Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

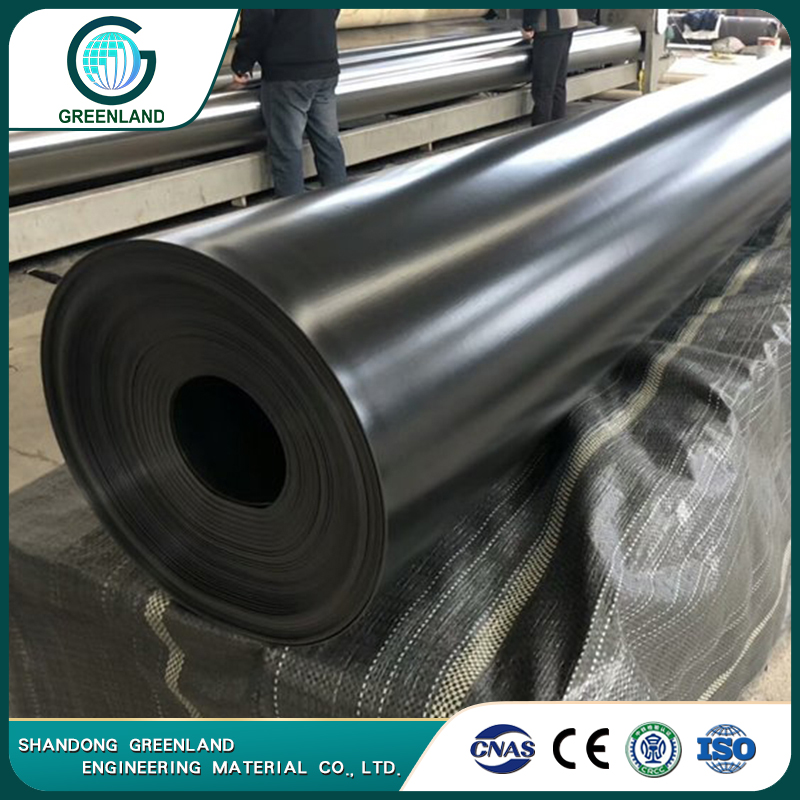

