Products+

Latest Products

Contact Us

- Shandong Greenland Engineering Material Co., Ltd.

- Mobile: +8615515596408(WhatsApp/Wechat)

- Email: Sales@glgeosynthetics.com

- Add: No. 69 Huanghe East Road, Yanggu County, Liaocheng City, Shandong Province, China 252000

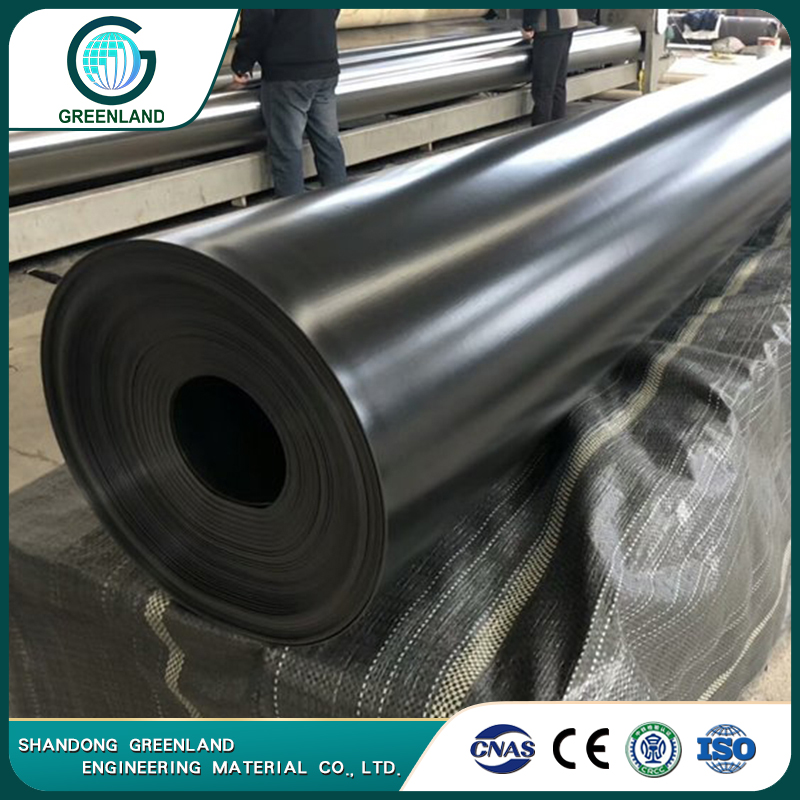

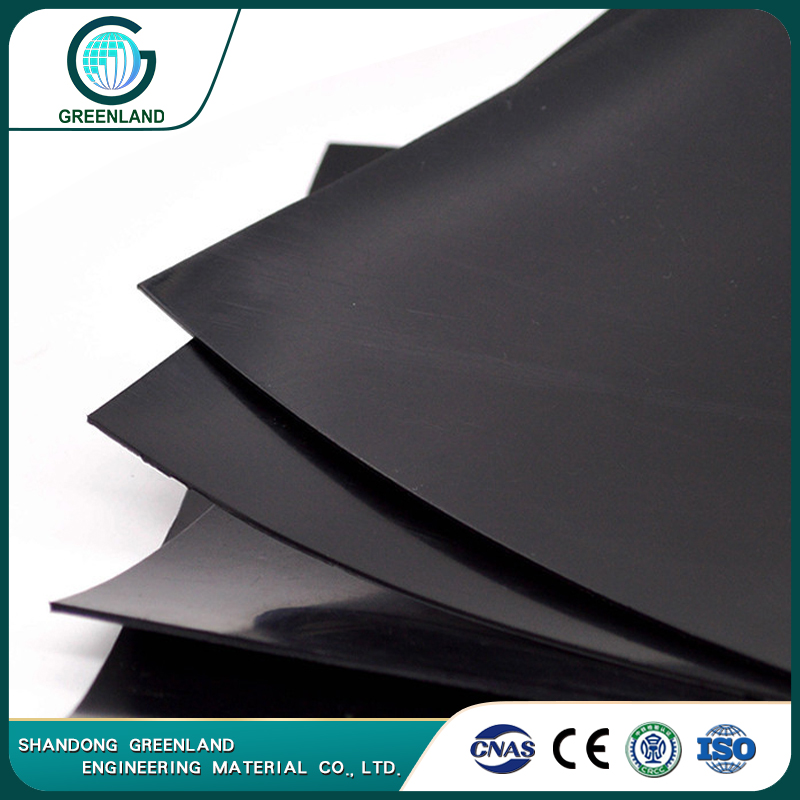

