Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

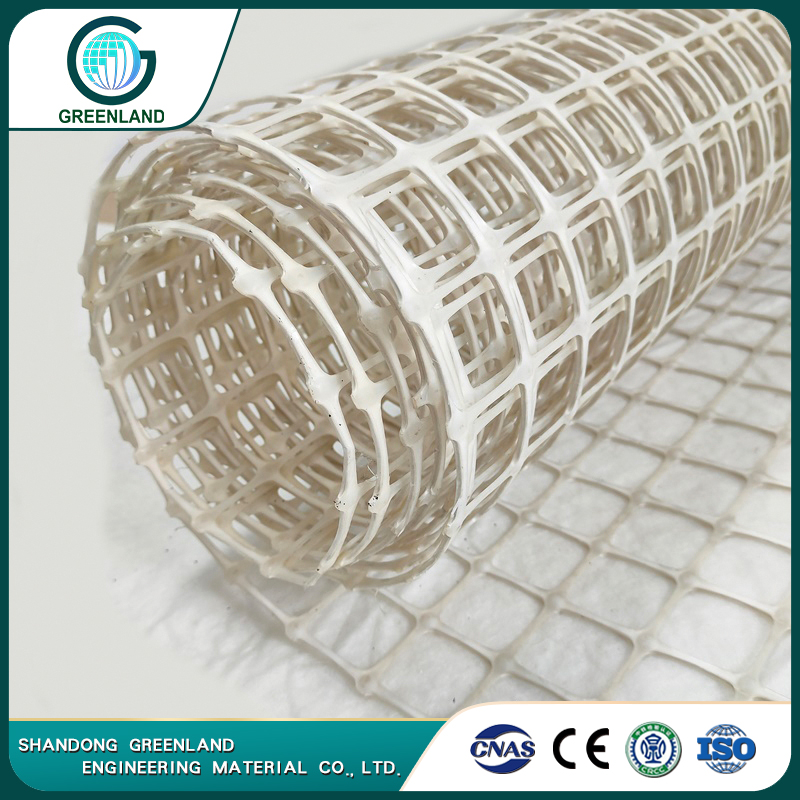

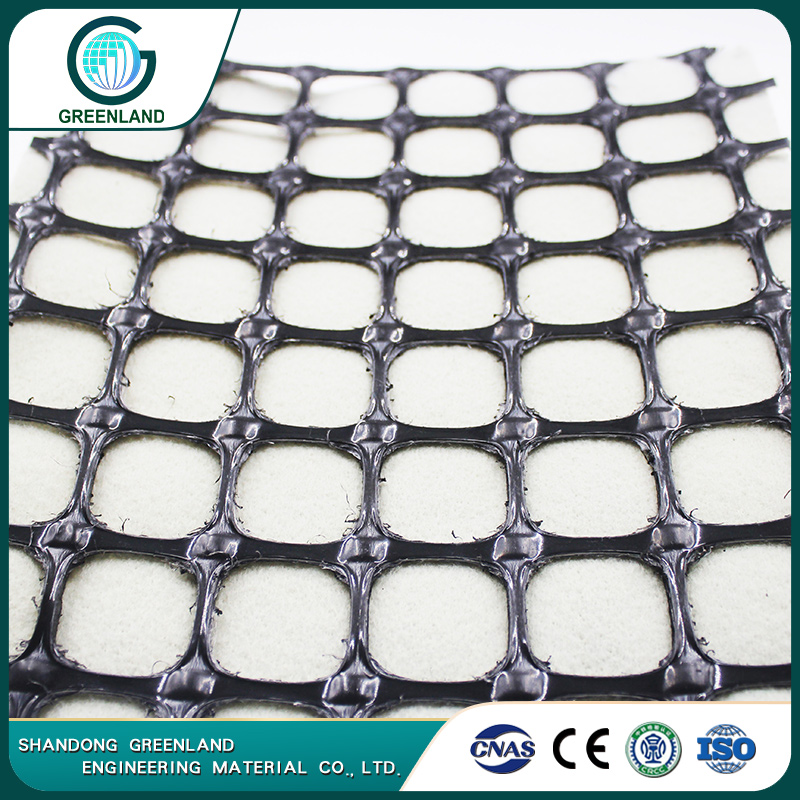

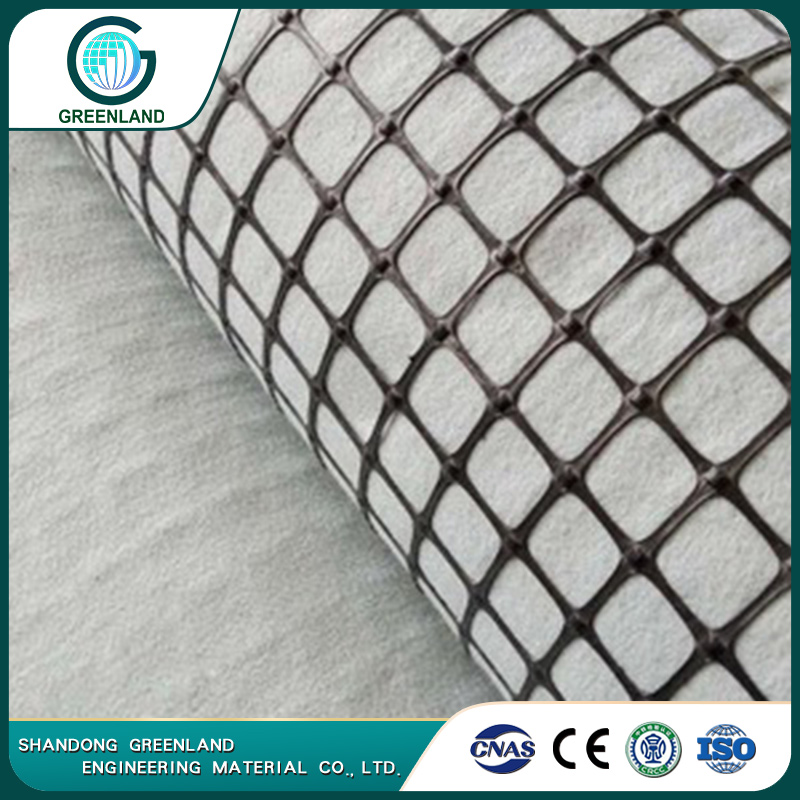

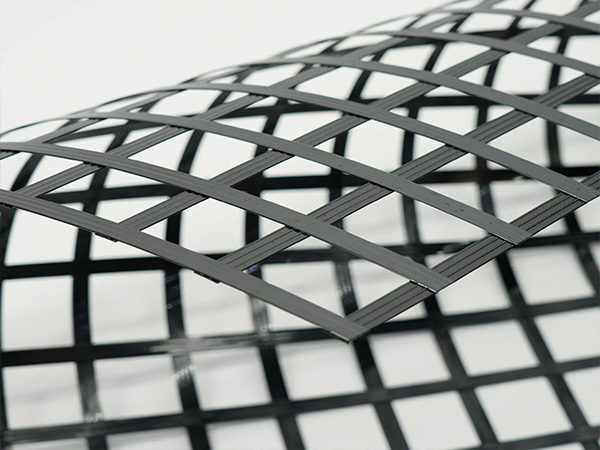

Geogrids Mesh

- 1.Tensile Strength: 5-350Kn/m

- 2.Width: Max. 8M

- 3.Raw Material: HDPE, PP, LLDPE, PVC,PET(Polyster), Steel Plastic, Glassfiber…

- 4.Standard: ASTM, GRI, ISO, GB/T

- 5.Geogrids Series: Biaxial Geogrids, Uniaxial Geogrids, Triaxial Geogrids, Combigrid

- 6.Production Technique: Knitted, Integrally formed, Precision knitted, Bonded, Woven, Extruded

- 7.Delivery: Stock for regular item, 5-10 Days for Production

- 8.Packing: 50-100m length/roll, Customized

- 9.MOQ: Trial order is acceptable

- 10.Free Sample Available

Geogrids are a class of geosynthetic materials made of polymer materials with widespread transportation, infrastructure, and structural applications. Geogrids are now routinely used in soil stabilization applications ranging from reinforcing walls to soil reinforcement below grade or embankments with increased potential for remote-sensing applications.

Quick Details of Geogrids Mesh

Quick Details of Geogrids Mesh

| Products details information | |

| Product name | PE/PP/PET Geogrids Mesh |

| Brand | Greenland (OEM is available) |