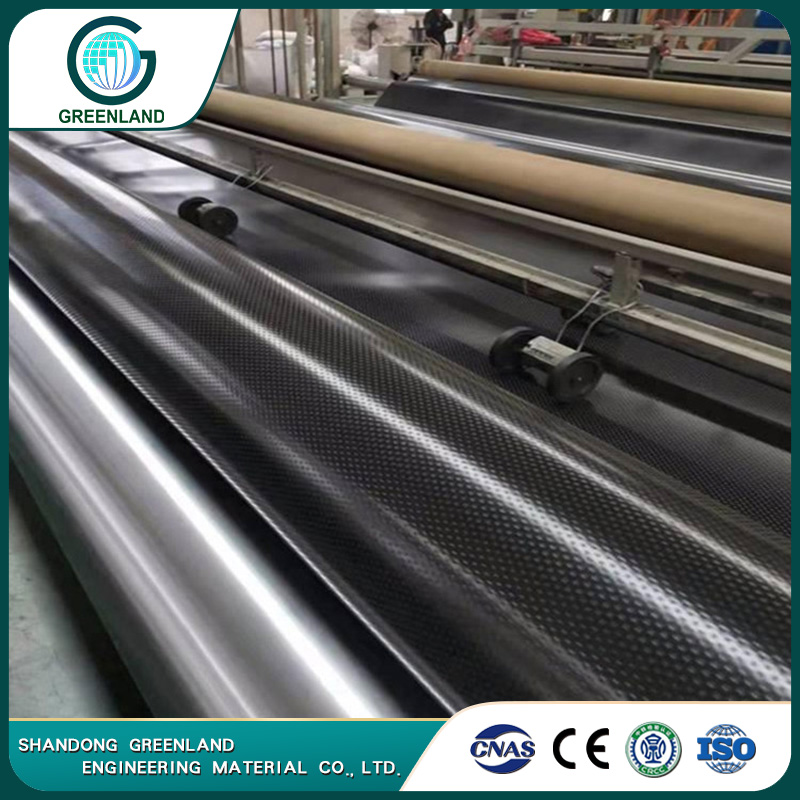

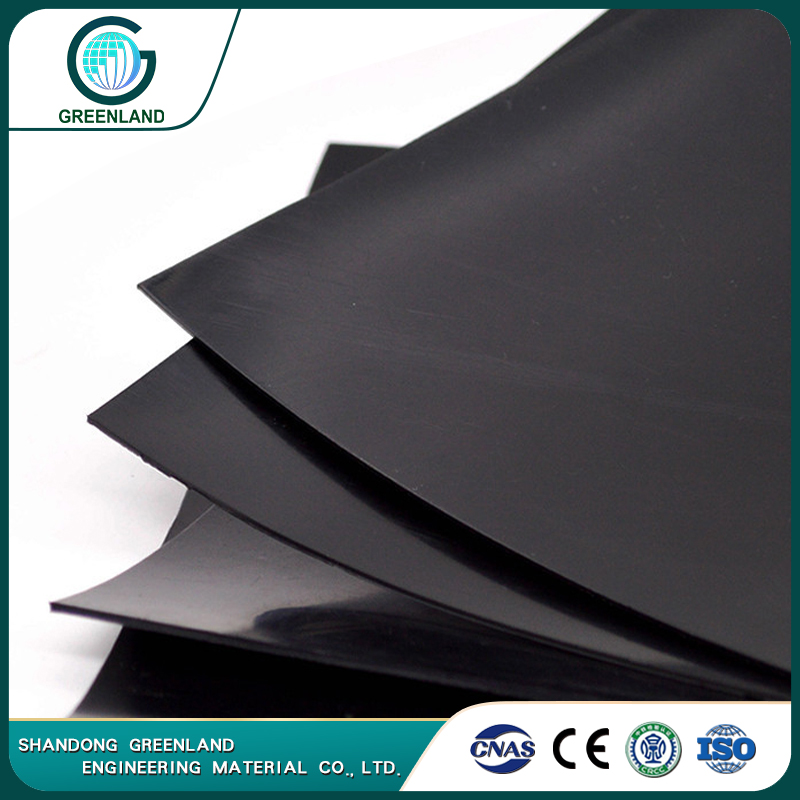

HDPE Smooth Surface Geomembrane