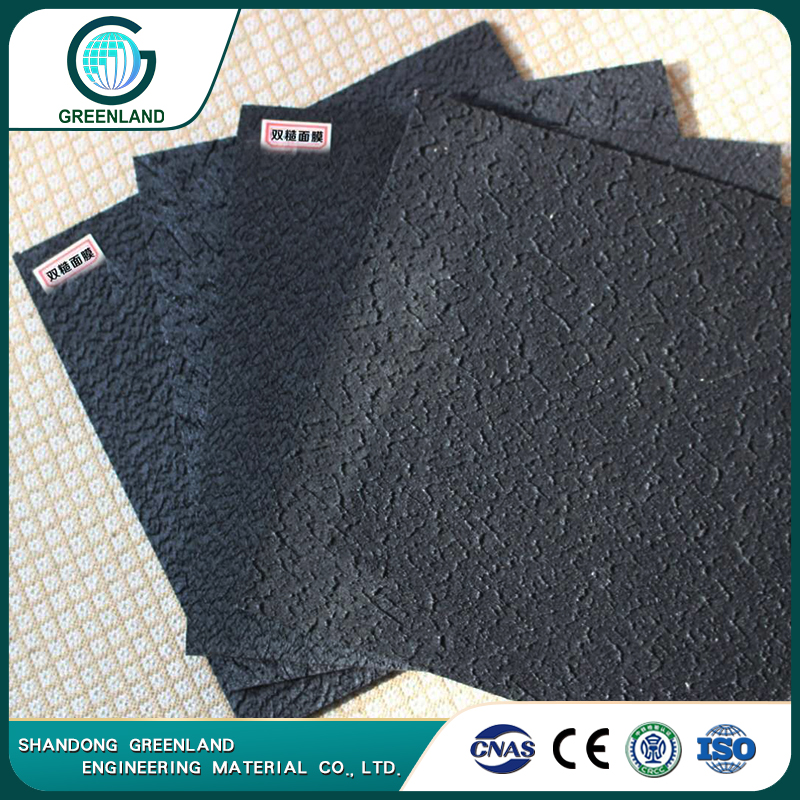

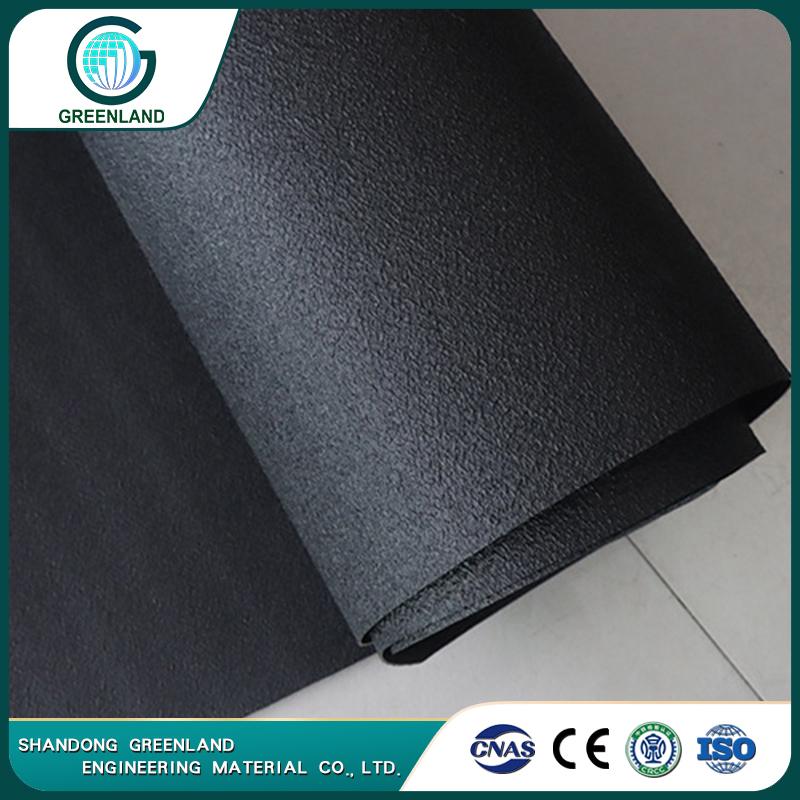

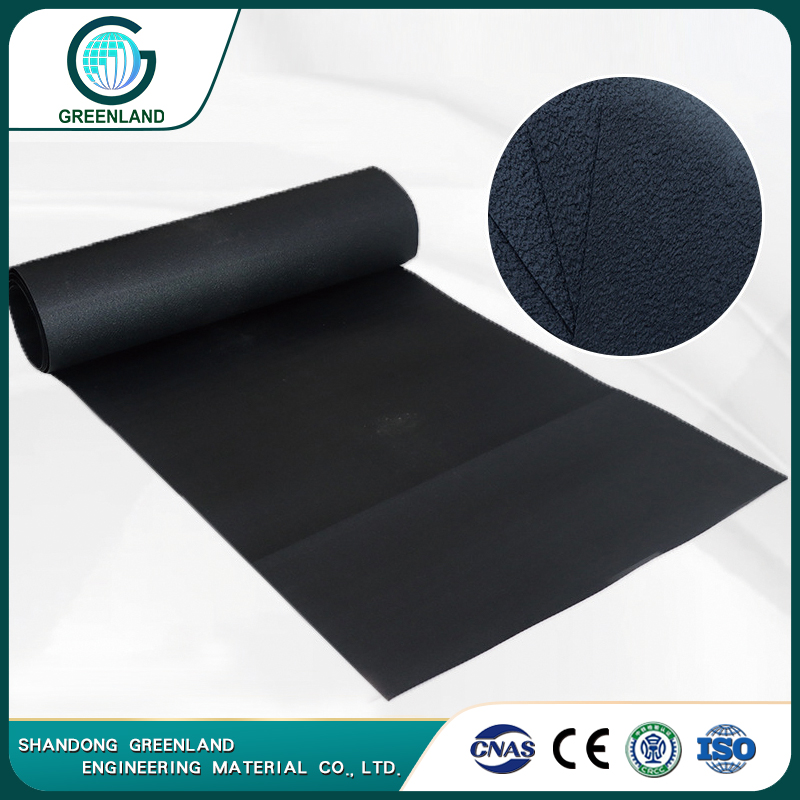

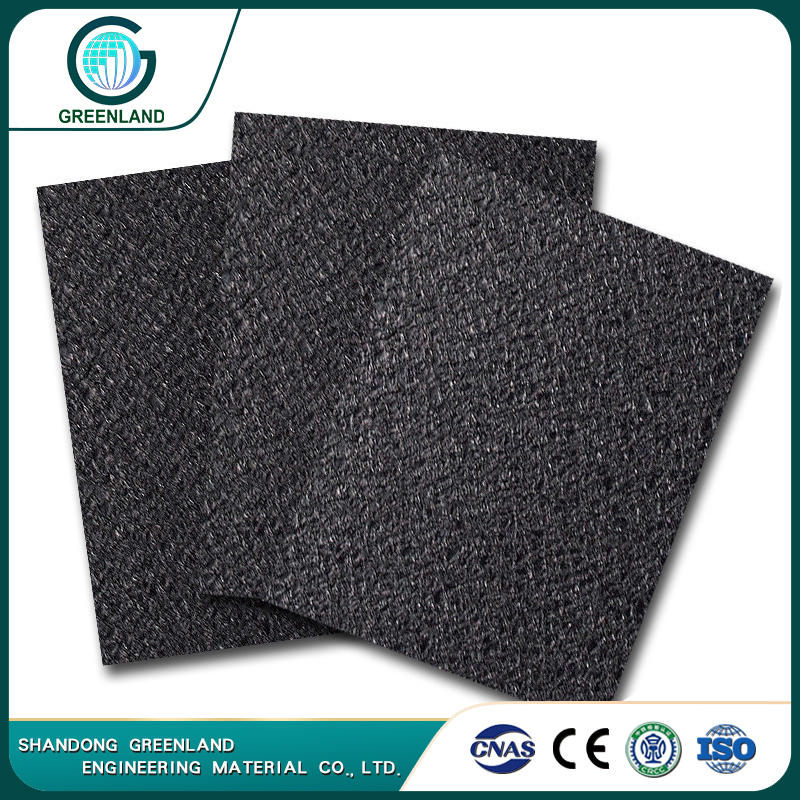