| ensile Strength | T5-350Kn/m |

| Raw material | HDPE, PP, LLDPE, PVC,PET(Polyster), Steel Plastic, Glassfiber... |

| Application | stabilisation or reinforcement function, to enhance the performance of soils, eparation between soil and aggregate layers and are used widely in civil engineering applications. |

| Color | Black, White, other colors |

| Standards | GRI, ASTM, ISO, GB/T |

| Tools | Geotextile Cutting Tool, Bulldozers and Excavators, Anchors and retaining clamps, Seam material,Measuring Tools, Personal Protective Equipment, Road roller, Hand tools... |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

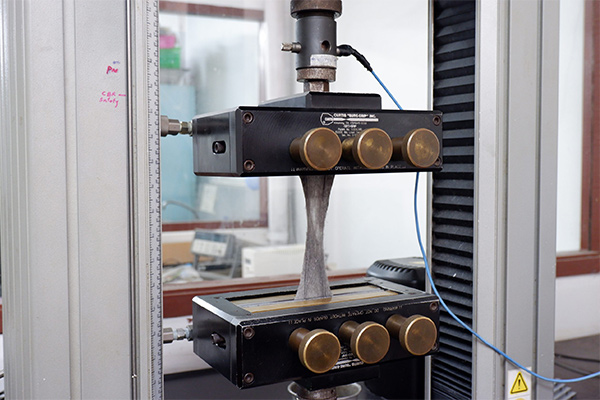

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

A geogrid is geosynthetic material used to reinforce soils and similar materials. Commonly used for soil reinforcement applications such as retaining walls, steepened slopes, bridge abutments, embankments, embankments over soft soils and waste containment, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Compared to soil, geogrids are strong in tension. This fact allows them to transfer forces to a larger area of soil than would otherwise be the case. Greenland offers a number of geogrids to meet any specific requirement, learn more about our geogrids here:

