Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

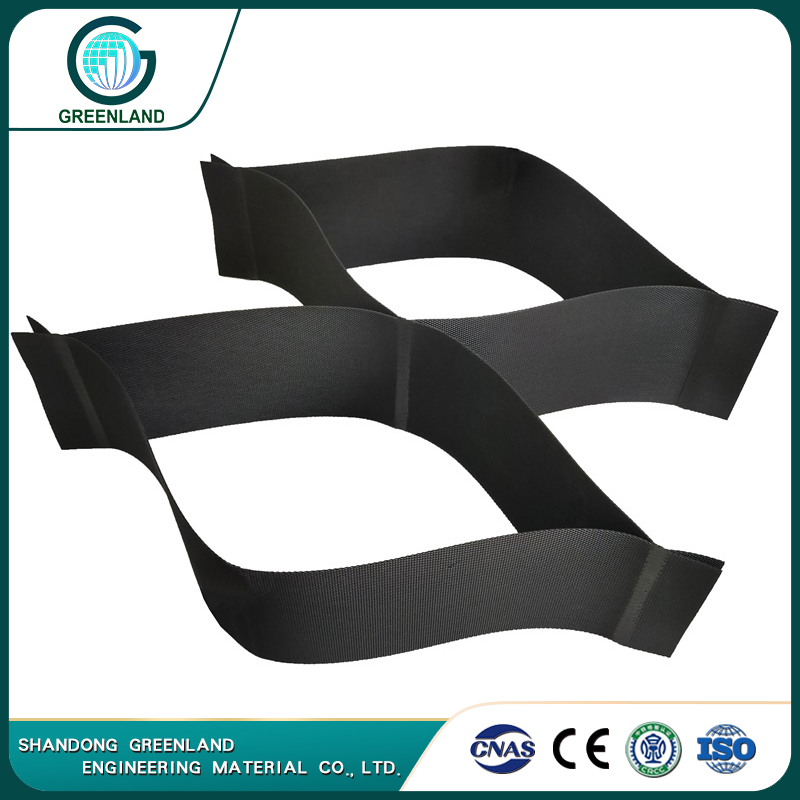

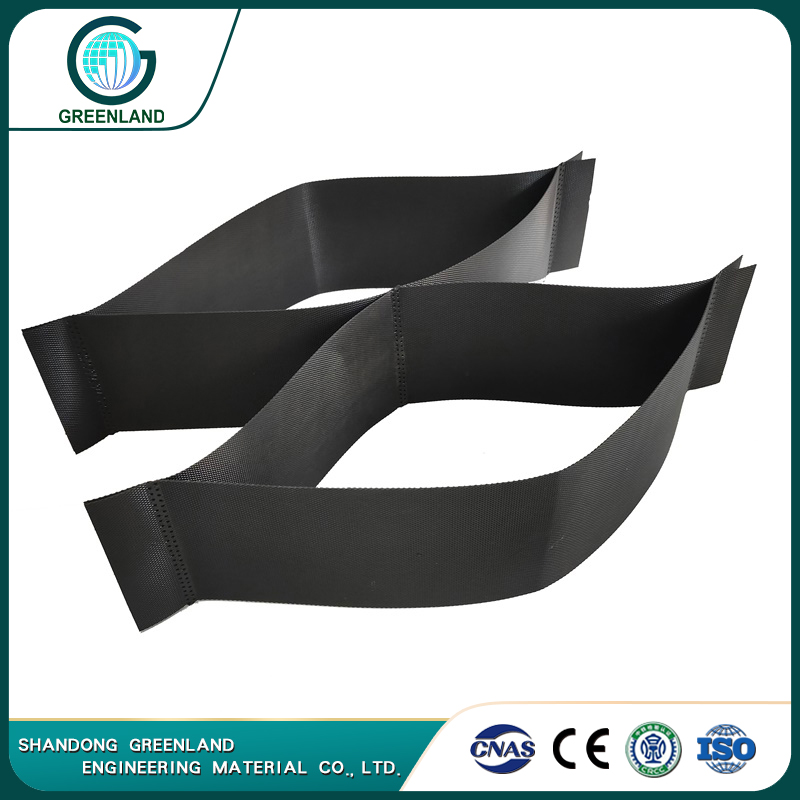

HDPE/PP Geocells

- 1.Cell size: 220-750mm, Customized

- 2.Sheet Thickness: 1-2.0mm

- 3.Raw Material: HDPE, PP…

- 4.Standard: ASTM, GRI, ISO, GB/T

- 5.Sheet Surface: Smooth、Textured、Perforated

- 6.Delivery: Stock for regular item, 5-10 Days for Production

- 7.Packing: 50-100m length/roll, Customized

- 8.MOQ: Trial order is acceptable

- 9.Free Sample Available

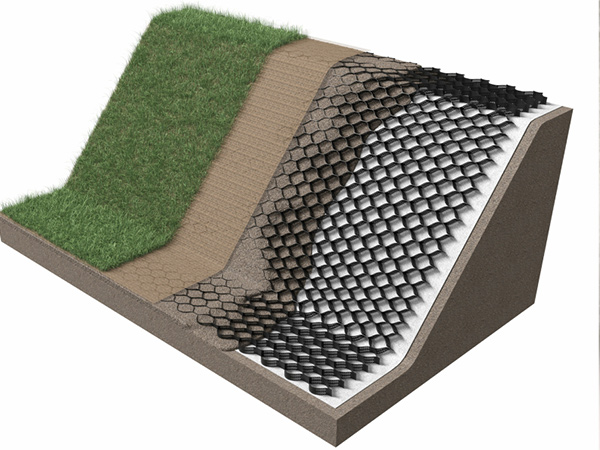

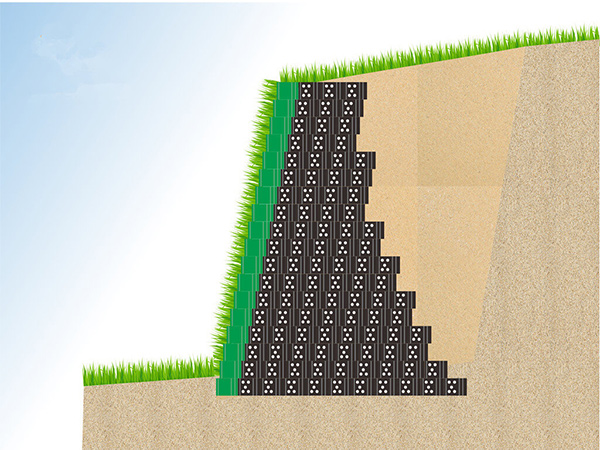

Geocell is a three-dimensional cellular structure that can be filled with soil, gravel, or other materials to stabilize steep slopes and prevent erosion. They are made of high-density polyethylene (HDPE) and have an open cellular structure that allows them to conform to the terrain.

Quick Details of HDPE/PP Geocells

Quick Details of HDPE/PP Geocells

| Products details information | |

| Product name | PE/PP/Geocells |

| Brand | Greenland (OEM is available) |

| Cell size | 220-750mm, Customized |

| Raw material | HDPE, PP... |