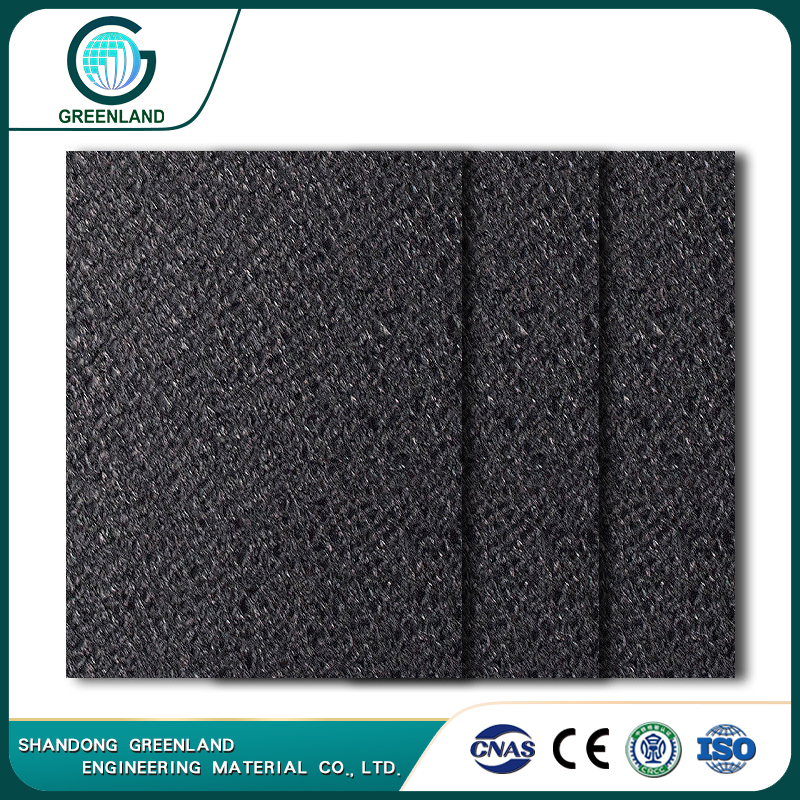

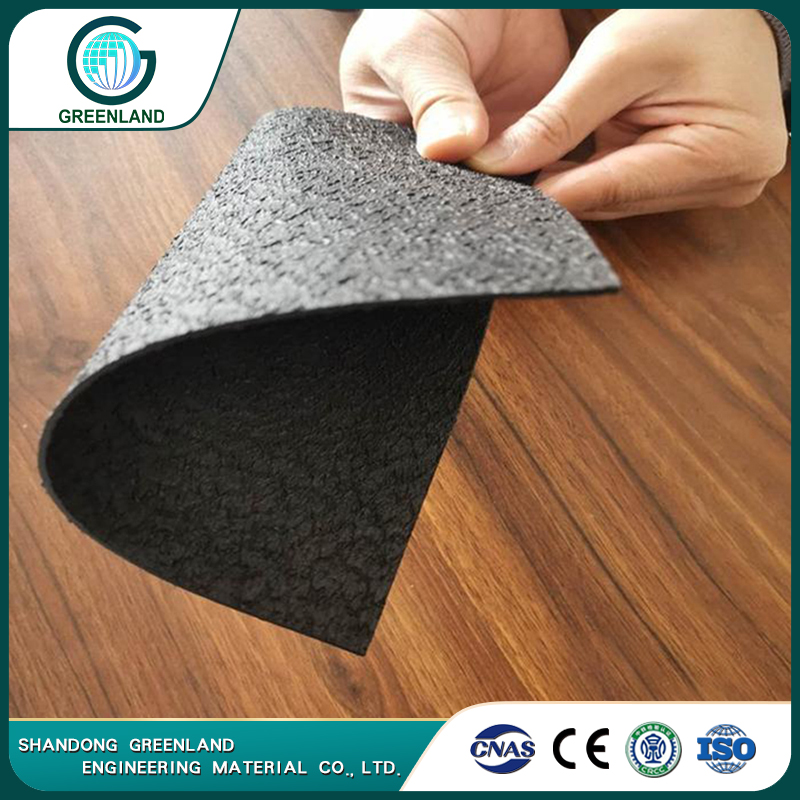

HDPE Double-Sided Textured Geomembrane

- 1.Thickness: 0.2mm-3.0mm(0.008inch-0.118inch)