The Most Commonly Used Type Of Geogrid Category

The Most Commonly Used Type Of Geogrid Category

❖Types of Geogrids on on Pattern

|

|

|

|||

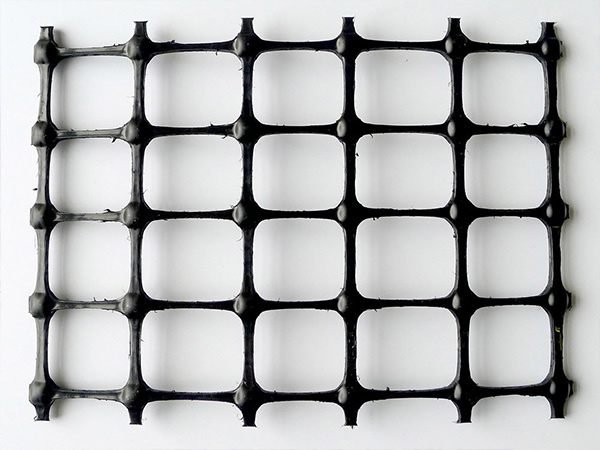

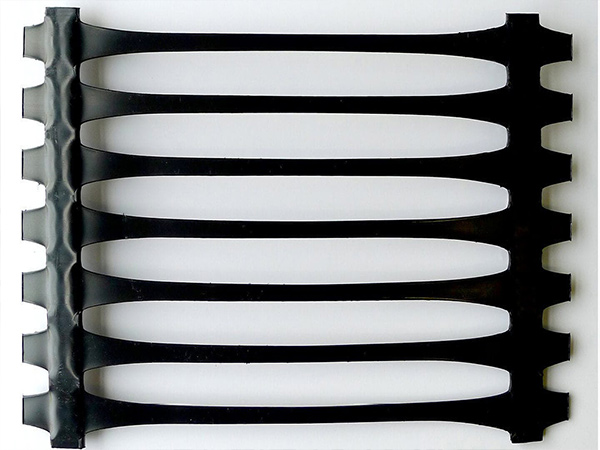

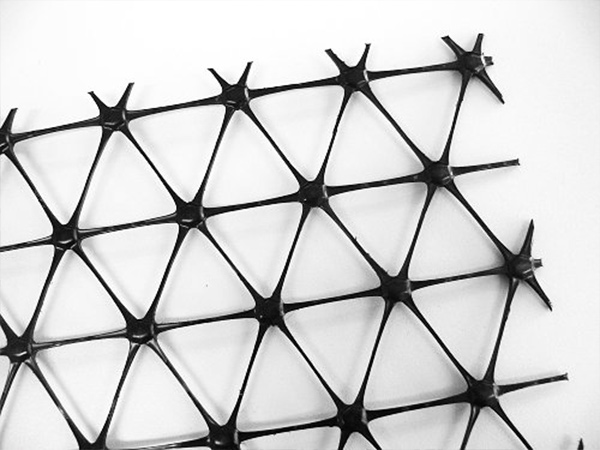

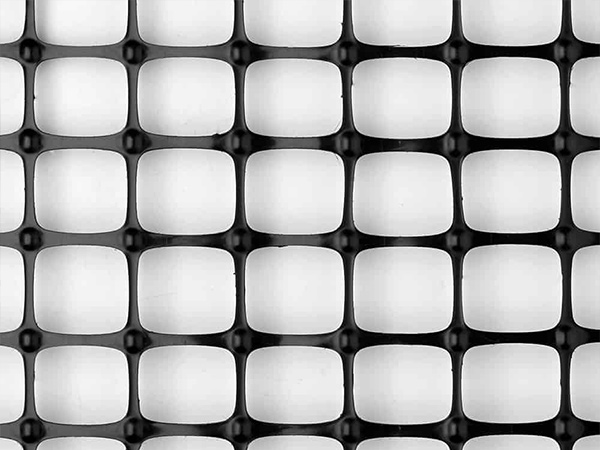

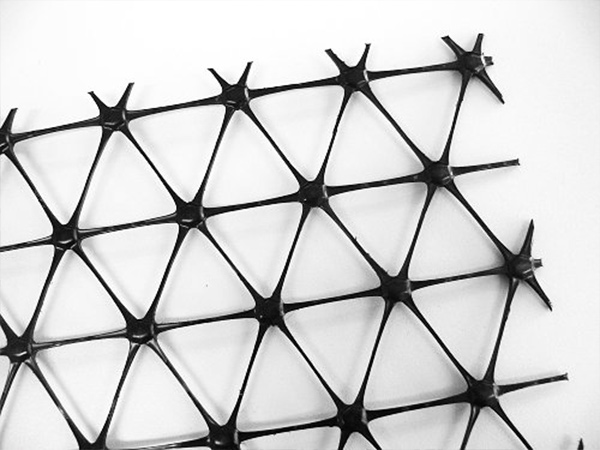

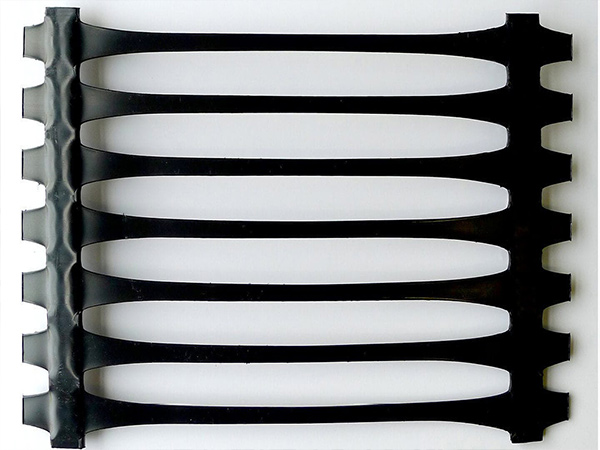

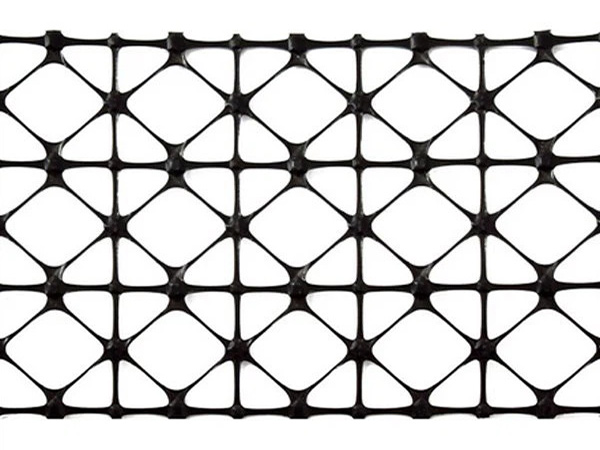

| ❖Biaxial Geogrids | ❖Uniaxial Geogrids | ❖Triaxial – TTX Geogrids |

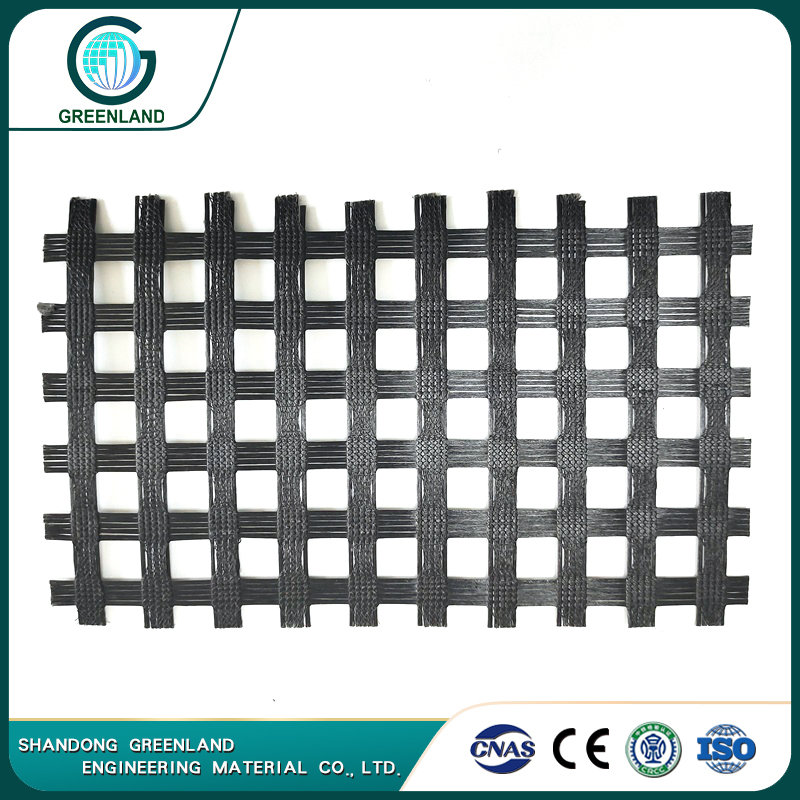

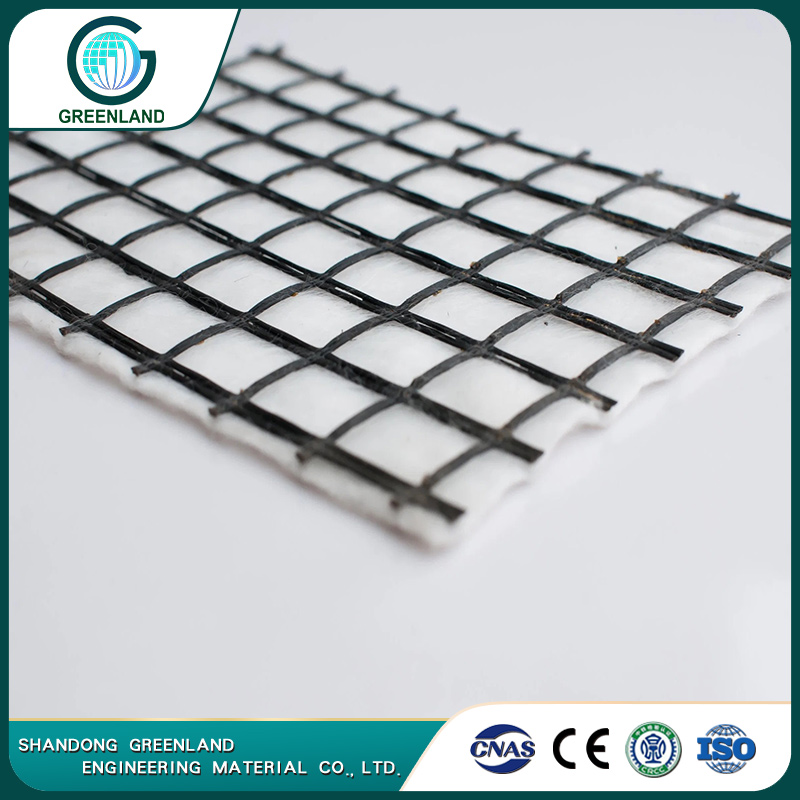

Uniaxial geogrids, also sometimes referred to as “one-way” or “one-directional” geogrids, are geogrids that are only strong in one direction, even though