| Application | Civil engineering, landscaping, railways, roadways, slopes and walls, mining, coastal, ports, Ports & aviation... |

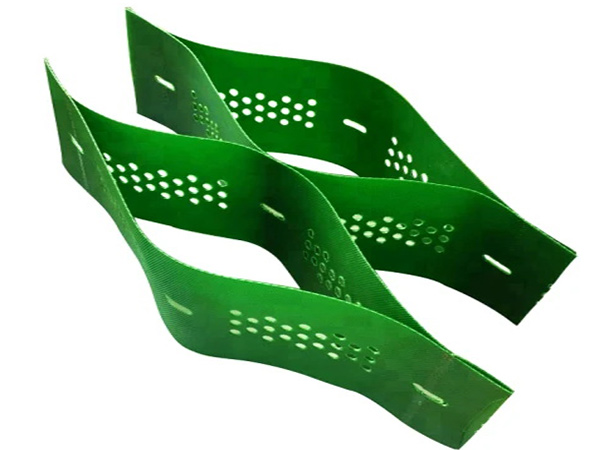

| Color | Black, White, other colors |

| Standards | GRI, ASTM, ISO, GB/T |

| Tools | Geotextile Cutting Tool, Bulldozers and Excavators, Anchors and retaining clamps, Seam material,Measuring Tools, Personal Protective Equipment, Road roller, Hand tools... |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

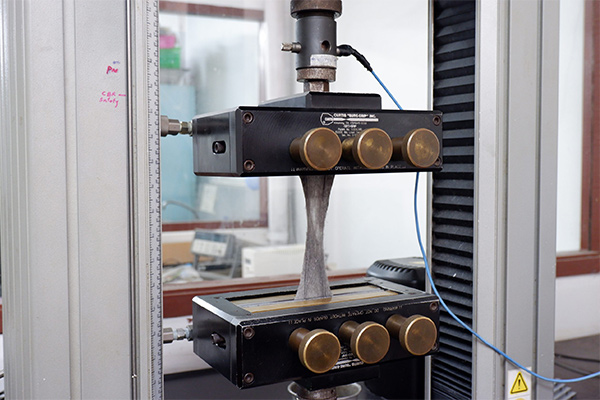

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Geocells were first developed in the early 1990s as a way to improve the stability of roads and bridges. They quickly gained popularity for their ability to stabilize soils and control erosion on steep grounds. Today, geocells are used in a variety of applications, including road construction, landfills, mining operations, and green infrastructure projects.

Geocells are used in construction to reduce erosion, stabilize soil, protect channels, and provide structural reinforcement for load support and earth retention.