- 2.Width: Max. 8M

- 3.Raw material: PE100, PE80, HDPE, LDPE, LLDPE, ECB, PVC, EVA…

- 4.Standards: ASTM GM13, ISO, GB/T17643-2011 GH-2T1、GH-2T2

- 5.Delivery period: stock, 5-10 days production date

- 6.Packing: 50-100m length/roll

- 7.MOQ: Trial order is acceptable

- 8.Free Sample

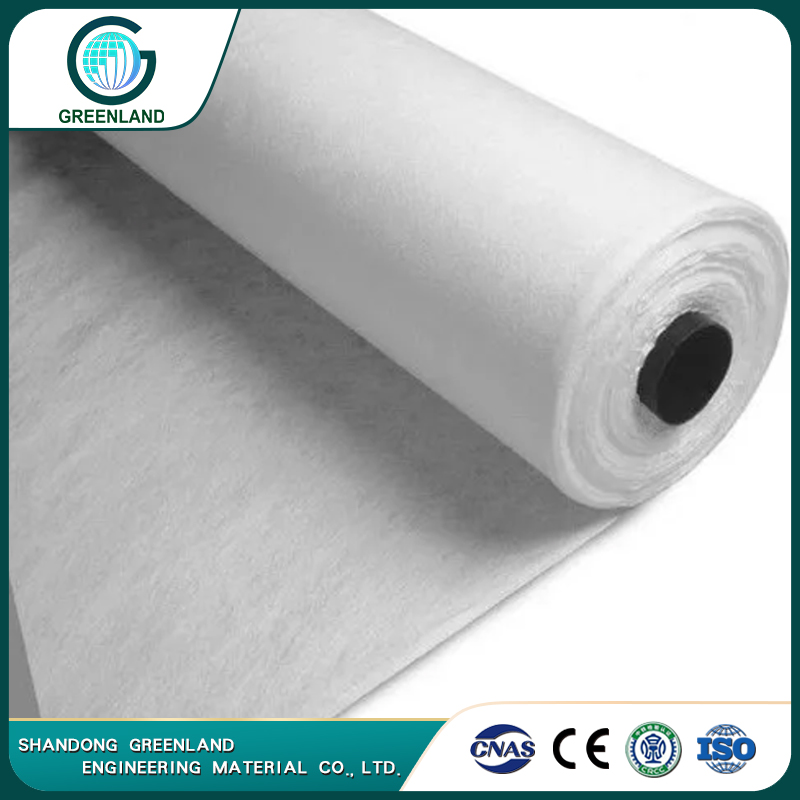

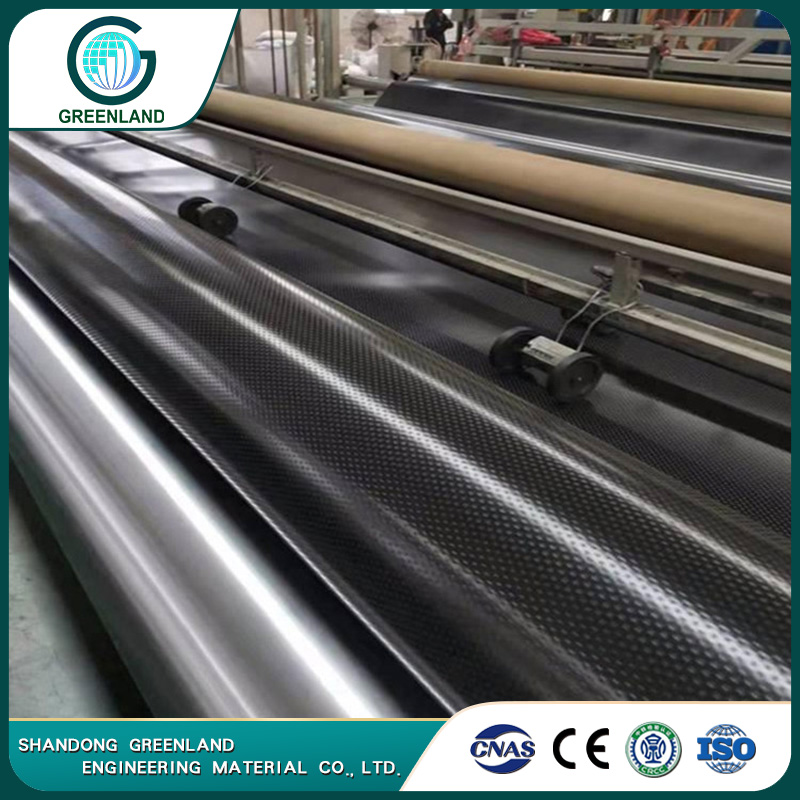

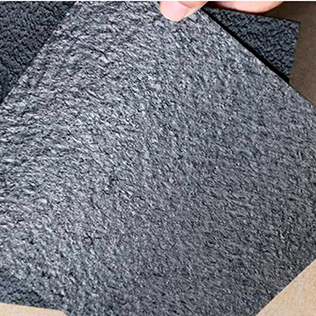

HDPE double-sided textured geomembrane is made of about 97.5% of high quality polyethylene, 2.5% carbon black, trace antioxidants and thermal stabilizers. The surface of the HDPE double-sided textured geomembrane is covered with a certain particle or texture. This treatment can increase the friction coefficient of the membrane, provide anti-slip effect, and increase the stability of the project.

HDPE double-sided textured geomembrane is often used in engineering projects such as land reinforcement, slope protection, soil and water conservation, and soil erosion prevention due to its anti slip and adhesion properties. In addition to the application scope of smooth surface geotextile, double-sided textured geomembrane is more suitable for various anti-seepage and anti-corrosion projects with certain inclination or anti slip and anti movement requirements, such as embankment slopes and slopes.

Quick Details of HDPE Double-Sided-Textured Geomembrane

Quick Details of HDPE Double-Sided-Textured Geomembrane

| Products details information | |

| Product name | HDPE Double-Sided Textured Geomembrane |