they may look very similar to a biaxial geogrid. Uniaxial geogrids are typically used in scenarios where soils only require reinforcement in one direction – almost always in retaining walls or slope reinforcement scenarios.

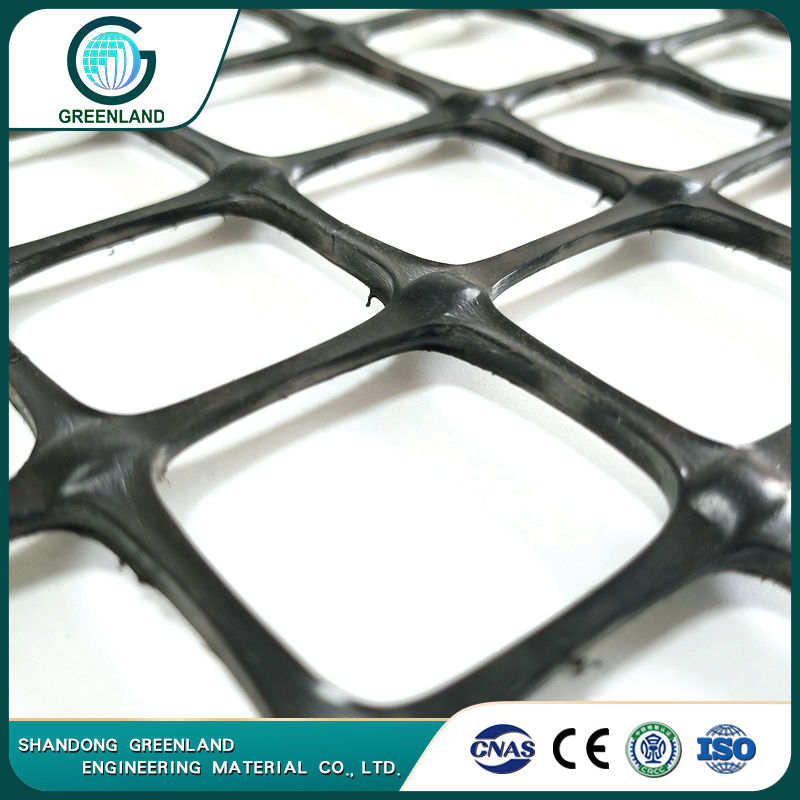

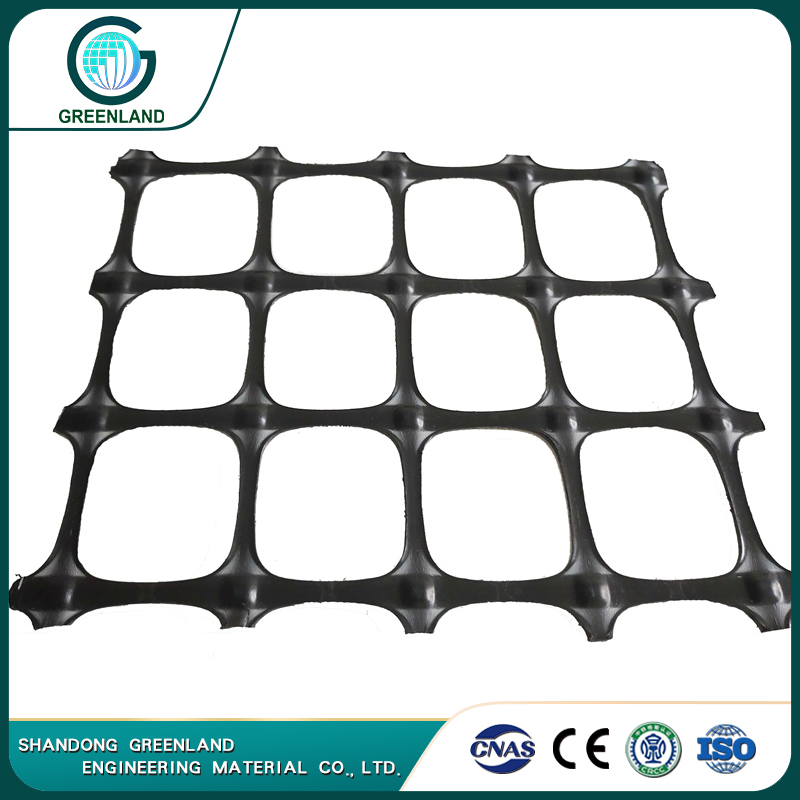

Biaxial geogrids are sometimes referred to as “two-way” or “bi-directional” geogrids and are equally strong in two directions. This type of grid can be used in retaining wall construction, and can be rolled out along the retaining wall blocks, provided the roll width is wide enough to cover the geogrid design width. It’s typical use, however, is in roadway construction (including gravel driveways) and foundation improvement applications.