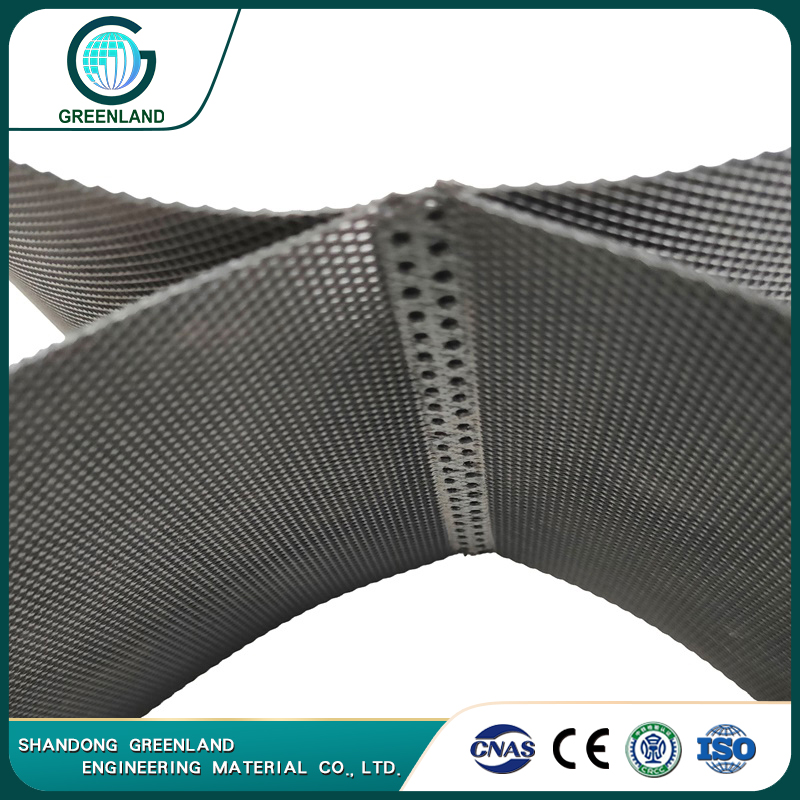

The Type Of HDPE/PP Geocells

The Type Of HDPE/PP Geocells

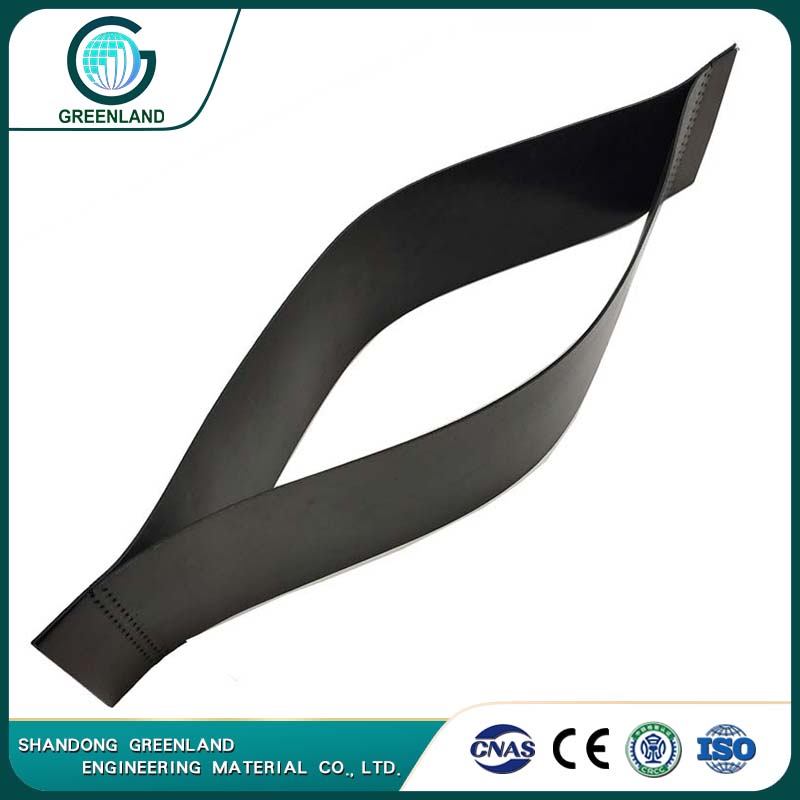

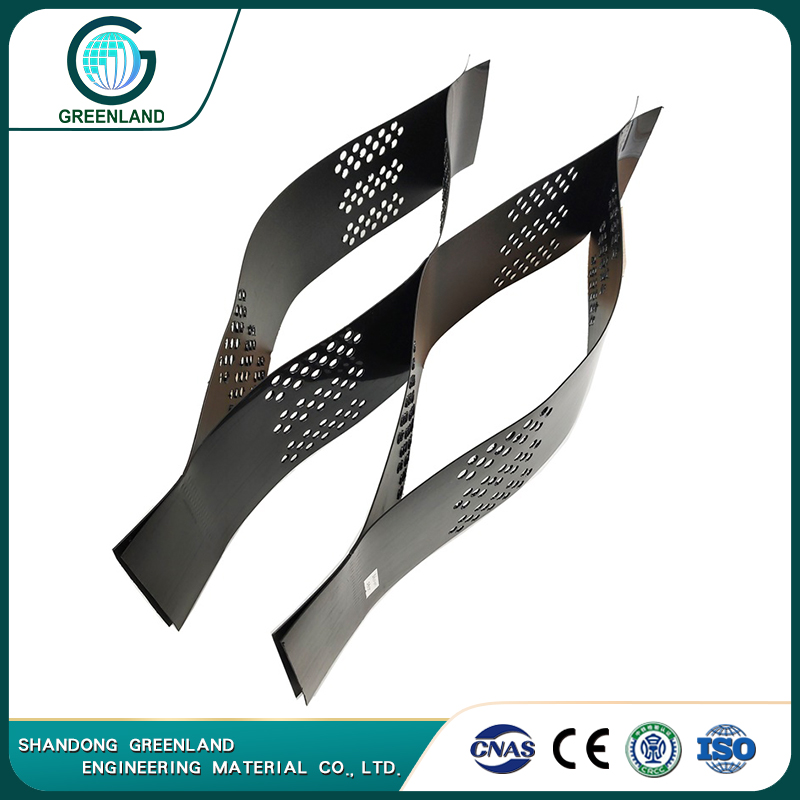

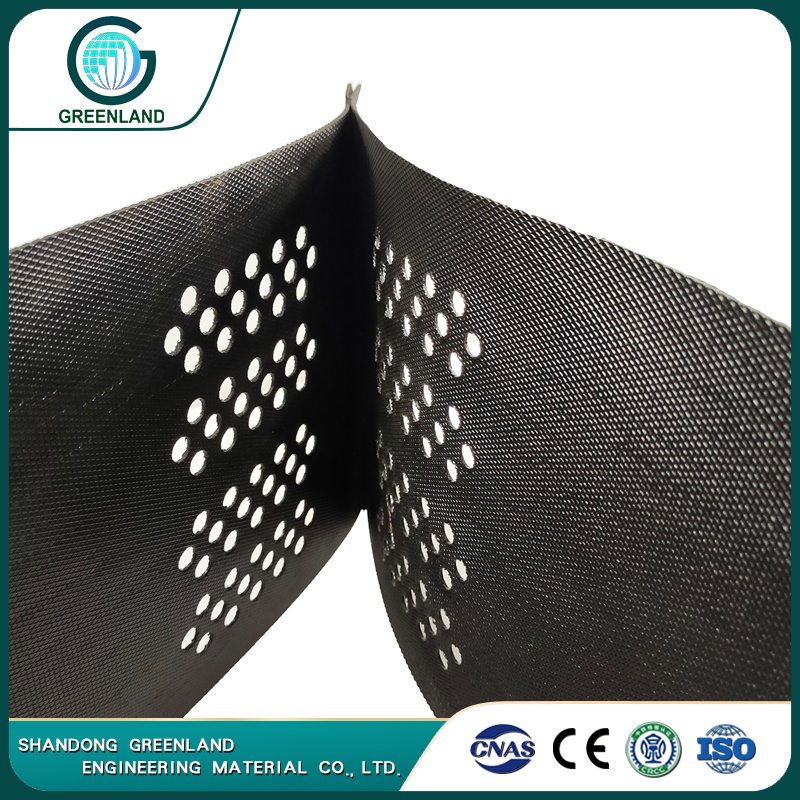