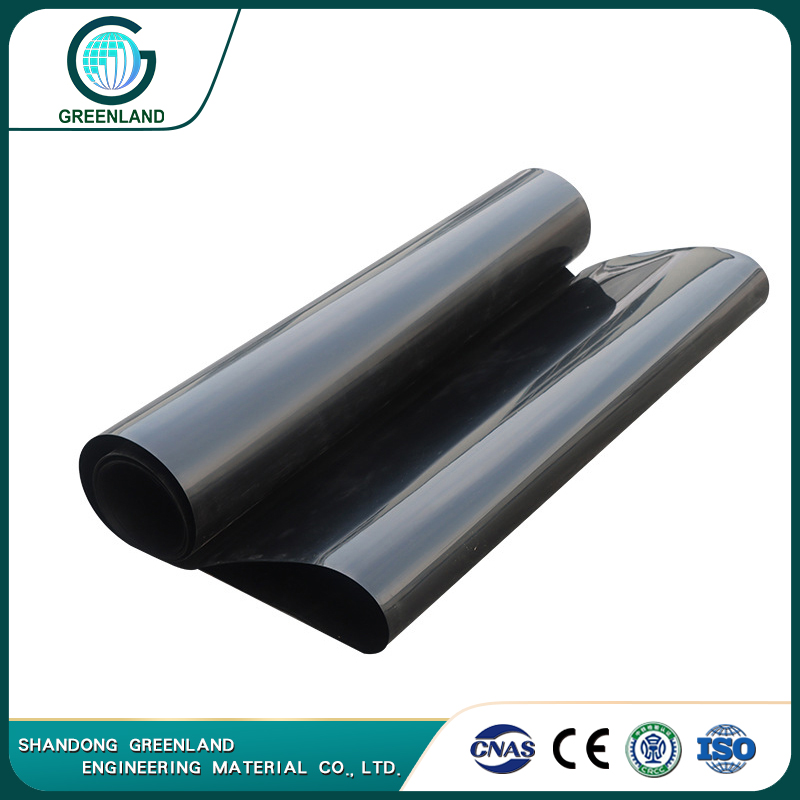

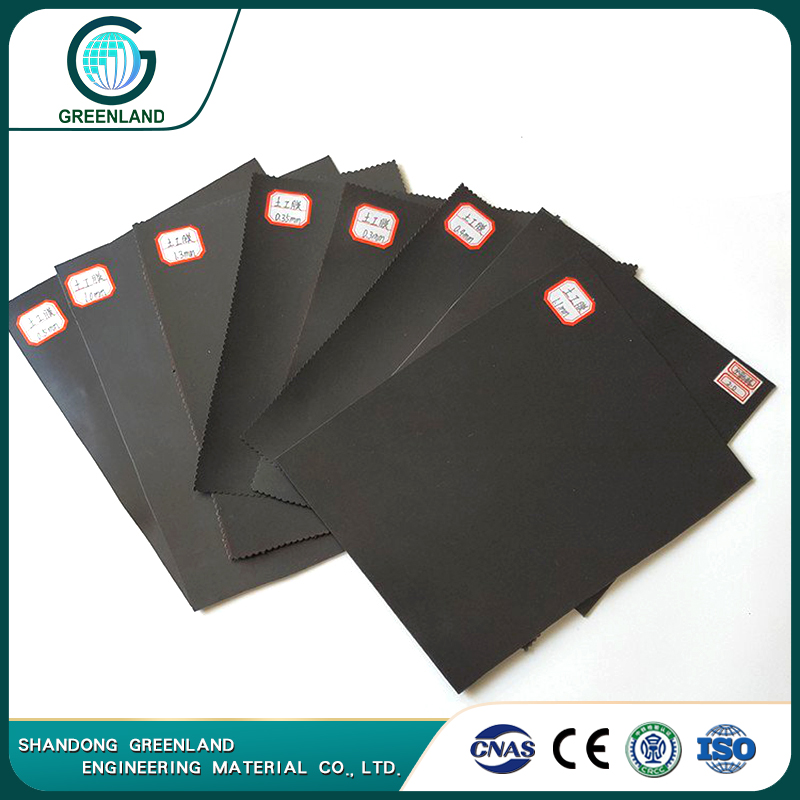

- 1.Thickness: 0.2-4.0mm (0.008inch-0.157inch)