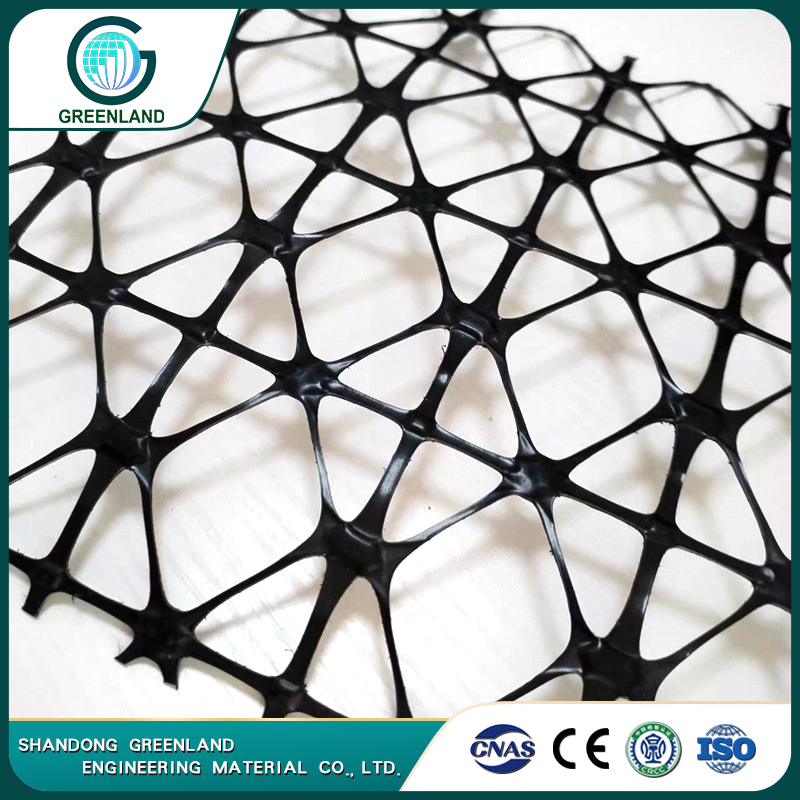

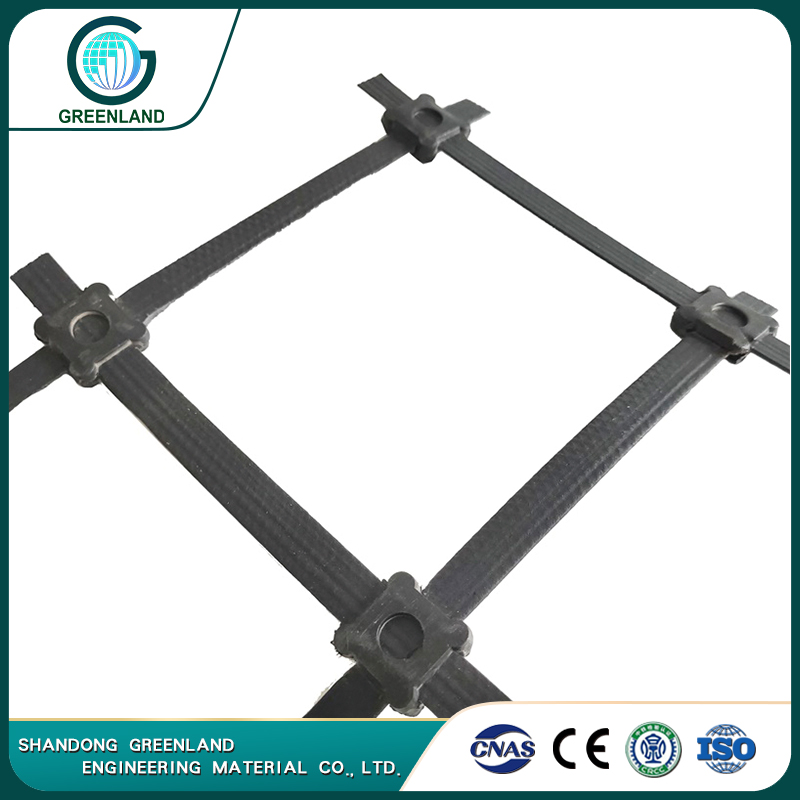

Triangular (or triaxial) geogrids are increasingly popular due to the more quasiisotropic behaviors compared to uniaxial and biaxial grids. The triangular geogrid reinforced base course over a weak subgrade was tested against an unreinforced soil sample under cyclic loading.It was found that the soil reinforced with triangular geogrid achieved a higher traffic benefit ratio. An increase in the traffic benefit ratio was observed at the heavy-duty geogrid. Moreover, the maximum vertical stress and the permanent deformations in the soil decreased with the triangular geogrid reinforcement. The stresses were more uniformly distributed among the soil and geogrid.