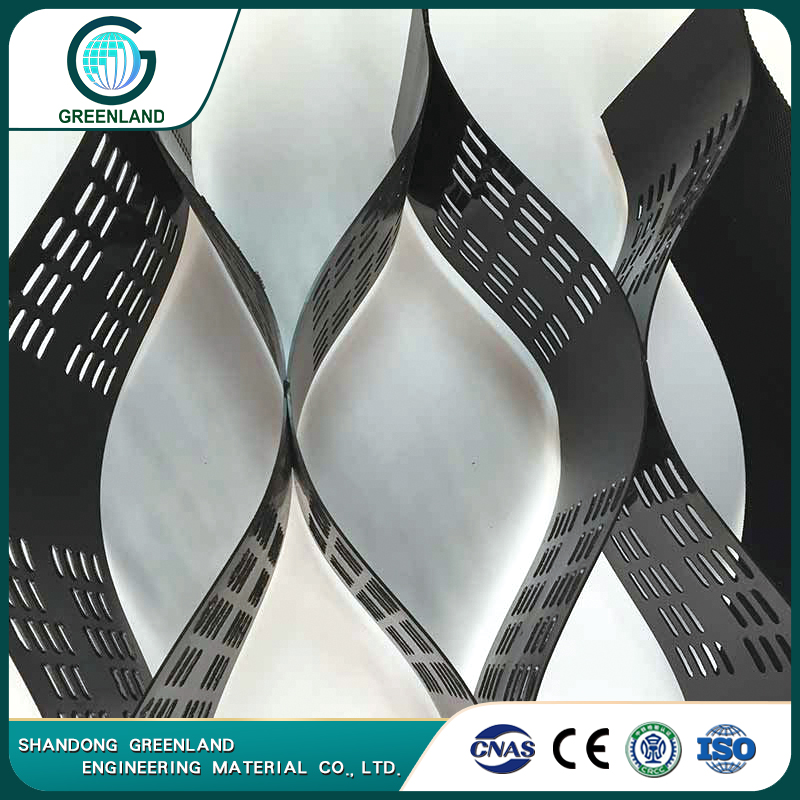

Geocells are available in various sorts and specifications to solve various issues with different soil types. The best way to categorize geocells is perforated and non-perforated geocells.

