Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

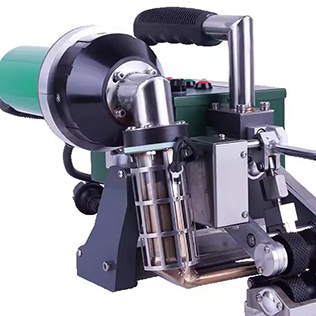

Geomembranes Welding Machine

-

-

- 1. Input Voltage: 230V/120 V

- 2. Frequency: 50/60 Hz

- 3. Weld Pressure: 100-1000 N

- 4. Standards: CE

- 5. Model: 700, 800/800D/810/820, 900/900D, GM1/GM2

- 6. Guarranty: 1 year

- 7. Packing: 50×37×40 cm or depend on product size

- 8. MOQ: Trial order is acceptable

-

The main welding objects of geomembranes welding machines include HDPE, LDPE, PVC, EVA, ECB geomembranes, and composite membranes. The mechatronics integration design of the welding machine is small in size and light in weight, with strong operability for on-site operation. It features double seam lap welding, high temperature control accuracy, high welding strength, good sealing effect, and can automatically crawl, achieving automatic welding of tilting, verticality, and inversion. Our models are mainly divided into 900/900D, 800/800D/810/820, 700, and GM1/GM2.

Quick Details of Geomembranes Welding Machine

Quick Details of Geomembranes Welding Machine

| Products details information | |

| Product name | Geomembranes Welding Machine |

| Brand | Greenland (OEM is available) |

| Input Voltage | 230V/120 V |

| Frequency | 50/60 Hz |

| Weld Pressure | 100-1000 N |

| Model | 700, 800/800D/810/820, 900/900D, GM1/GM2 |

| Standards | CE |

| Application | Engineering in multiple fields such as tunnel waterproofing, underground anti-seepage, aquaculture, and sewage treatment. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Different Models of Geomembranes Welding Machine

Different Models of Geomembranes Welding Machine

900/900D: This welding machine adopts an advanced hot wedge structure, which has better heating efficiency and faster welding speed, making it particularly suitable for HDPE, LDPE, PVC, EVA, ECB and other membrane materials with a thickness of 1.0-3.0mm are used in waterproofing and anti-seepage engineering in fields such as water conservancy, aquaculture, landfill, chemical mining, sewage treatment, and roof construction.

800/800D/810/820: This welding machine is a hot wedge welding machine used for welding HDPE, LDPE, EVA, PVC, ECB, PP thermoplastic materials. It is used in waterproofing projects such as tunnels, subways, water conservancy, agriculture, solid waste landfill sites, chemical engineering, sewage treatment, and roofs.

GM1/GM2: This welding machine adopts a hot wedge structure, which has high power, high speed, and high pressure, and can weld hot melt materials with a thickness of 0.2-2.0mm. This machine is specifically designed for waterproofing projects such as water conservancy, aquaculture, landfill, chemical mining, sewage treatment, and roof construction.

700: This welding machine adopts an advanced hot air heating system, which is small in size, light in weight, and fast in speed. Even in corrosive materials and harsh working environments, it can improve welding quality. This machine is specifically designed for waterproofing projects such as tunnels, subways, water conservancy, aquaculture, biogas plants, landfills, chemical mines, sewage treatment, and roof construction.

Though specific engineering and site conditions will determine which type of geomembrane welding machine is used for a particular application.

|

|

|

| Geomembranes Welding Machine-900 | Geomembranes Welding Machine-800 | Geomembranes Welding Machine-810 |

|

|

|

| Geomembranes Welding Machine-GM1 | Geomembranes Welding Machine-GM2 | Geomembranes Welding Machine-700 |

Benefits of Geomembranes Welding Machine

Benefits of Geomembranes Welding Machine

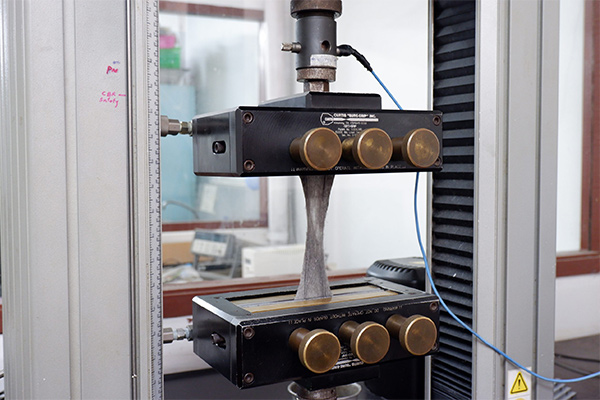

1. High fusion strength, The strength of the welding joint is basically the same as the strength of the raw material.

2. Environmental protection and energy saving,using electric heating fusion technology, the welding process is non-toxic, harmless, odorless and pollution-free.

3. Simple operation, only need to adjust the working temperature and the position of the welding head.

4. Wide scope of application, Geomembrane welding machine can be used to weld various types of membrane materials.

5. High reliability, It can perform multiple continuous operations and ensure normal operation in harsh environments.

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

Please Contact us to Get More Details, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

Specifications of Diifferent Model Geomembranes Welding Machine

Specifications of Diifferent Model Geomembranes Welding Machine

1. Heavy-Duty Geo Hot Wedge Welder - 900/900D

| Model | 900 | 900D |

| Input Voltage | 230 V/120 V | 230 V/120 V |

| Frequency | 50/60 Hz | 50/60 Hz |

| Power | 1800 W/1650 W | 1800 W/1650 W |

| Welding speed | 1-5 m/min | 1-5 m/min |

| Heating temperature | 50-450 ℃ | 50-450 ℃ |

| Weld pressure | 100-1000 N | 100-1000 N |

| Welding material thickness | 1.0 mm-3.0 mm (single layer film thickness) | 1.0 mm-3.0 mm (single layer film thickness) |

| Lap width | 12 cm | 12 cm |

| Weld width | 15 mm*2, cavity 15 mm | 15 mm*2, cavity 15 mm |

| Weld strength | ≥85 % base material (shear direction tensile strength) | ≥85 % base material (shear direction tensile strength) |

| Overall weight | 13.0 kg | 13.0 kg |

| Digital display function | Temperature display | Dual display of temperature and speed |