| Brand | Greenland (OEM is available) |

| Thickness | 0.2mm-3.0mm (0.008inch-0.118inch) |

| Raw material | HDPE, LDPE, LLDPE, EVA, PVC, ECB... |

| Application | Lining of landfills, river embankments, tailings dams, sewage dams, reservoirs, ditches, and other water ponds, subway, basement, tunnel anti-seepage and lining, anti-seepage lining of embankments and dams, vertical anti-seepage layer of the foundation, construction of cofferdams and fertilizer plants, seepage prevention in seawater and freshwater aquaculture ponds, waterproof layer for roads, highways, railway foundations, and expansive soil, roof anti-seepage and waterproof membrane. |

| Color | Black, White, other colors |

| Standards | ASTM GM13, ISO, GB/T17643-2011 GH-2T1、GH-2T2 |

| Welding Tools | Hot wind welding, roller welding machine, etc. |

| Company/Factory Strength | |

| Production Capacity | 120*40ft containers/month |

| Sample | Free sample could be provided |

| Quality | QA & QC system, Ensure traceability of each process |

| Warranty | 50-70 years service life |

| Certificates | ISO9001, OHSAS 18001, ISO14001,CE, CRCC |

| Delivery time | 5-30 days, depending on the quantity |

| Test/Inspection | National Standard Laboratory/ Pre-delivery inspection, Test Report |

| Service | Research, Design, Manufacture, Test, Sales, Solution Providing, After-sale service, Training |

| Management | Effective 8S Management System |

| No. of employees | More than 300 people |

❖Welcome customers to visit the factory, or third party factory inspection is acceptable.