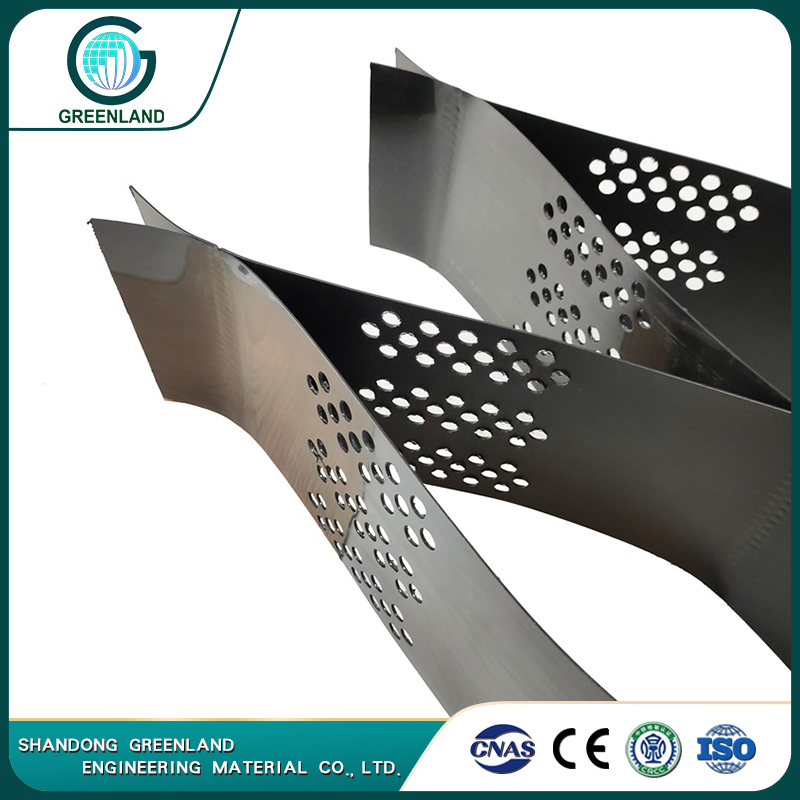

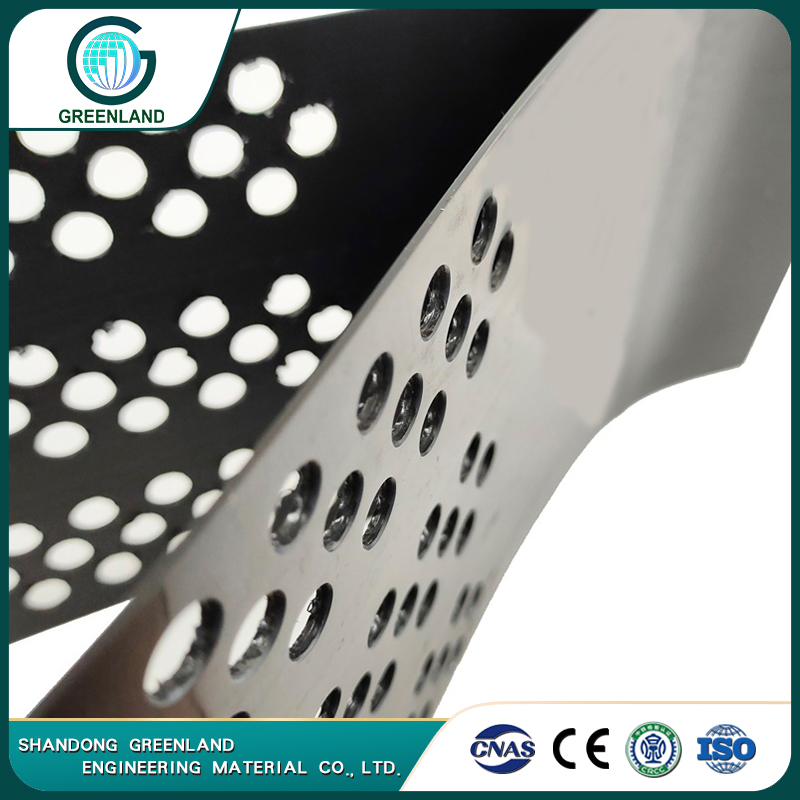

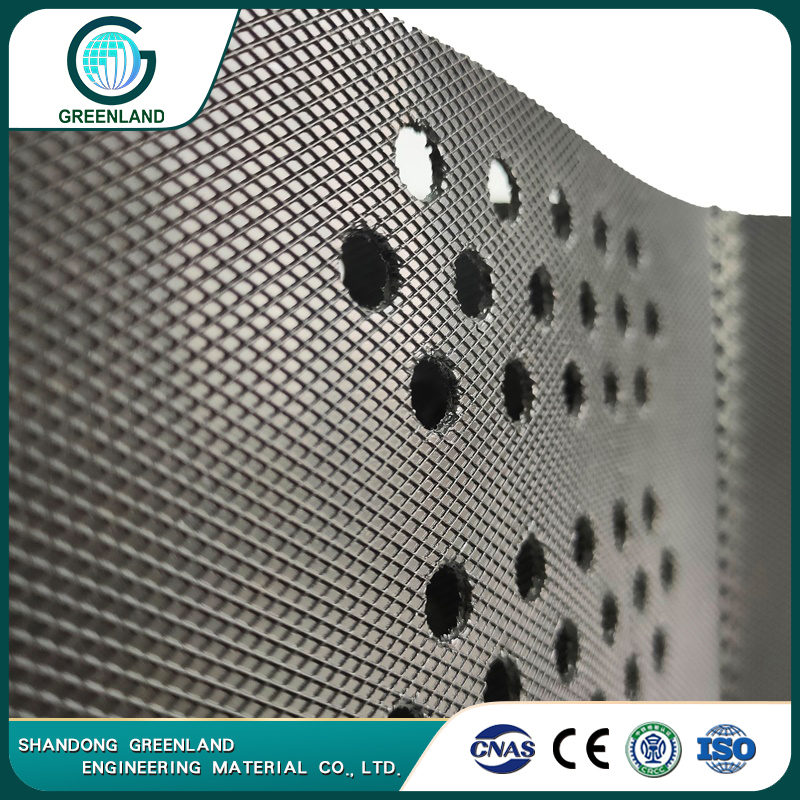

❖Perforated geocells have small holes in them that allow water and air to flow through. This type of geocell is best for applications where the soil needs to be able to breathe, like in a green infrastructure project.

What's more, the perforations improve load distribution and reduce distortion. They are made up of a series of strips that connect to form cells. The strength of the perforated strip and the weld determine the integrity of the geocell.

