Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

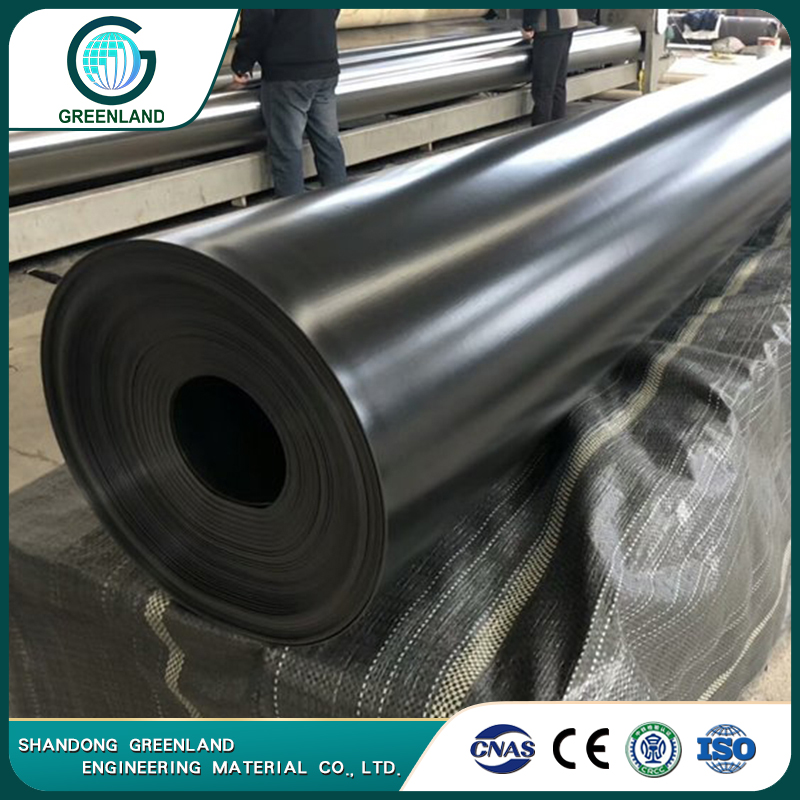

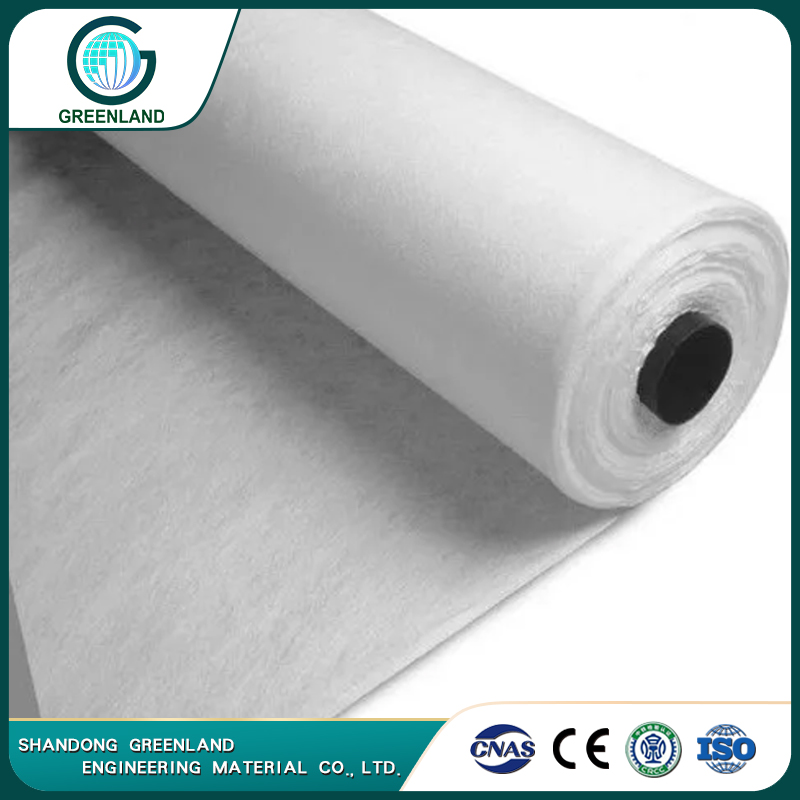

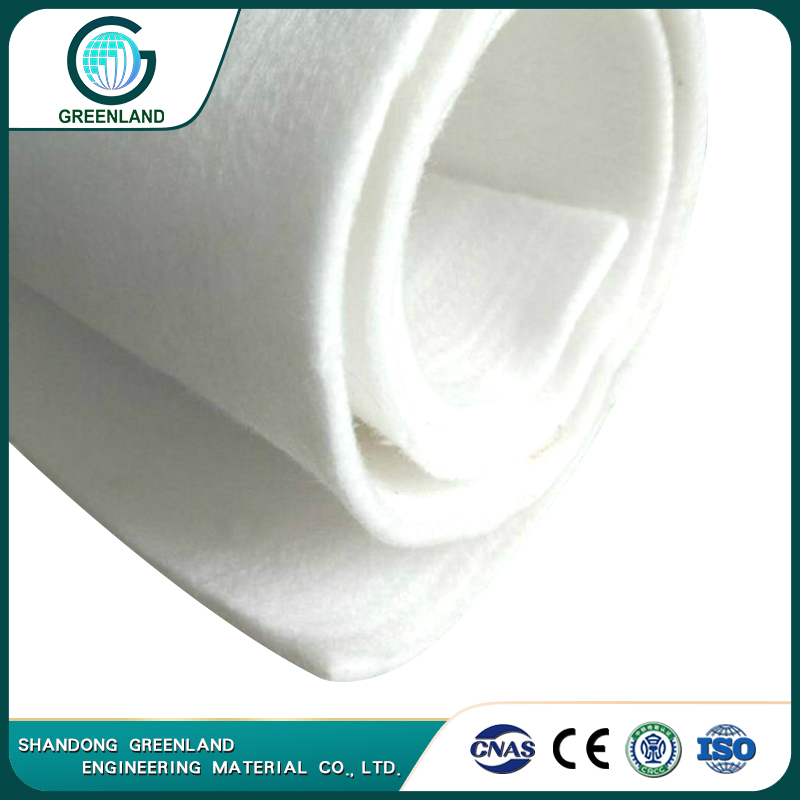

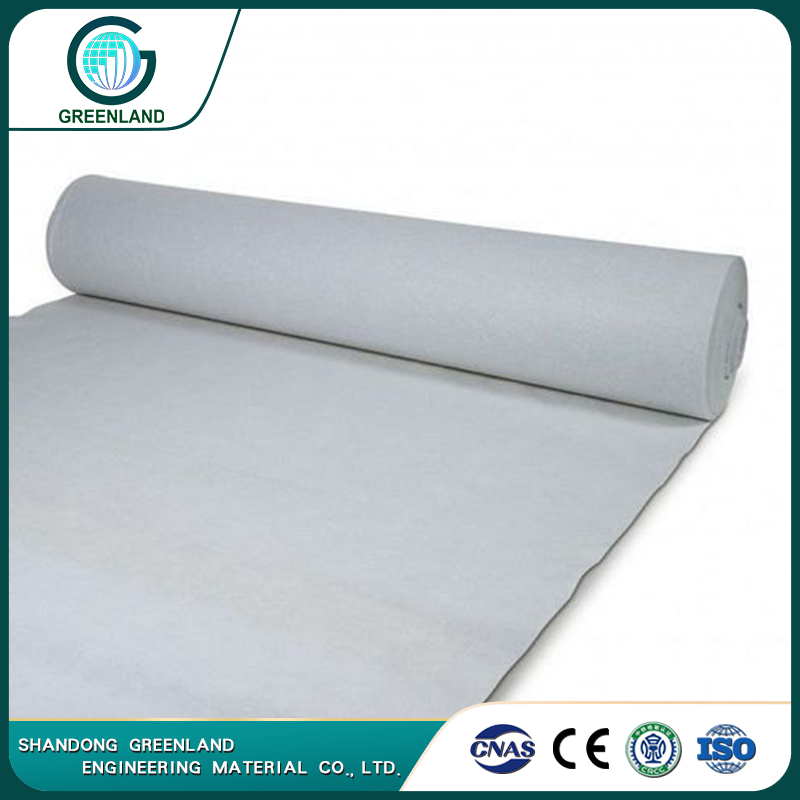

PET (Polyester) Short Fiber Nonwoven Geotextile

- 1.Tensile strength: 3.0-40.0kN/m

- 2.Width: Max. 8M

- 3.Raw material: PP. PET

- 4.Standards: GRI-GT12/GT13, ASTM, ISO, GB/T 17638-2017

- 5.Delivery period: stock, 5-10 days production date

- 6.Packing: 50-100m length/roll

- 7.MOQ: Trial order is acceptable

- 8.Free Sample

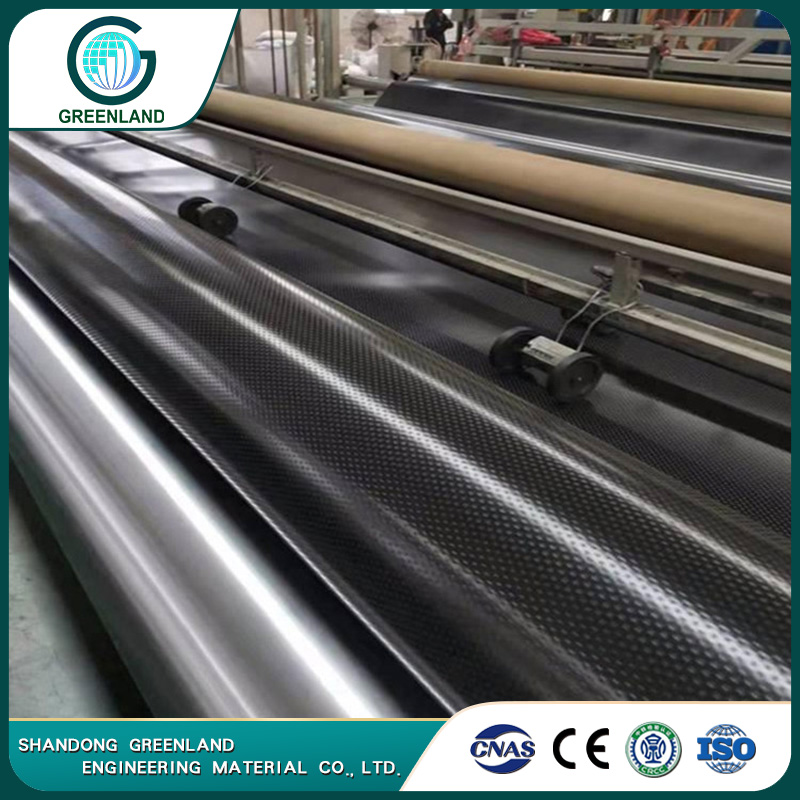

Polyester short fiber nonwoven geotextile is a kind of infiltrated geotechnical synthetic material formed by different equipment and processes with different equipment and processes.

Polyester short fiber nonwoven geotextile generally has a width of 4-6 meters and a length of 50-100 meters. Polyester short fiber nonwoven geotextile has a certain degree of tear resistance and deformation adaptability due to its soft fibers, as well as good flat drainage ability, which can play a good role in filtering, isolation, reinforcement, protection, and other functions. Polyester short fiber non-woven geotextile is suitable for soil filtration, soil separation, soil reinforcement and other engineering projects.

Quick Details of PET (Polyester) Short Fiber Nonwoven Geotextile

Quick Details of PET (Polyester) Short Fiber Nonwoven Geotextile

| Products details information | |

| Product name | PET (Polyester) Short Fiber Nonwoven Geotextile |

| Brand | Greenland (OEM is available) |

| Tensile strength | 3.0-40.0kN/m |

| Raw material | PP, PET |

| Application | Railway lines, roads, sports venues, river embankments, soil and water engineering construction, tunnels, mudflat in coastal areas, reclamation, environmental protection and other engineering projects. |

