

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.