- 2.Width: Max. 8M

- 3.Raw material: PE100, PE80, HDPE, LDPE, LLDPE, ECB, PVC, EVA…

- 4.Standards: ASTM GM13, ISO, GH-1 GB/T17643-2011

- 5.Delivery period: stock, 5-10 days production date

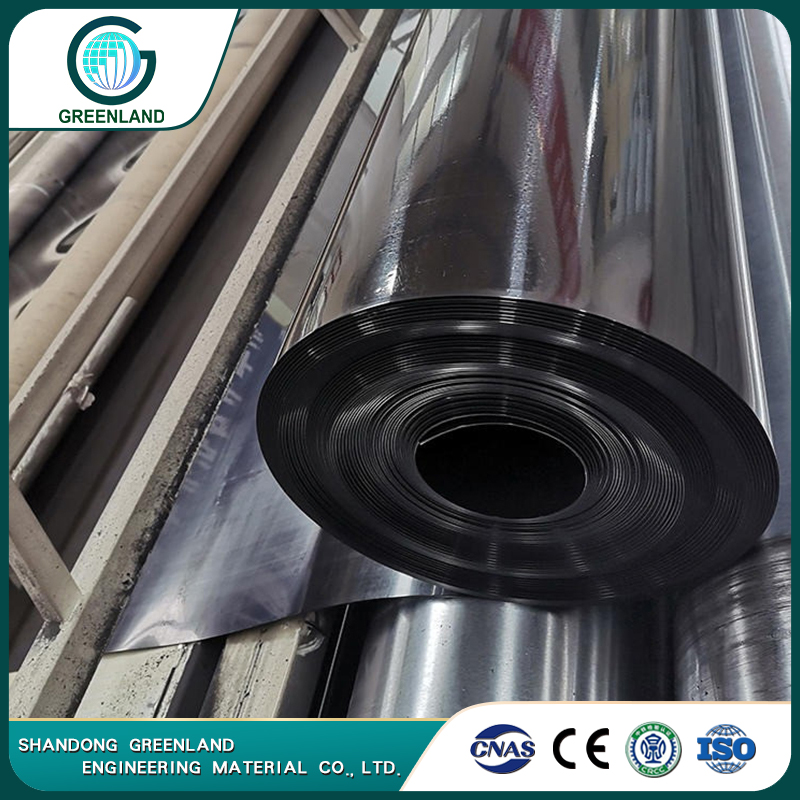

- 6.Packing: 50-100m length/roll

- 7.MOQ: Trial order is acceptable

- 8.Free Sample

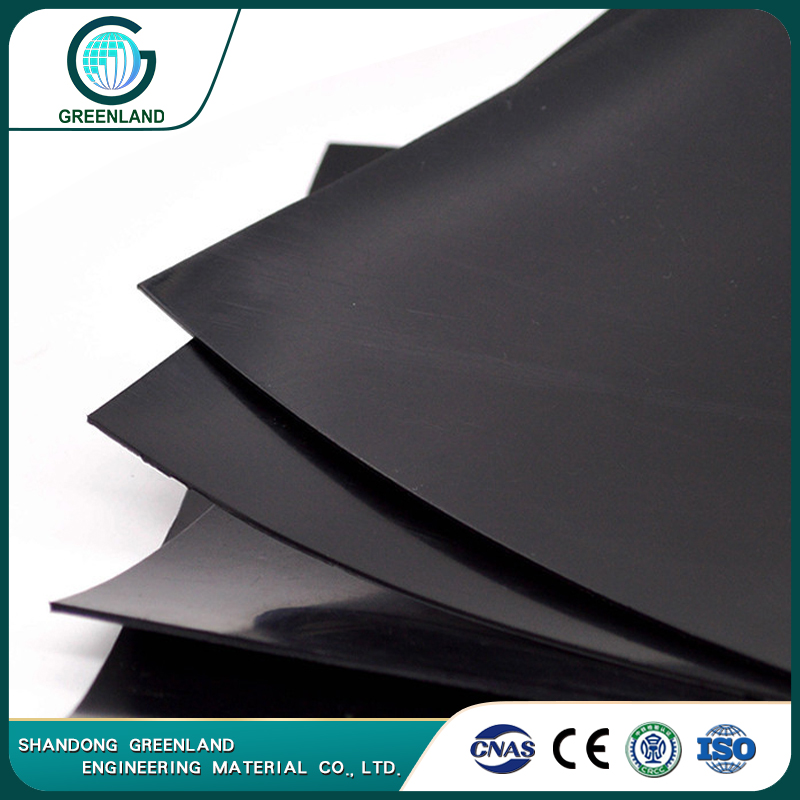

HDPE smooth surface geomembrane is a kind of waterproof barrier material with smooth surface produced with high-density polyethylene resin as raw material, which has excellent resistance to environmental stress cracking, low temperature, aging and corrosion resistance. Widely used in anti-seepage projects such as domestic waste landfill, solid waste landfill, sewage treatment plant, artificial lake, and tailings pond treatment.