| Color | Black, White, Green, other colors |

| Standards | GRI-GT12/GT13, ASTM, ISO, GB/T 17638-2017 |

| Company/Factory Strength | |

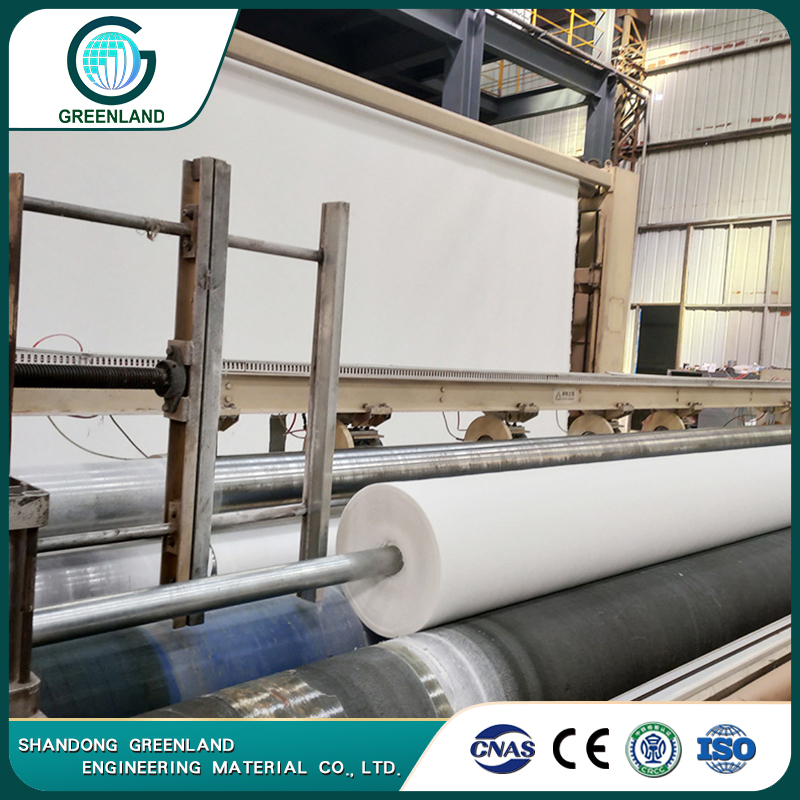

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of PET (Polyester) Short Fiber Nonwoven Geotextile

Description of PET (Polyester) Short Fiber Nonwoven Geotextile

PET short fiber nonwoven geotextile is a geosynthetic material made from polyester fibers through thermal bonding or needle punching processes. Polyester short fiber nonwoven geotextile has high flexibility and impermeability, and can adapt to different shapes and curves of geotextiles, with good adaptability. Polyester staple nonwoven geotextile can effectively prevent the loss of soil particles, block the penetration of fluid, and improve the anti scouring ability of soil. It is widely used in railway lines, roads, sports venues, river embankments, soil and water engineering construction, tunnels, mudflat in coastal areas, reclamation, environmental protection and other engineering projects.

|

|

|

| Good filtering performance | Good permeability | Good stretchability |

|

|

|

| High toughness | High strength | High corrosion resistance |

Benefits of PET (Polyester) Short Fiber Nonwoven Geotextile

Benefits of PET (Polyester) Short Fiber Nonwoven Geotextile

Polyester short fiber nonwoven geotextile has advantages such as high strength, strong puncture resistance, microbial resistance, aging resistance, high temperature resistance, superior permeability, filtration, and soil retention.

- 1. By utilizing the good breathability and water permeability of geotextiles, water can flow through and effectively retain sand and soil loss.

- 2. Geotextiles have good water conductivity and can form drainage channels inside the soil to discharge excess liquids and gases from the soil structure.

- 3. Utilizing geotextiles to enhance the tensile strength and deformation resistance of soil, enhance the stability of building structures, and improve soil quality.

- 4. Effectively diffusing, transmitting, or decomposing concentrated stress to prevent soil from being damaged by external forces.

- 5. Prevent mixing between upper and lower layers of sand, soil, and concrete.

- 6. Due to the variability and mobility of the network structure formed by amorphous fibrous tissue, the mesh is not easily blocked.

- 7. Under the pressure of soil and water, it can still maintain good permeability.

- 8. Made from polypropylene fiber, it is acid and alkali resistant, non corrosive, insect resistant, and antioxidant.

- 9. Lightweight, easy to use, and easy to construct.

Please Contact us to Get More Details, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

Specifications of PET (Polyester) Short Fiber Nonwoven Geotextile

Specifications of PET (Polyester) Short Fiber Nonwoven Geotextile

1. New Standard for Geotextile (GB/T 17638-2017)

| 1 | Item | Nominal fracture strength/(kN/m) | ||||||||

| 2 | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | |

| 3 | Longitudinal and transverse fracture strength /(KN/m)≥ | 3.0 | 5.0 | 8.0 | 10.0 | 15.0 | 20.0 | 25.0 | 30.0 | 40.0 |

| 4 | Elongation corresponding to nominal fracture strength /% | 20-100 | ||||||||

| 5 | Bursting Strength /kN≥ | 0.6 | 1.0 | 1.4 | 1.8 | 2.5 | 3.2 | 4.0 | 5.5 | 7.0 |