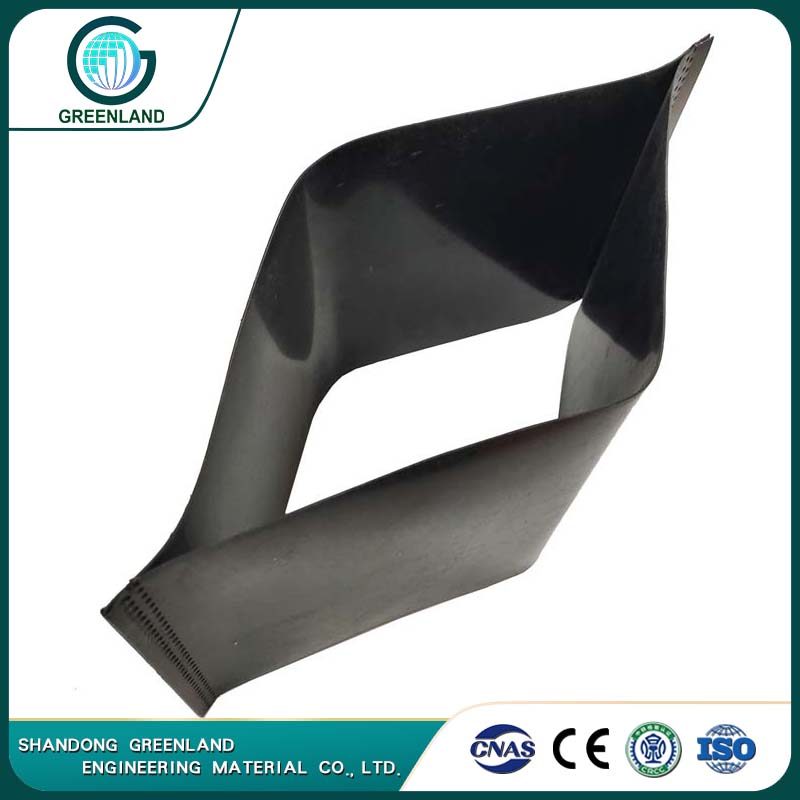

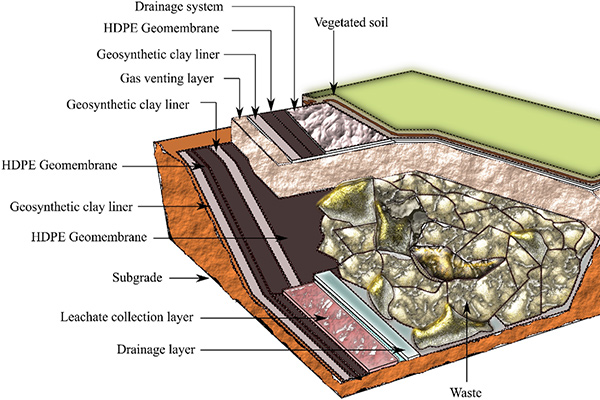

❖Non-perforated geocells have smooth, solid walls and are best for applications where water needs to be kept out, like in a landfill. The smooth walls prevent the infiltration of water and help keep the soil inside the cell.

Geomembranes and prefabricated vertical drains are occasionally used as application-specific alternatives to geocells.

Different Kinds and Applications of HDPE/PP Geocells

Different Kinds and Applications of HDPE/PP Geocells

|

|

|

| HDPE/PP Non-perforated Geocells | HDPE/PP Perforated Geocells | Customized HDPE/PP Geocells |

|

|

|

| HDPE/PP Geocells for Steep Slope Protection | HDPE/PP Geocells Geocells | PP Geocells |

Benefits of HDPE/PP Geocells

Benefits of HDPE/PP Geocells

Infrastructure development includes the design and construction of structures while ensuring that they do not have a detrimental influence on natural resources. Soil stabilization and reinforcement are a major source of worry and a possible threat to the long-term stability of roads, bridges, and pathways.