2. Geomembranes Welding Machine - 800/800D/810/820

| Model | 800 | 800D | 810 | 820 |

| Input Voltage | 230 V/120 V | 230 V/120 V | 230 V/120 V | 230 V/120 V |

| Frequency | 50/60 Hz | 50/60 Hz | 50/60 Hz | 50/60 Hz |

| Power | 800 W/1100 W | 800 W/1100 W | 800 W/1100 W | 800 W/1100 W |

| Welding speed | 0.5-5 m/min | 0.5-5 m/min | 1-5 m/min | 0.5-5 m/min |

| Heating temperature | 50-450 ℃ | 50-450 ℃ | 50-450 ℃ | 50-450 ℃ |

| Welding material thickness |

0.2 mm-1.5 mm (single layer film thickness) |

0.2 mm-1.5 mm (single layer film thickness) |

0.2 mm-1.5 mm (single layer film thickness) |

0.2 mm-1.5 mm (single layer film thickness) |

| Lap width | 10 cm | 10 cm | 15 cm | 20 cm |

| Weld width | 12.5 mm*2, cavity 12 mm | 12.5 mm*2, cavity 12 mm | 12.5 mm*2, cavity 12 mm | 12.5 mm*2, cavity 12 mm |

| Weld strength |

≥85 % base material (shear direction tensile strength) |

≥85 % base material (shear direction tensile strength) |

≥85 % base material (shear direction tensile strength) |

≥85 % base material (shear direction tensile strength) |

| Overall weight | 5.0 kg | 5.0 kg | 5.5 kg | 6.0 kg |

| Digital display function | Temperature display | Dual display of temperature and speed | Temperature display | Temperature display |

3. Geomembranes Welding Machine - GM1/GM2

| Model | GM1 | GM2 |

| Input Voltage | 230 V/120 V | 230 V/120 V |

| Frequency | 50/60 Hz | 50/60 Hz |

| Power | 1400 W | 600 W |

| Welding speed | 0.5-6 m/min | 0.5-5 m/min |

| Heating temperature | 50-450 ℃ | 50-450 ℃ |

| Welding material thickness | 0.2 mm-2 mm (single layer film thickness) | 0.2 mm-2 mm (single layer film thickness) |

| Lap width | 12 cm | 12 cm |

| Weld width | 15 mm*2, cavity 15 mm | 15 mm*2, cavity 15 mm |

| Weld strength | ≥85 % base material (shear direction tensile strength) | ≥85 % base material (shear direction tensile strength) |

| Overall weight | 9.0 kg | 7.5 kg |

| Film entry method | two-way membrane entry | unilateral same side membrane entry |

| Digital display function | Temperature display | Dual display of temperature and speed |

4. Geomembranes Welding Machine - 700

| Model | 700 |

| Input Voltage | 230 V/120 V |

| Frequency | 50/60 Hz |

| Power | 2800 W/2200 W |

| Welding speed | 0.5-3.5 m/min |

| Heating temperature | 50-620 ℃ |

| Weld pressure | 100-1000 N |

| Welding material thickness | 0.5 mm-2 mm (single layer film thickness) |

| Lap width | 16 cm |

| Weld width | 15 mm*2, cavity 15 mm |

| Weld strength | ≥85 % base material (shear direction tensile strength) |

| Overall weight | 7.5 kg |

| Digital display function | Dual display of temperature and speed |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

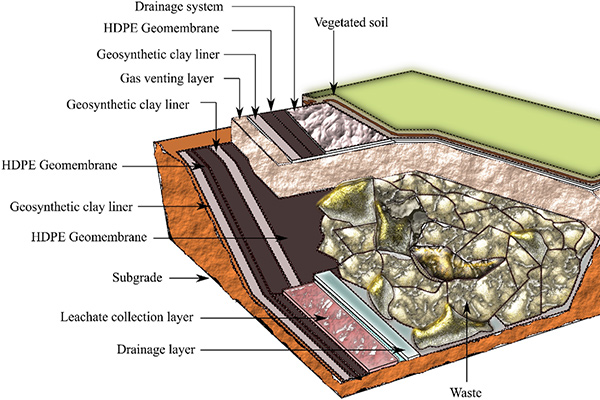

Applications of Geomembranes Welding Machine

Applications of Geomembranes Welding Machine

Geomembranes welding machine is suitable for materials such as HDPE, LDPE, PVC, ECB, EVA, PP, etc.

Landfill anti-seepage project

Sewage disposal anti-seepage project

Lake anti-seepage project

Water conservancy anti-seepage project

Tunnel anti-seepage project

Minerals place anti-seepage project

Cultivation pond anti-seepage project

Roofing waterproofing project

|

|

|

Geomembranes Welding Machine for landfill Project |

Geomembranes Welding Machine for Tunnel Project |

|

|

|

Geomembranes Welding Machine for Tailings project |

Geomembranes Welding Machine for Cultivation Pond Project |

Please Contact us to Get More Projects Cases, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

Geomembranes Welding Machine

-

- Below are the detailed information of Geomembranes Welding Machine for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST of Geomembrane Liners now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- Geomembranes Welding Machine

DownLoad

Documents Download of Geomembranes Welding Machine

Documents Download of Geomembranes Welding Machine

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.