❖Types of Geogrids on Manufacturer Process Technical

Extruded geogrids

Woven geogrids

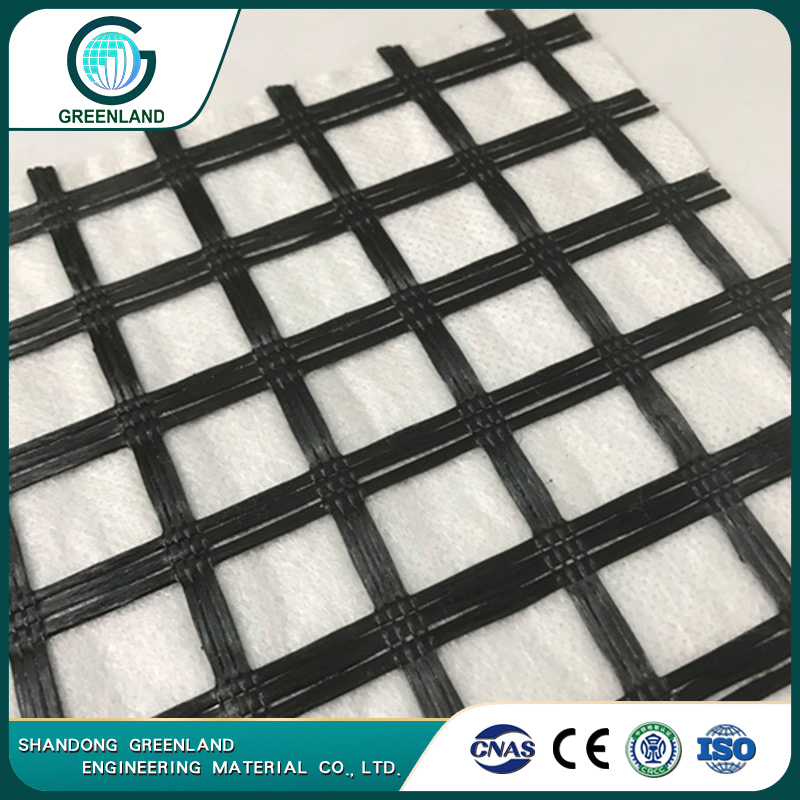

Bonded geogrids

Welding Steel Plastic Geogrids

Other Types of Geogrids

❖Types of Geogrids on Manufacturer Process Technical

Fiberglass geogrids

PET Geogrids

Warp Knitted Fiberglass Geogrids

HDPE Uniaxial Geogrid

Geocomposite Geogrid

Fiberglass geogrids is a new supreme material used for reinforcing road surfaces and bases, it is produced of fiberglass filament, and shielded with special solutions and High longitudinal and horizontal intensity, moderate elongation rate, anti-alkaline, and aging resistance, broadly used in the asphalt road surface, concrete road surface, and reinforcing road infrastructure.

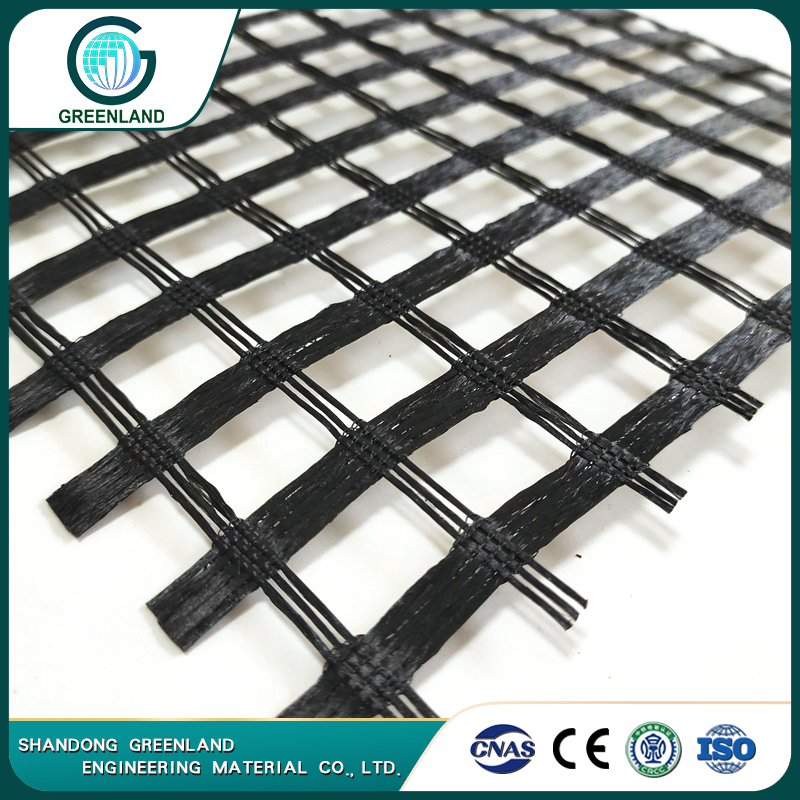

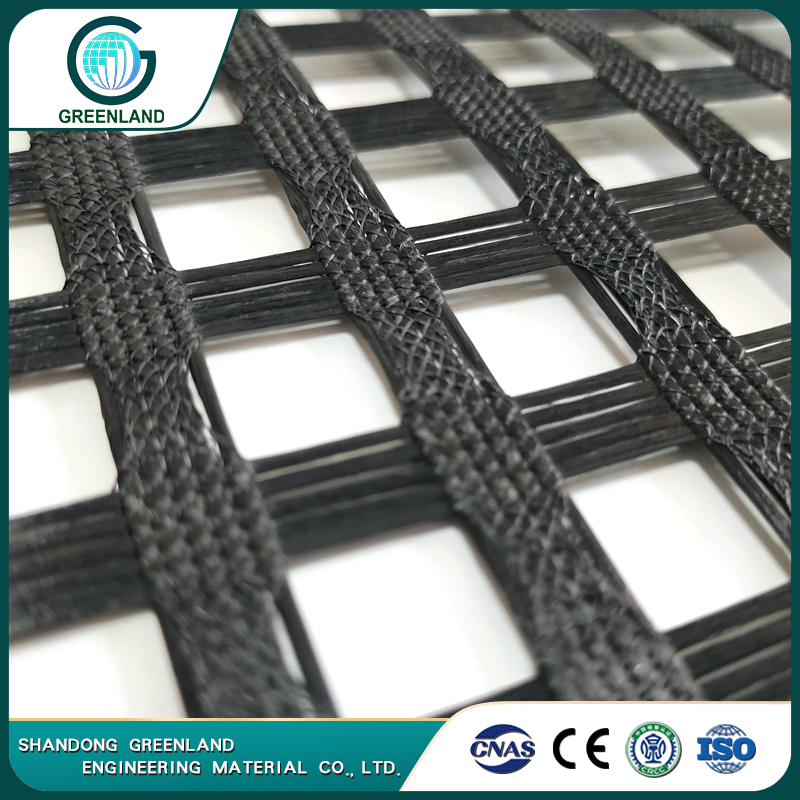

PET Geogrids, terylene geogrids is an afresh material for reinforcing road infrastructures; it is produced of terylene filament, and shielded with a special solution and High longitudinal and horizontal strength, moderate elongation rate, anti-alkaline, and aging resistance.

Warp Knitted Fiberglass Geogrids is woven by great Tensile Modulus fiberglass filament as the raw material is protected with adhesive.

Different Kinds of Geogrids Mesh

Different Kinds of Geogrids Mesh

|

|

|

| Woven Geogrids | Extruded PP/PET/PE Geogrids | Bonded Triaxial Geogrids |

|

|

|

| Uniaxially Stretched PP Geogrids | Four-way Tensile Geogrids | High Strength Steel Plastic Geogrids |

❖Please Contact US and Get a Solutions of the Geomembrane Now.