Quick Details of HDPE (High Density Polyethylene) Smooth Geomembrane

Quick Details of HDPE (High Density Polyethylene) Smooth Geomembrane

| Products details information | |

| Product name | HDPE (High Density Polyethylene) Smooth Surface Geomembrane |

| Brand | Greenland (OEM is available) |

| Thickness | 0.2-4.0mm (0.008inch-0.157inch) |

| Raw material | HDPE, LDPE, LLDPE, EVA, PVC, ECB... |

| Application | Landfill bottoms, artificial lakes, rivers, reservoirs, golf course pond bottoms, drinking water tanks, agricultural irrigation systems, factory aquaculture ponds, fish ponds, shrimp ponds, waterproofing engineering, tunnel lining, anti-seepage of canals and reservoirs, etc. |

| Color | Black, White, other colors |

| Standards | ASTM GM13, ISO, GH-1 GB/T17643-2011 |

| Welding Tools | Hot wind welding, roller welding machine, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of HDPE (High Density Polyethylene) Smooth Surface Geomembrane

Description of HDPE (High Density Polyethylene) Smooth Surface Geomembrane

HDPE smooth surface geomembrane is a waterproof material made by using high-density polyethylene native resin, additives, antioxidants, UV absorbers, stabilizers and other auxiliary materials, and through three-layer co extrusion technology. It has high tensile strength, strong corrosion resistance, and good anti-seepage effect. Specifications above 1.0mm are suitable for landfill sites, tailings storage sites, channel anti-seepage, and dam anti-seepage engineering.

|

|

|

| Flexible waterproof material | Environmental stress cracking resistance | Chemical corrosion performance |

|

|

|

| Anti-aging performance | Excellent tensile strength | Strong weather resistance |

Benefits of HDPE (High Density Polyethylene) Smooth Surface Geomembrane

Benefits of HDPE (High Density Polyethylene) Smooth Surface Geomembrane

HDPE smooth surface geomembrane has good heat and cold resistance. The anti-seepage membrane of biogas digesters has good chemical stability, high rigidity and toughness, good mechanical strength, good resistance to environmental stress cracking and tear strength. As the density increases, the mechanical and barrier properties will correspondingly improve, and the heat resistance and tensile strength will also be higher; It can withstand corrosion from acids, alkalis, organic solvents, etc.

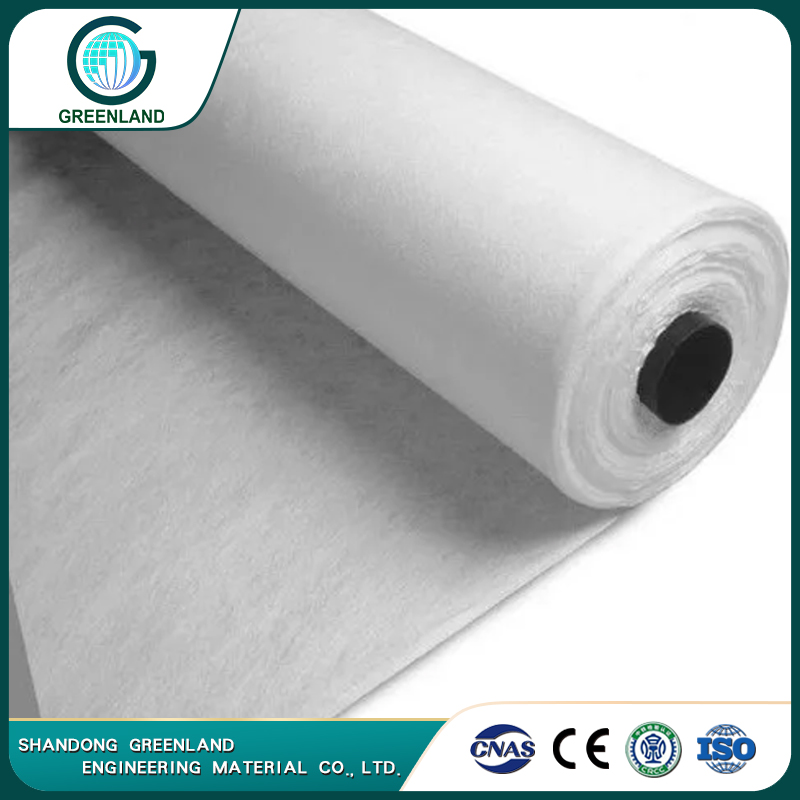

- 1. It does not contain chemical additives or undergo heat treatment, making it an environmentally friendly building material.