| 6 | Deviation rate of mass per unit area /% | ±5 | ||||||||

| 7 | Width deviation rate % | -0.5 | ||||||||

| 8 | Thickness deviation rate % | ±10 | ||||||||

| 9 | equivalent aperture O90(O95) /mm | 0.07-0.20 | ||||||||

| 10 | Vertical permeability coefficient cm/s | Kx(10-1-10-3 ) among K=1.0-9.9 | ||||||||

| 11 | Vertical and horizontal tearing strength /kN≥ | 0.10 | 0.15 | 0.20 | 0.25 | 0.40 | 0.50 | 0.65 | 0.80 | 1.00 |

| 12 | Acid and alkali resistance (strong retention rate) %≥ | 80 | ||||||||

| 13 | Antioxidant performance (strong retention rate) %≥ | 80 | ||||||||

| 14 | UV resistance performance (strong retention rate) %≥ | 80 | ||||||||

2. ASTM Standard for PET (Polyester) Short Fiber Nonwoven Geotextile

| Index Properties |

Test Method |

Unit | Values | |||||||||||

| Weight | ASTM D5261 |

g/m2 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Ultimate Tensile Strength |

ASTM D4595 |

≥kN/m | 2.5 | 3.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 17.5 | 19.0 |

| Tensile Elongation |

ASTM D4595 |

% | 50 | |||||||||||

| Grab Tensile Strength |

ASTM D4632 |

≥N | 225 | 280 | 361 | 641 | 720 | 792 | 911 | 1036 | 1182 | 1346 | 1480 | 1584 |

| Grab Elongation | ASTM D4632 |

% | 50 | |||||||||||

| Trapezoid Tear Strength |

ASTM D4533 |

≥N | 80 | 100 | 120 | 160 | 200 | 240 | 280 | 330 | 380 | 420 | 440 | 460 |

| CBR Puncture Strength |

ASTM D6241 |

≥N | 0.3 | 0.4 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 2.9 | 3.2 |

| Puncture Resistance |

ASTM D4833 |

≥N | 82 | 99 | 133 | 225 | 284 | 346 | 440 | 530 | 596 | 603 | 663 | 760 |

| Drop Cone Resistance(hole-φ) |

BS EN 918 |

mm | 45 | 40 | 37 | 34 | 31 | 26 | 23 | 19 | 18 | 16 | 15 | 15 |

| Hydraulic Properties | ||||||||||||||

| Apparent Opening Size 090 |

ASTM D4751 |

≤mm | 0.13 | 0.12 | 0.12 | 0.12 | 0.12 | 0.11 | 0.10 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 |

| Permeability | ASTM D4491 |

cm/s | 0.41 | 0.41 | 0.41 | 0.41 | 0.40 | 0.40 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 |

| Physical Identification Properties | ||||||||||||||

| Thickness | ASTM D5199 |

mm | 1.0 | 1.3 | 1.7 | 2.1 | 2.4 | 2.5 | 2.8 | 3.0 | 3.2 | 3.5 | 3.6 | 3.8 |

| Roll Width | - | m | 4-6 | |||||||||||

| Approx Load Qty per 40HQ | M2 | 72000 | 57600 | 48000 | 36000 | 28800 | 24000 | 20400 | 18000 | 15600 | 14000 | 13200 | 12000 | |

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

- 1. Thermal insulation and moisture protection of basic pavement;

- 2. Isolation filtration and seepage materials for soil layer separation in drainage work;

- 3. Anti erosion materials for embankments, river channels, and slope protection buildings, as well as reinforcement materials for railway, highway, and airport roadbeds;

- 4. Reinforcement materials for road construction in swampy areas;

- 5. Anti cracking materials for asphalt pavement;

- 6. Plant frost and frost resistant insulation materials in landscaping. The effect is better when used in combination with geotextile.

❖PET (Polyester) Short Fiber Nonwoven Geotextile for Railway & Highway

1.Roadbed Reinforcement

2.Pavement Maintenance

3.Railway Bed Reinforcement

|

|

| PET Short Fiber Nonwoven Geotextile for Artificial Fill Foundation Drainage | PET Short Fiber Nonwoven Geotextile for Highway Pavement Maintenance |

|

|

| PET Short Fiber Nonwoven Geotextile for Railway | PET Short Fiber Nonwoven Geotextile for Road Reinforcement |

Please Contact us to Get More Projects Cases, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

PET (Polyester) Short Fiber Nonwoven Geotextile

- Below are the detailed information on PET short fiber nonwoven geotextile for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- PET Short Fiber Nonwoven Geotextile

DownLoad

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.