Benefits of Geogrids Mesh

Benefits of Geogrids Mesh

The geogrids provide good resistance against chemicals, bacteria and tensile strength. This is also a sustainable, environmentally friendly material. Furthermore, geogrids are extremely easy to install and store, as it is supplied in a compressed, accordion-folded shape.

1. Ease of Construction, The Geogrid can be installed in any weather conditions. This makes it more demanding.

2. Land Optimization:This method of Geogrid installation in soils makes an unsuitable area suitable for preparing it to meet desired properties for construction. Geogrid thus helps in proper land utilization.

3. Geogrid promotes soil stabilization

4. A higher strength soil mass is obtained

5. Higher load bearing capacity

6. It is a good remedy to retain soil from erosion

7. No requirement of mortar. The material is implemented dry.

8. Geogrids are flexible in nature. They are known for their versatility.

9. Geogrids have high durability reducing maintenance cost. They are highly resistant against environmental influences

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

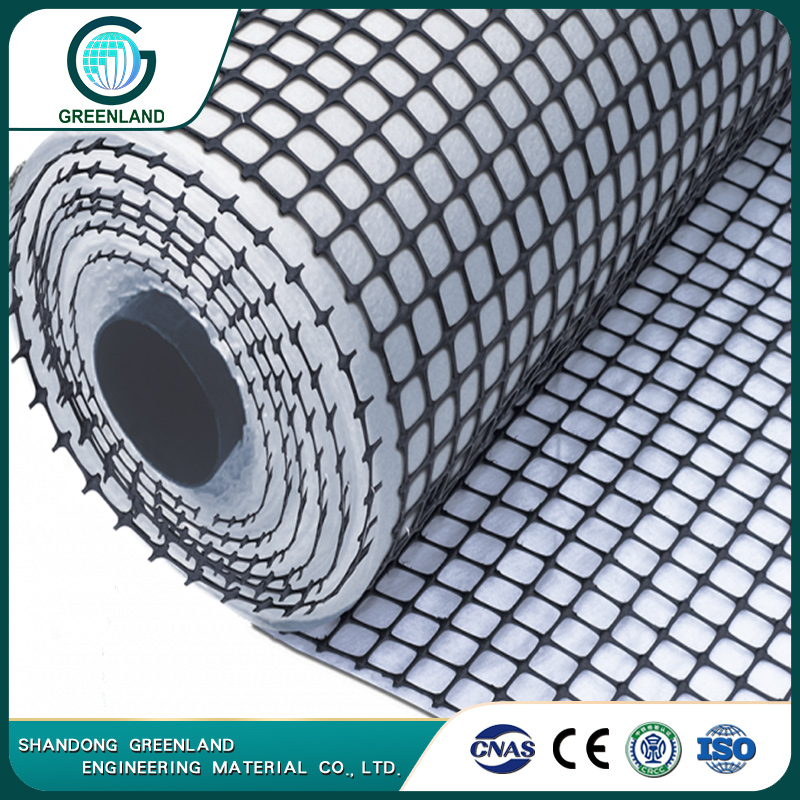

Packing of Geogrids

Packing of Geogrids

|

|

|

Packaged by the Woven bag |

Width: 2-8m, Lenght: 50-100m/Roll |

☎Please Contact us to Get More Details and Geogrids Solutions, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Biaxially stretched plastic geogrids have great tensile strength in both longitudinal and transverse directions. This structure can provide a more effective chain system for bearing and diffusing forces in soil, suitable for large-scale permanent bearing foundation reinforcement.

| Biaxially Stretched PP(Polypropylene) Geogrids | ||||||||||||||||||

| Specification | Test Method | BX1515 | BX2020 | BX2525 | BX3030 | BX4040 | BX1100 | BX1200 | BX3030L | |||||||||

| Index | Unit | MD | XMD | MD | XMD | MD | XMD | MD | XMD | MD | XMD | MD | XMD | MD | XMD | MD | XMD | |

| Ultimate Tensile strenth | D6637 | KN/m | 15 | 15 | 20 | 20 | 25 | 25 | 30 | 30 | 40 | 40 | 12.4 | 19 | 19.2 | 28.8 | 30 | 30 |

| Aperture Size | mm | 39 | 39 | 39 | 39 | 39 | 39 | 39 | 39 | 39 | 39 | 25 | 33 | 25 | 33 | 65 | 65 | |

| 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | 36 | |||||||||

| 33 | 33 | 33 | 33 | 33 | 33 | 33 | 33 | 33 | 33 | |||||||||

| 31 | 31 | 31 | 31 | 31 | 31 | 31 | 31 | 31 | 31 | |||||||||

| Minimum Rib Thickness | mm | 1 | 0.8 | 1.5 | 1.1 | 1.8 | 1.4 | 2.2 | 1.7 | 2.5 | 2 | 1 | 0.8 | 1.4 | 1.27 | 1.7 | 1.5 | |

| Tensile Strength @2%Strain | D6637 | KN/m | 6 | 6 | 7 | 7 | 9 | 9 | 11 | 11 | 15 | 15 | 4.1 | 6.6 | 6 | 9 | 11 | 11 |

| Tensile Strength @5%Strain | D6637 | KN/m | 11 | 11 | 13 | 13 | 17 | 17 | 21 | 21 | 27 | 27 | 8.5 | 13.4 | 11.8 | 19.6 | 21 | 21 |

| Junction Efficiency | % | 95 | 95 | 95 | 95 | 95 | 95 | 95 | 95 | |||||||||

| Flexural Stiffness | D7748 | mg-cm | 690,000 | 780,000 | 860,000 | 960,000 | 1,000,000 | 250,000 | 750,000 | 960,000 | ||||||||

| Aperture Stability | m-N/deg | 0.3 | 0.5 | 0.62 | 0.75 | 0.85 | 0.32 | 0.65 | 0.75 | |||||||||

| Resistance to InstallationDamage | %SC/%SW/%GP | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | 95/93/90 | |||||||||

| Resistance to Long TermDegradation | % | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |||||||||

| Resistance toUV Degradation | D4355 | % | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | ||||||||

| Minimum Cabon Black | % | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |||||||||

Uniaxially stretched PP geogrid is made of high molecular polymer, which is plasticized and extruded into sheets, punched, heated and then stretched longitudinally. It is laid in the soil, and through the interlocking and interlocking effects between the grid mesh and the soil, an efficient stress transmission mechanism is formed, so that the local load can be quickly and effectively spread to a large area of soil. This reduces local damage stress and improves the service life of the project.