- 2. It has good mechanical properties, good water permeability, corrosion resistance and aging resistance.

- 3. It has strong resistance to burial and corrosion, with a fluffy structure and excellent drainage performance.

- 4. It has good friction coefficient and tensile strength, and has geotechnical reinforcement performance.

- 5. It has functions such as isolation, filtration, drainage, protection, stability, and reinforcement.

- 6. It can adapt to uneven base layers, resist external construction damage, and have low creep.

- 7. Good overall continuity, light weight, and convenient construction.

- 8. As a permeable material, it has excellent anti filtration and isolation function, strong puncture resistance, and therefore has good protective performance.

Please Contact us to Get More Details, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

Specifications of HDPE (High Density Polyethylene) Smooth Surface Geomembrane

Specifications of HDPE (High Density Polyethylene) Smooth Surface Geomembrane

1. Performance Parameter Table for Ordinary HDPE Smooth Surface Geomembrane (GB/T17643-2011 standard)

| Number | Item | Indicators | ||||||||

| Thickness (mm) | 0.3 | 0.5 | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |

| 1 | Density (g/m³) | ≥0.940 | ||||||||

| 2 | Longitudinal and transverse tensile yield strength (N/mm) | ≥4 | ≥7 | ≥10 | ≥13 | ≥16 | ≥20 | ≥26 | ≥33 | ≥40 |

| 3 | Longitudinal and transverse tensile fracture strength (N/mm) | ≥6 | ≥10 | ≥15 | ≥20 | ≥25 | ≥30 | ≥40 | ≥50 | ≥60 |

| 4 | Longitudinal and transverse yield elongation (%) | - | - | ≥11 | ||||||

| 5 | Longitudinal and transverse elongation at break (%) | ≥600 | ||||||||

| 6 | Vertical and horizontal right angle tear load (N) | ≥34 | ≥56 | ≥84 | ≥115 | ≥140 | ≥170 | ≥225 | ≥280 | ≥340 |

| 7 | Puncture resistance strength (N) | ≥72 | ≥120 | ≥180 | ≥240 | ≥300 | ≥360 | ≥480 | ≥600 | ≥720 |

| 8 | Carbon black content (%) | 2.0~3.0 | ||||||||

| 9 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||||

| 10 | Induction time of atmospheric pressure oxidation(OIT)(min) | ≥60 | ||||||||

| 11 | Low temperature impact embrittlement performance | Pass | ||||||||

| 12 | Water vapor permeability coefficient g·cm/(cm·s·Pa) | ≤1.0×10-13 | ||||||||

| 13 | Dimensional stability (%) | ±2.0 | ||||||||

| Note: The technical performance indicators for thickness specifications not listed in the table are required to be executed using interpolation method. | ||||||||||

2. Performance Parameter Table for Environmentally Friendly HDPE Smooth Surface Geomembrane (GB/T17643-2011 GH-2S standard)

| Number | Item | Indicators | ||||||

| 1 | Thickness (mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 |

| 2 | Density (g/cm³) | ≥0.940 | ||||||

| 3 | Tensile yield strength (woven, transverse)N /mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (woven, transverse) N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse) % | ≥700 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

| 8 | Puncture resistance strength (N) | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 |

| 9 | Tensile load stress cracking (notch constant load tensile method) h | ≥300 | ||||||

| 10 | Carbon black content (%) | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | Atmospheric pressure oxidation induction time (OIT) (min) | Induction time of atmospheric pressure oxidation ≥100 | ||||||

| Induction time of high-pressure oxidation ≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