Description of HDPE Double-Sided Textured Geomembrane

Description of HDPE Double-Sided Textured Geomembrane

HDPE double-sided textured geomembrane is rough through complex production processes and increase their friction coefficient to achieve anti-slip performance. HDPE double-sided textured geomembrane can be contacted with geofabrics in the construction of slope anti-seepage project construction to play a non-slip effect. HDPE double-sided textured geomembrane is usually used in projects where the slope membrane surface needs to be covered with soil and requires larger friction coefficients. It is very suitable for the slope pavement and the second pavement of the geotextile around the garbage landfill.

|

|

|

| Can withstand the pH environment | Large friction coefficient | Good heat-resistant and cold-resistant |

|

|

|

| High resistance to tension | Long service life | Convenient construction |

Benefits of HDPE Double-Sided Textured Geomembrane

Benefits of HDPE Double-Sided Textured Geomembrane

HDPE double-sided textured geomembrane has excellent anti-seepage and anti-fouling performance as well as mechanical properties, including resistance to stress cracking, tear strength, and puncture resistance; Good dimensional stability, chemical stability, heat resistance, and aging resistance; Good tensile properties (yield strength, fracture strength, yield elongation, fracture elongation). At the same time, it also has excellent resistance to ultraviolet radiation, high friction coefficient, good skid resistance, wear resistance, good barrier properties, and good bonding performance.

Please Contact us to Get More Details, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

Specifications of HDPE Double-Sided Textured Geomembrane

Specifications of HDPE Double-Sided Textured Geomembrane

Environmentally Friendly HDPE Double-Sided Textured Geomembrane <GB/T17643-2011 GH-2T1 And GH-2T2 Technical Specifications

| Number | Item | Indicators | ||||||

| Thickness (mm) | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | |

| 1 | Density (g/m³) | ≥0.940 | ||||||

| 2 | Roughness height (mm) | ≥0.25 | ||||||

| 3 | Tensile yield strength (longitudinal and transverse) N/mm | ≥11 | ≥15 | ≥18 | ≥22 | ≥29 | ≥37 | ≥44 |

| 4 | Tensile fracture strength (longitudinal and transverse) N/mm | ≥8 | ≥10 | ≥13 | ≥16 | ≥21 | ≥26 | ≥32 |

| 5 | Yield elongation (longitudinal and transverse) % | ≥12 | ||||||

| 6 | Elongation at break (longitudinal and transverse) % | ≥100 | ||||||

| 7 | Right angle tear load (longitudinal and transverse) N | ≥93 | ≥125 | ≥160 | ≥190 | ≥250 | ≥315 | ≥375 |

| 8 | Puncture resistance strength N | ≥200 | ≥270 | ≥335 | ≥400 | ≥535 | ≥670 | ≥800 |

| 9 | Tensile load stress cracking (notch constant load tensile method) h | ≥300 | ||||||

| 10 | Carbon black content % | 2.0~3.0 | ||||||

| 11 | Carbon black dispersibility | Out of 10 data points, there should be no more than 1 level 3, and levels 4 and 5 are not allowed. | ||||||

| 12 | oxidation induction time (OIT)(min) | Induction time of atmospheric pressure oxidation≥100 | ||||||

| Induction time of high-pressure oxidation≥400 | ||||||||

| 13 | 85 ℃ thermal aging (atmospheric pressure OIT retention rate after 90 days) | ≥55 | ||||||

| 14 | UV resistance (OIT retention rate after 1600 hours of UV irradiation) % | ≥50 | ||||||

| Note: The technical performance indicators for thickness specifications not listed in the table are required to be executed using interpolation method. | ||||||||