| Specification | Unit | TGDG25 | TGDG35 | TGDG50 | TGDG80 | TGDG110 | TGDG120 | TGDG160 | TGDG200 | TGDG220 | TGDG260 | TGDG300 |

| Polymer | PP | |||||||||||

| Carbon Black |

% | 2 | ||||||||||

| Tenslle strength |

kN/m | 25 | 35 | 50 | 80 | 440 | 120 | 160 | 200 | 220 | 260 | 300 |

| Elongation | % | 11.5 | ||||||||||

| Tensile strength at 2%strain |

kN/m | 7 | 10 | 12 | 26 | 32 | 36 | 45 | 56 | 80.0 | 94 | 120 |

| Tensile strength at 5%strain |

kN/m | 14 | 22 | 28 | 48 | 64 | 72 | 90.0 | 112 | 156 | 185 | 220 |

| Width | m | 1 or 1.1 or 2.5 or 3 | ||||||||||

Mining Plastic Geogrid is made of polypropylene. It is produced through through several processes: extruding, punching, heating, longitudinal stretching and transverse stretching. It has a high tensile strength. After adding some percent of carbon black material, it makes the product good acid and alkali resistance, corrosion resistance and ageing resistance and durability. Mining Plastic Geogrid is widely used for Improving the bearing capacity of foundation, Preventing cracking and subsiding. It is an economic construction material which is convenient to construct, reducing cost and maintaining expense. Compared with uniaxial geogrid, PP/Plastic Biaxial Geogrid can provide longer service time, higher strength and nicer reinfrocement ability.

| Property | Test Method | TGSG | TGSG | TGSG | TGSG | TGSG | TGSG | |

| 15-15 | 20-20 | 30-30 | 40-40 | 50-50 | 60-60 | |||

| Ultimate tensile strength(1)(kN/m |

MD | 15 | 20 | 30 | 40 | 50 | 60 | |

| CD | 15 | 20 | 30 | 40 | 50 | 60 | ||

| Elongation a maximum load (%) |

MD | 13 | ||||||

| CD | 13 | |||||||

| Tensile strength at 2 %elongation (kN/m) |

MD | 5 | 7.5 | 10.5 | 14 | 18 | 27.5 | |

| CD | 5 | 7.5 | 10.5 | 14 | 18 | 27.5 | ||

| Tensile strength at 5 %elongatior (kN/m) |

MD | ASTM D 6637 | 7 | 14 | 21 | 28 | 35 | 48 |

| CD | 7 | 14 | 21 | 28 | 35 | 48 | ||

| Minimum Carbon Black |

% | ASTM D 4218 | 2 | |||||

☎Please Contact us to Get More Details About the Geogrids, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Applications of Geogrids Mesh

Applications of Geogrids Mesh

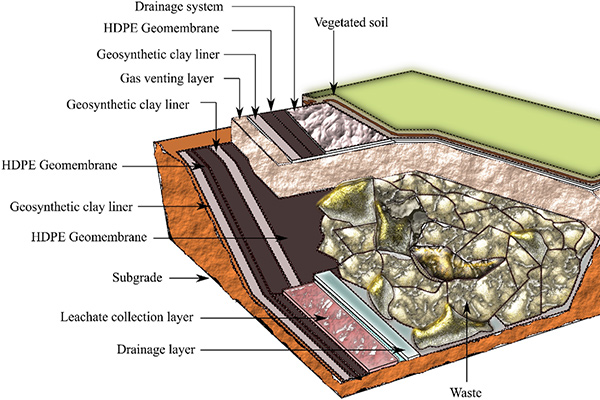

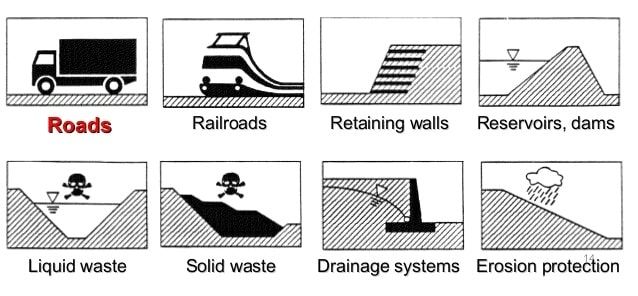

Geogrids have been greatly used for the construction of earth-sustained and earth-supported structures like mechanically stabilized earth (MSE) retaining walls, steep slopes, and further structures. Its application areas comprise.

❖1. Geogrids for pavements

Geogrids applications in pavement and roadway are made up of subgrade improvement, reinforcing the core course, sub-infrastructure, and surface courses. The outward displacement of railway ballast is apprehended and the settlement is shortened when they are reinforced with geogrids soft subgrade, the stiffer geogrids function better than flexible geogrids as the latter instantly reacts to the applied load.

❖2. Geogrids for retaining wall

Geogrids are accustomed to stabilizing the backfill in retaining walls. The stability of the earth retaining wall counts on the friction angle. Creep and stress relaxation properties influence the performance of geogrids in a retaining wall.

❖3. Geogrids for soil foundation

Both Uniaxial and Biaxial geogrids are typically used in foundation works. The main condition to attain good stability is the interlocking capacity of geogrids and aggregates.

❖4. Geogrids for slope stabilization

he geogrids reinforcement in slope prompts primarily the slope deformation and stability. The bearing capacity majorly depends on the length of the geogrids. To attain the best performance the aperture size should be closely equal to 0.2 times the width of the footing.

❖5. Geogrids for structural elements

In structural elements, the geogrids are used as further reinforcement and as shear reinforcement. To obtain good strength fibers such as polypropylene and steel are used. The geogrids reinforcement brings about high ultimate load-bearing capacity], enhanced energy absorption and reduced slippage, shear, and bond strength, lesser drying shrinkage, and shortened degradation rate.

|

|

|

Geogrids Mesh for Road Construction |

Geogrids Mesh for Raod Projects |

|

|

|

Geogrids Mesh for Expressway in Uganda |

Geogrids Mesh for Mining |

☎Please Contact us to Get More Details About the Geogrids, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

-

- Below are the detailed information of Geogrids Mesh for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST of Geomembrane Liners now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- Biaxially Stretched PP Geogrids

DownLoad - Biaxially Stretched HDPE Geogrids

DownLoad - Mining Plastic Geogrids

DownLoad - Uniaxial Stetched PP geogrid

DownLoad

Documents Download of Geogrids Mesh

Documents Download of Geogrids Mesh

Other CUSTOMIZED Geogrids Mesh have not been shown on above chart, please CONTACT US for more information

☎Please Contact us to Get More Geogrids Specifications, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.