3. HDPE Smooth Surface Geomembrane for Landfill Sites-Technical Specifications CJ/T 234-2006 (equivalent to US GRI-GM13 standard)

| Number | Item | Indicators | ||||||

| 1 | Thickness (mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 |

| 2 | Density (g/cm³) | ≥0.939 | ||||||

| 3 | Tensile yield strength (woven, transverse) N /mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (woven, transverse) N/mm | ≥20 | ≥27 | ≥33 | ≥40 | ≥53 | ≥67 | ≥80 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse) % | ≥700 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥156 | ≥187 | ≥249 | ≥311 | ≥374 |

| 8 | Puncture resistance strength (N) | ≥240 | ≥320 | ≥400 | ≥480 | ≥640 | ≥800 | ≥960 |

| 9 | Resistance to environmental stress cracking | ≥300 | ||||||

| 10 | Carbon black content (%) | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | Atmospheric pressure oxidation induction time (OIT) (min) | Induction time of atmospheric pressure oxidation ≥100 | ||||||

| Induction time of high-pressure oxidation ≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

4. Technical Indicators of HDPE Smooth Surface Geomembrane for Anti-seepage In Aquaculture

| Number | Item | Indicators | ||||||||

| 1 | Thickness (mm) | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

| 2 | Density (g/cm³) | ≥ 0.939 | ||||||||

| 3 | Tensile yield strength (woven, transverse) N /mm | ≥6 | 2 9 | ≥14 | ≥ 19 | ≥ 23 | ≥28 | ≥37 | ≥47 | ≥ 56 |

| 4 | Tensile fracture strength (woven, transverse) N/mm | ≥ 560 | ||||||||

| 5 | Right angle tear load (longitudinal and transverse) N | ≥ 27 | ≥45 | ≥ 63 | ≥ 90 | ≥108 | ≥135 | ≥180 | ≥ 225 | ≥ 270 |

| 6 | Puncture resistance strength (N) | ≥ 52 | ≥84 | ≥135 | ≥175 | ≥220 | ≥ 260 | ≥ 350 | > 435 | > 525 |

| 7 | Carbon black content (%) | 2.0-3.0 | ||||||||

| 8 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed | ||||||||

| 9 | Atmospheric pressure oxidation induction time (OIT) (min) | ≥ 60 | ||||||||

| 10 | Low temperature impact embrittlement performance | Pass | ||||||||

| 11 | Water vapor permeability coefficient g·cm/(cm·s·Pa) | 1.0×10-13 | ||||||||

| 12 | Dimensional stability % | ±2.0 | ||||||||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Due to the low friction characteristics of HDPE smooth surface geomembrane, it is often used in situations where liquid resistance needs to be reduced, such as landfill bottoms, artificial lakes, rivers, reservoirs, golf course pond bottoms, drinking water tanks, agricultural irrigation systems, factory aquaculture ponds, fish ponds, shrimp ponds, waterproofing engineering, tunnel lining, anti-seepage of canals and reservoirs, etc. Its surface is smooth and more convenient to use.

❖HDPE (High Density Polyethylene) Smooth Surface Geomembrane for Agricultural Irrigation & Waterproof Engineering

1.Aquaculture anti-seepage

2.Agricultural irrigation system

3.River anti-seepage

|

|

| HDPE Smooth Surface Geomembrane for Water Storage | HDPE Smooth Surface Geomembrane for Artificial Lake |

|

|

| HDPE Smooth Surface Geomembrane for Golf Course Pond Bottom | HDPE Smooth Surface Geomembrane for Farming Pond |

Please Contact us to Get More Projects Cases, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

HDPE (High Density Polyethylene) Smooth Surface Geomembrane

- Below are the detailed information on HDPE smooth surface geomembrane for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- HDPE Smooth Surface Geomembrane

DownLoad

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.