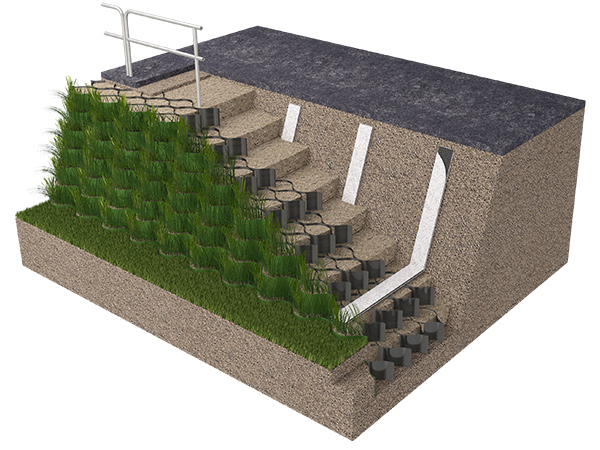

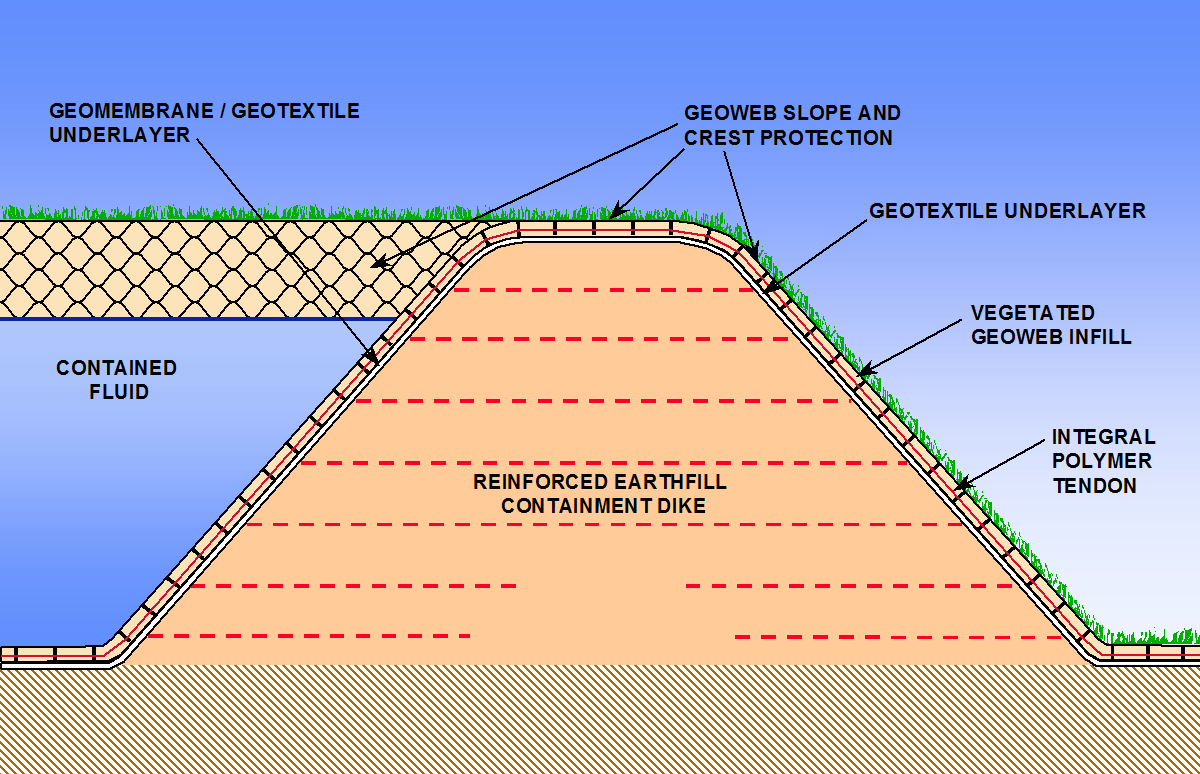

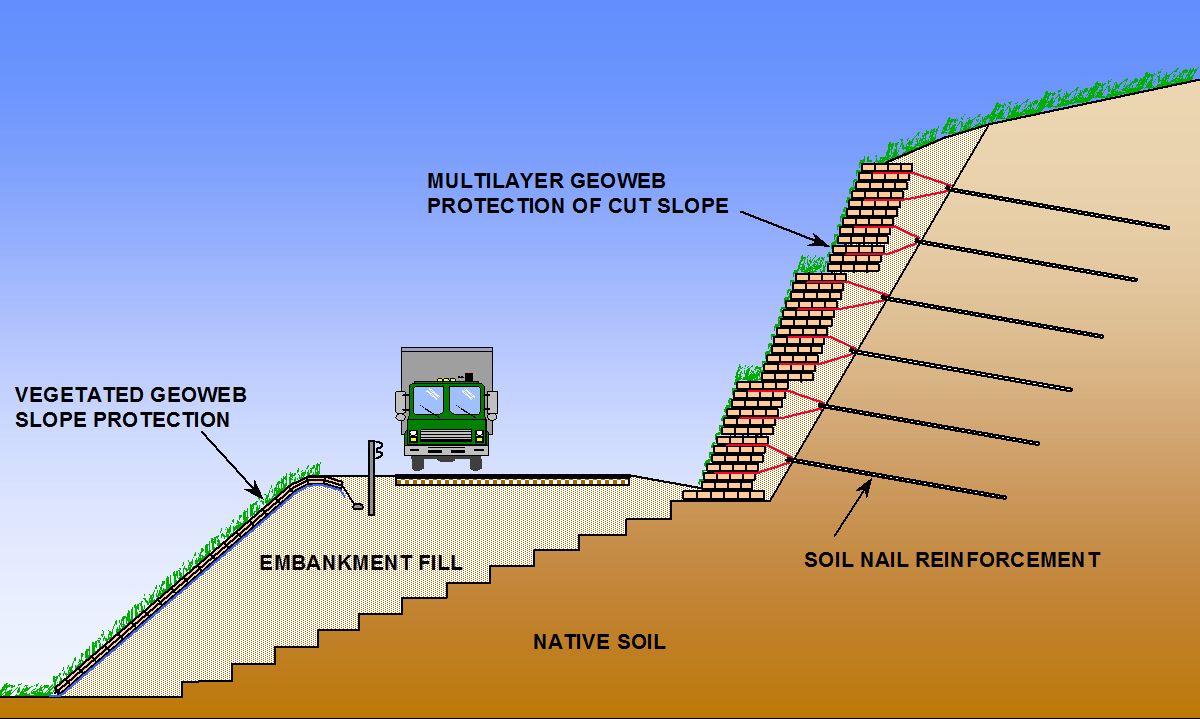

1. Protection and stabilization of steep slope surfaces/p>

2. Protective linings of channels and hydraulic structures

3. Static and dynamic load support on weak subgrade soils

4. Multi-layered earth-retaining and water-retaining gravity structures

5. Durable infrastructure

6. Enhanced slope protection

7. Environmentally friendly

Our Business Scope and What We Could Provide to You

Our Business Scope and What We Could Provide to You

|

|

|

| R&D and Design | Solutions Provider | Production and Delivery |

|

|

|

| Geosynthetics Testing | Industry Training | Construction Guidance |

Packing of Geogrids

Packing of Geogrids

|

|

|

Packaged by the Woven bag |

Width: 2-8m, Lenght: 50-100m/Roll |

☎Please Contact us to Get More Details and Geogrids Solutions, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