HDPE Double-Sided Textured Geomembrane ASTM Standard

| ASTM GM13 HDPE Geomembrane-Textured | |||||||

| Properties | Test Method (ASTM) |

Test Value | |||||

| 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.0mm | ||

| Asperity Height | D7466 | 0.25mm | 0.25mm | 0.25mm | 0.25mm | 0.25mm | 0.25mm |

| Density | D 792 | 0.940 g/cm3 | 0.940 g/cm3 | 0.940 g/cm3 | 0.940 g/cm3 | 0.940 g/cm3 | 0.940 g/cm3 |

| Tensile properties Streneth at Yield N/mm Strength at Break N/mm GElongation at Yield % Elongation at Break % |

D6693 Tvpe IV |

15 10 12 700 |

18 13 12 700 |

22 16 12 700 |

29 21 12 700 |

37 26 12 700 |

44 32 12 700 |

| Tear Resistance | D 1004 | 125 N | 156 N | 187N | 249 N | 311 N | 374 N |

| Puncture Resistance | D 4833 | 267N | 333N | 400N | 534 N | 667 N | 800N |

| Stress Crack Resistance | D 5397 | 500hr. | 500 hr. | 500 hr. | 500 hr. | 500hr. | 500 hr. |

| Carbon Black Content | D 1603 | 2.0-3.0% | 2 0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% | 2.0-3.0% |

| Oxidative Induction Time (OIT) Standard OIT High Pressure OIT |

D 3895 D 5885 |

100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

| 400min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | ||

| Oven Aging at 85 ℃ Standard OIT retained after 90 days High Pressure OIT retained after 90 days |

D 5721 D 3895 D 3895 |

55% | 55% | 55% | 55% | 55% | 55% |

| 80% | 80% | 80% | 80% | 80% | 80% | ||

| UV Resistance Standard OIT High Pressure OIT |

D 3895 D 5885 |

50% | 50% | 50% | 50% | 50% | 50% |

| 50% | 50% | 50% | 50% | 50% | 50% | ||

Other specifications have not been shown on our dimension chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

HDPE double-sided textured geomembrane is mainly used for lining of landfills, river embankments, tailings dams, sewage dams, reservoirs, ditches, and other water ponds; Subway, basement, tunnel anti-seepage and lining; The anti-seepage lining of embankments and dams; Vertical anti-seepage layer of the foundation; Construction of cofferdams and fertilizer plants; Seepage prevention in seawater and freshwater aquaculture ponds; Waterproof layer for roads, highways, railway foundations, and expansive soil; Roof anti-seepage and waterproof membrane.

❖HDPE Double-Sided Textured Geomembrane for Waterproof & Anti-seepage

1.Water conservancy

2.Landscape garden

3.Agriculture

|

|

| HDPE Double-Sided Textured Geomembrane for Embankment | HDPE Double-Sided Textured Geomembrane for Artificial Lake |

|

|

| HDPE Double-Sided Textured Geomembrane for Slope Protection | HDPE Double-Sided Textured Geomembrane for Agricultural Reservoirs |

Please Contact us to Get More Projects Cases, Send Email: sales@glgeosynthetics.com. or Mobile:(WhatsApp): +86 155 15596408.

HDPE Double-Sided Textured Geomembrane

- Below are the detailed information on HDPE Double-Sided Textured Geomembrane for your reference, Online preview and Download.

- Please contact us to get Products Catalog, Technical Data Sheet, GET QUOTATION and the LATEST PRICE LIST now, Email: sales@glgeosynthetics.com. Mobile(WhatsApp): +86 155 15596408.

- HDPE Double-Sided Textured Geomembrane

DownLoad

Other CUSTOMIZED Fittings have not been shown on above chart, please CONTACT US for more information

Please Send Email: sales@glgeosynthetics.com or Mobile:(WhatsApp): +86 155 15596408.

Write Down Your Question

We are not only a product manufacturer, also a solution provider, whether you have a Question or Request For Quotations, we're here to help.