High-strength Integrally HDPE/PP Welded Geocell, also known as a cellular confinement system (CCS )which is suitable for use in supporting loads, such as those present on roads, railways, parking areas, and pavements. In particular, the geocells also retain their dimensions after large numbers of load cycles and temperature cycles; thus the required confinement of the infill is retained throughout the design life cycle of the geocell

| Specification of High-strength Integrally Welded Geocell | ||||||

| Material Properties | unit | Tested Method | ||||

| Cell Depth | mm | 75 | 100 | 150 | 200 | |

| Polymer Density | g/cm3 | 0.935-0.965 | ASTM D 1505 | |||

| Enviroment Stress Crack Resistance | Hours | >400 | ASTM D 5397 | |||

| Enviroment Stress Crack Resistance | Hours | 6000 | ASTM D 1693 | |||

| Carbon Black Content | % | 1.5%-2.0% | ASTM D 1603 | |||

| Nominal Sheet Thickness Before Texturing | mm | 1.27-5%,+10% | ASTM D 5199 | |||

| Nominal Sheet Thickness After Texturing | mm | 1.27-5%,+10% | ASTM D 5199 | |||

| Strip Puncture Resistance | N | 450 | ASTM D 4833 | |||

| Seam Peel Strength | N | 1065 | 1420 | 2130 | 2840 | EN ISO 13426-1B |

| Seam Efficiency | % | GRI100 | GRI-GS13 | |||

| Norminal Expanded Cell Size(width x length) | mm | 320x287,475x508 etc | ||||

| Norminal Expanded Panel Size(width x length | M | 2.56x8.35,4.5x5.0,6.5x4.5,6.1x2.44 | ||||

| Specification of High-strength Integrally Welded Geocell | ||||||

| Product Type | Height (mm) | Welding Distance (mm) | Thickness(mm) | Tensile Strength of Welding Points (N/cm) | Tensile Strength of Connection of Cells (N/cm ) | Tensile Strength at Yield of Each Sheet (MPa) |

| Smooth and Not Perforated | 50≤H≤300 | 300≤A≤1000 | 1.0 —1.5 | ≥100 | ≥120 | ≥20 |

| Smooth and Perforated | 50≤H≤300 | 300≤A≤1000 | 1.0 —1.5 | ≥100 | ≥120 | ≥20 |

| Textured and Not Perforated | 50≤H≤300 | 300≤A≤1000 | 1.3 —1.5 | ≥100 | ≥120 | ≥20 |

| Textured and Perforated | 50≤H≤300 | 300≤A≤1000 | 1.3 —1.5 | ≥100 | ≥120 | ≥20 |

| Remarks: | ||||||

| 1. This is a basic technical specification. | ||||||

| 2. All of the technical indexes can be reached according to the customers’demand, and the other special standards will be carried out by agreement or contact. | ||||||

| Geocell Mesh Size and Unfolded Area Calculation | |||||||

| Geogrid Model | Sheet material | Weld spacing(mm) | Sheet thickness(mm) | Peeling strength ≥(N) | Expanded panel size (mm) | Section expanded panel size | |

| Height(mm) | Smooth surface | Perforated | |||||

| TGLG-50-330 | 50 | 330 | 1.1 | 1.5 | 500 | 244X203 | 2.44X6.15 |

| TGLG-75-330 | 75 | 750 | 244X203 | 2.44X6.15 | |||

| TGLG-100-330 | 100 | 1000 | 244X203 | 2.44X6.15 | |||

| TGLG-150-330 | 150 | 1500 | 244X203 | 2.44X6.15 | |||

| TGLG-200-330 | 200 | 2000 | 244X203 | 2.44X6.15 | |||

| TGLG-100-356 | 100 | 356 | 1.1 | 1.5 | 1000 | 259X224 | 2.56X6.52 |

| TGLG-100-400 | 100 | 400 | 1.1 | 1.5 | 1000 | 295X250 | 4X5 5x6 |

| TGLG-100-445 | 100 | 445 | 1.1 | 1.5 | 1000 | 320X287 | 2.56X8.35 |

| TGLG-100-500 | 100 | 500 | 1.1 | 1.5 | 1000 | 370X310 | 3.7X6.2 |

| TGLG-100-660 | 100 | 660 | 1.1 | 1.5 | 1000 | 488X406 | 2.44X12.24 |

| TGLG-100-712 | 100 | 712 | 1.1 | 1.5 | 1000 | 508X475 | 2.56X13.72 |

| TGLG-100-800 | 100 | 800 | 1.1 | 1.5 | 1000 | 590X500 | 4X10 |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

☎Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Applications of HDPE/PP Geocells

Applications of HDPE/PP Geocells

Geocells have many engineering, economic and environmental benefits. They are a versatile, sustainable, and environmentally friendly solution for various applications. Geocells are the future of slope protection and should be used in any situation where stability and erosion control are necessary.

A geocell grid can solve numerous issues across various industries. Here are some of the industries that rely on geocells.

1. Landscape Architecture

2. Road Construction

3. Load Platform

4. Retaining Wall, Embankment, and Levees Reinforcement

5. Green Roofs and Walls

|

|

|

Geocells for Road Construction |

Geocell for Soil Reinforcement |

|

|

|

HDPE/PP Geocell for Slope Stabilization | Erosion Control |

HDPE/PP Geocells New Road Building |

☎Please Contact us to Get More Details About the Geocells, Send Email: sales@glgeosynthetics.com. or Mobile: (WhatsApp) +86 155 15596408.

HDPE/PP Geocells

- Below are the detailed information about HDPE/PP Geocells for your reference, Online preview and Download.

- Please contact us to get HDPE/PP Geocells Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now,

- Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- HDPE Geocell

DownLoad - High strength integrally welded geocell

DownLoad

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

☎Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.